Train bogie bearing service process monitoring and fault diagnosis system and method

A fault diagnosis system and process monitoring technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of inconvenient sampling, etc., achieve the effect of convenient installation, good engineering implementation, and avoid high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

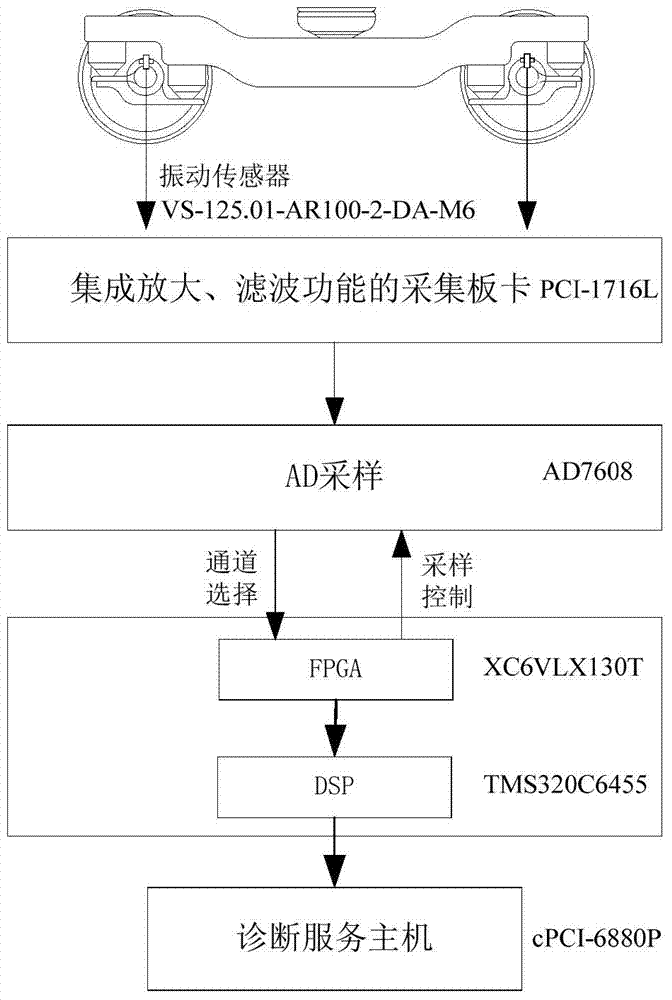

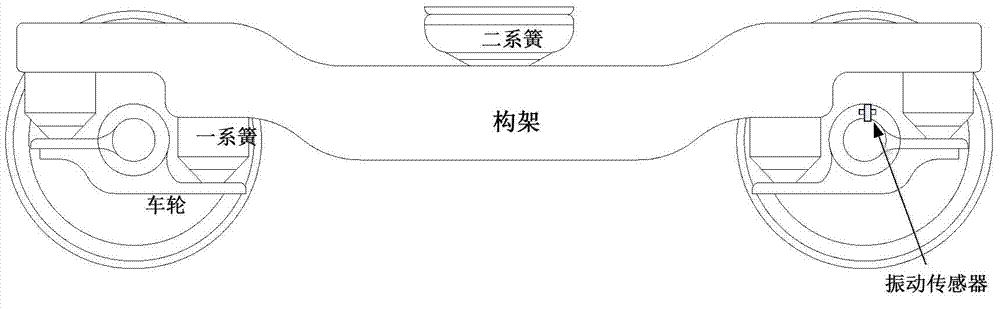

Method used

Image

Examples

Embodiment 1

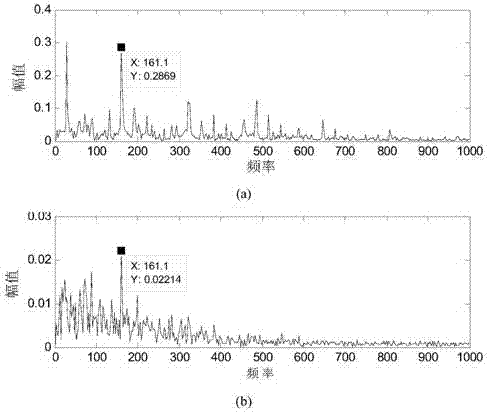

[0088] The bearing used in this experiment is SKF's 6205 deep groove ball bearing. The acceleration vibration sensor is used to collect vibration data. The sampling frequency is 12K / s. The experimental bearing has a single point fault in EDM. The fault size is 0.014 inches, which is calculated by empirical formula The fault frequency is obtained to be 161Hz. The original signal collected contains a lot of burr details, which is the noise interference of bearing vibration. These noises are filtered out by singular value decomposition. The signal after denoising processing is as follows: Figure 5 shown;

[0089] Perform FFT transformation on the denoised signal to obtain the frequency domain image 6, by Figure 6 It can be seen that the signal mainly concentrates most of the frequency components within 1000Hz and near 3000Hz, which are the fault characteristic frequency and natural vibration frequency of the signal respectively;

[0090] The vibration signal is decomposed by E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com