Cantilever beam vibration control method on basis of self-adaption neural network control

A technology of neural network control and cantilever beam, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as model uncertainty, parameter perturbation and external disturbance force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended invention purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

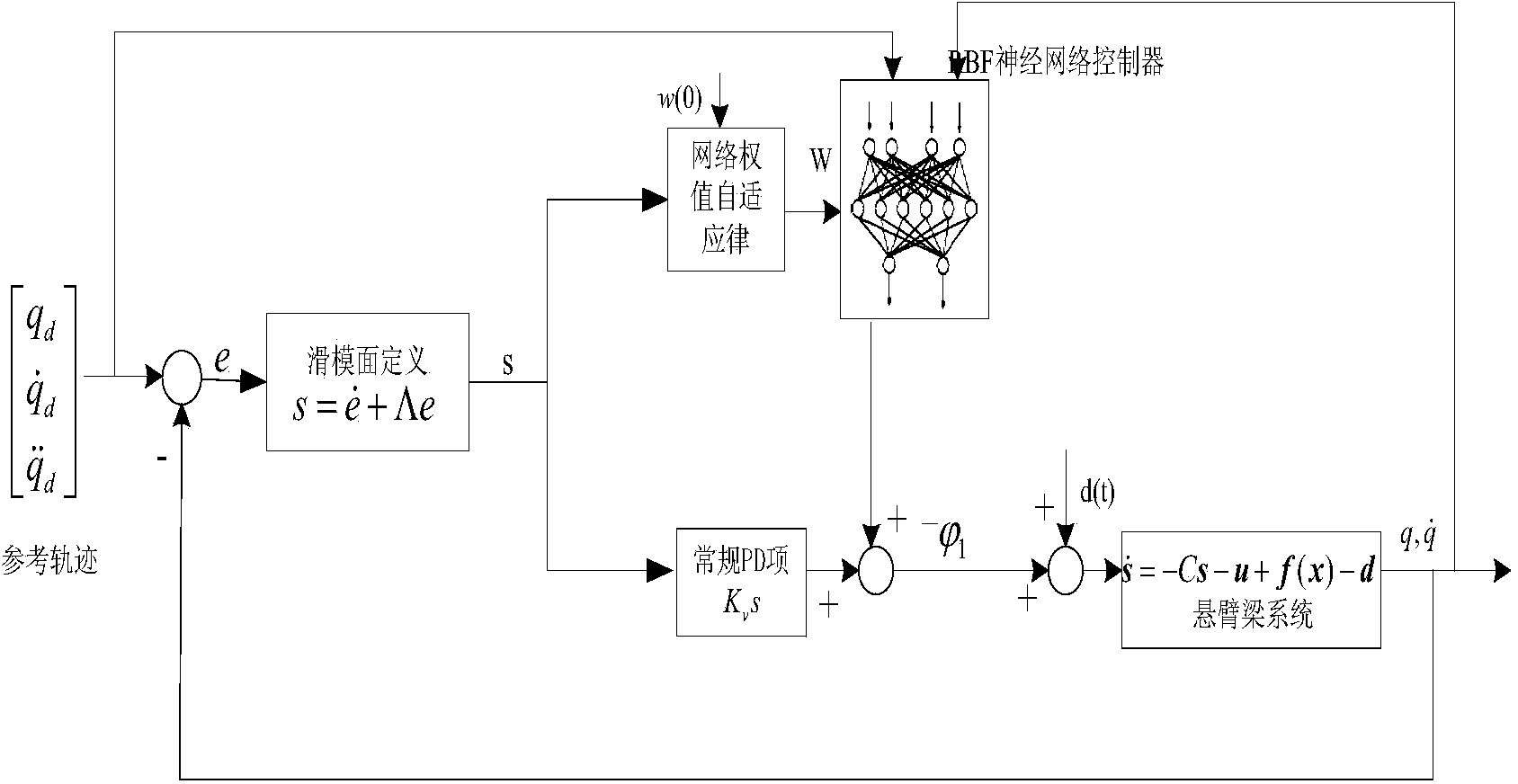

[0056] The vibration control principle of a cantilever beam based on adaptive neural network control of the present invention is as follows: figure 1 As shown, it includes the following parts:

[0057] (1) Establish a filter error model based on cantilever beam

[0058]The vector form of the cantilever beam dynamics model:

[0059] q . . + C q . + Kq = u + d - - - ( 1 )

[0060] where C,K∈R i*i is the system parameter, where C is the damping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com