Optical fiber coloring take-up and pay-off tension control system

A tension control, winding and unwinding technology, applied in control/adjustment systems, mechanical pressure/force control, non-electric variable control, etc., can solve the problems of cable core relaxation, uneven coloring, waste of manpower and material resources, etc Balanced line tension and beautiful man-machine interface

Inactive Publication Date: 2014-12-24

QINGDAO KANGWEILONG COMMODITY COMPANY

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In recent years, with the progress of society and the improvement of people's material and spiritual life quality, my country's information industry is developing rapidly, the society's demand for optical cables is increasing, and optical cables are the urgent needs of information networks; in the process of producing optical cables , due to the low strength, low hardness and strong flexibility of each fiber core, when the fiber core is colored, due to the change of the movement speed of the cable core, sometimes there will be uneven coloring or the phenomenon of cable core relaxation, which will cause the cable core to be colored The uniformity and stability of the cable are affected, and manual intervention is required to allow the cable core to enter the coloring device smoothly, wasting manpower and material resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

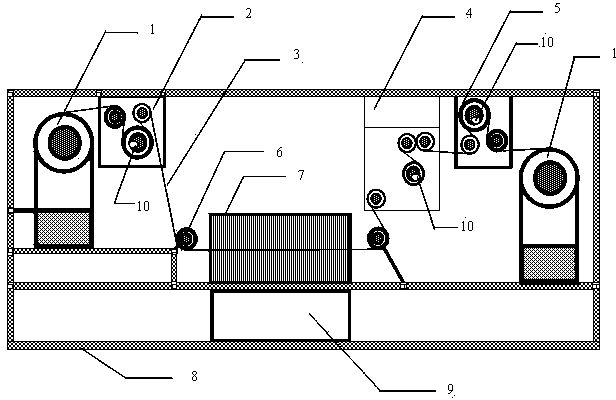

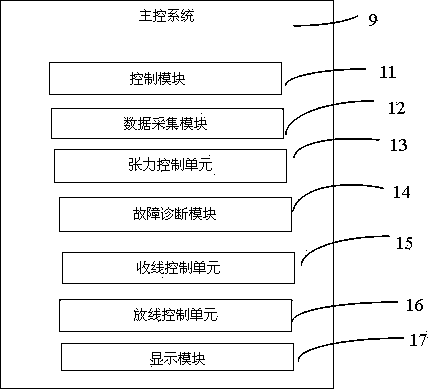

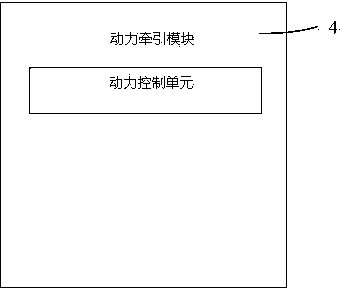

The invention relates to an optical fiber coloring take-up and pay-off tension control system. The optical fiber coloring take-up and pay-off tension control system comprises a master control system, a sensor group, a power traction module, a pay-off device, a take-up device, two optical fiber core plates, a set of pulleys and a mechanical support. The master control system is in charge of controlling and managing the whole optical fiber coloring take-up and pay-off tension control system, and comprises a control module, a data acquisition module, a tension control unit, a fault diagnosis module, a take-up control unit, a pay-off control unit and a display module. The power traction module is in charge of executing commands and motions of the master control system, and comprises a power control unit, a pay-off command issuing unit and a take-up command issuing unit. The optical fiber coloring take-up and pay-off tension control system can balance optical fiber take-up and pay-off tension, keeps the coloring rate between 600m / min and 1500m / min, makes a human-machine interface be beautiful, and has a fault alarm function.

Description

technical field [0001] The invention belongs to the technical field of optical cable preparation, and in particular relates to a tension control system for optical fiber coloring take-up and take-off lines. [0002] Background technique [0003] In recent years, with the progress of society and the improvement of people's material and spiritual life quality, my country's information industry is developing rapidly, the society's demand for optical cables is increasing, and optical cables are the urgent needs of information networks; in the process of producing optical cables , due to the low strength, low hardness and strong flexibility of each fiber core, when the fiber core is colored, due to the change of the movement speed of the cable core, sometimes there will be uneven coloring or the phenomenon of cable core relaxation, which will cause the cable core to be colored The uniformity and stability of the cable are affected, and manual intervention is required to allow the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B6/44G05D15/01

Inventor 解云龙

Owner QINGDAO KANGWEILONG COMMODITY COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com