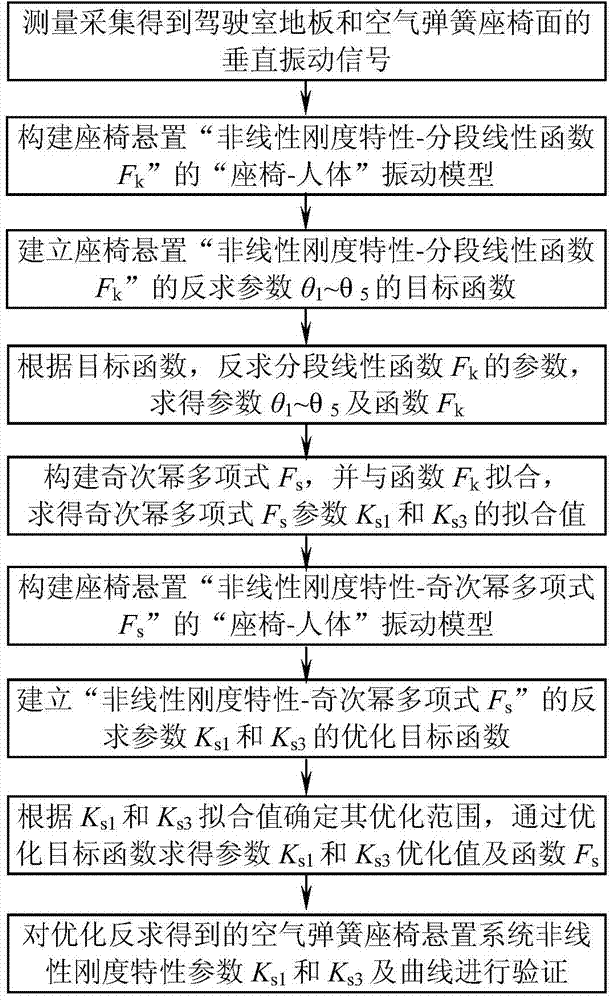

Inverse solution method for nonlinear stiffness characteristic parameters and curve of suspension of air spring seat

A technology of stiffness characteristics and air springs, applied in special data processing applications, electrical digital data processing, instruments, etc., can solve the problems of long cycle, inability to search for ideal values, high test costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail through an embodiment below.

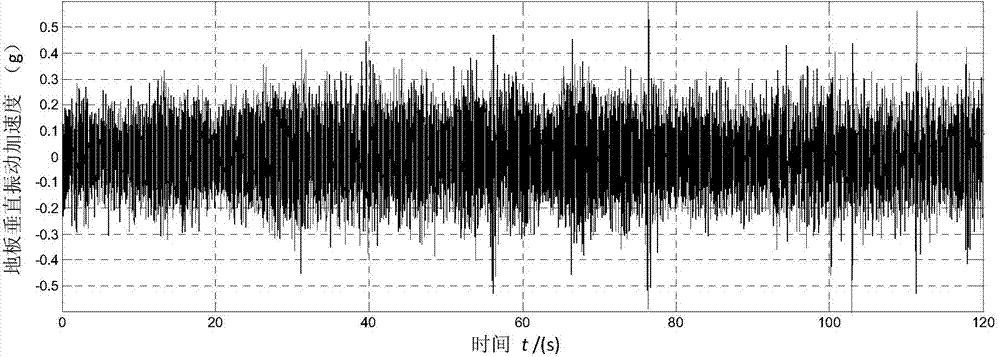

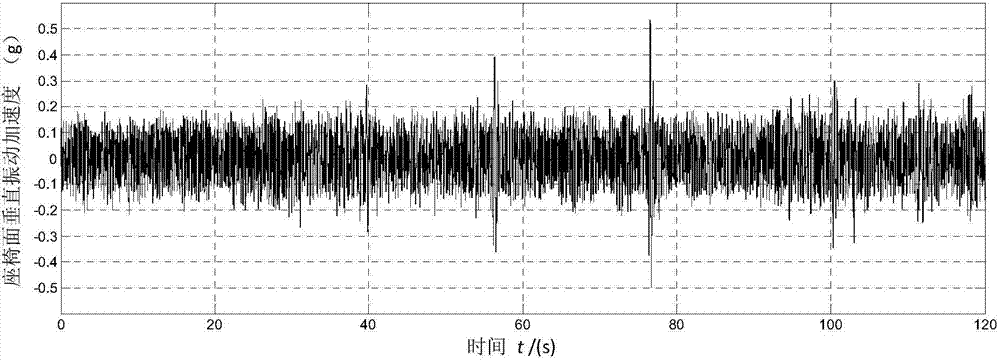

[0039] An air spring suspension is installed in the seating system of a truck. In order to meet the requirements of comfort analysis and parameter optimization design of the seat suspension system, it is necessary to obtain the nonlinear stiffness characteristic curve of the air spring seat suspension system, so as to optimize the design of the seat suspension system. In the air spring seat system of the truck, the equivalent stiffness K of the seat cushion is known h =31000N / m and equivalent damping C h =530Nm / s, the equivalent damping C of the seat suspension s =1000Nm / s, equivalent stiffness of human body K b =26000N / m and equivalent damping C b =700Nm / s, the equivalent mass of the upper part of the human body m b = 48kg and the equivalent mass of human buttocks m h = 15kg, the sum of the mass of the seat and cushion m s = 20kg, the vertical relative maximum displacement a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com