Wideband filter adopting single-cavity five-mode cavity resonator

A resonator and filter technology, applied to waveguide devices, electrical components, circuits, etc., can solve problems such as the complexity of simulation debugging, large influence of main mode, narrow filter bandwidth, etc., and meet the requirements of miniaturized communication and wide fraction Effects of bandwidth, design and processing simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

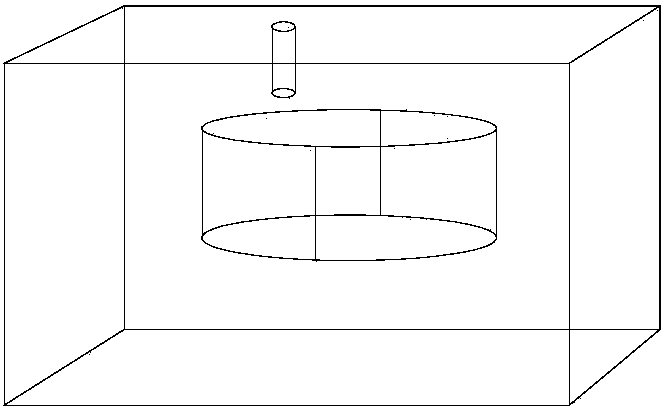

[0046] like Figure 5 ~ Figure 10 As shown, the filter of this embodiment includes a cavity 1, a first port 2, a second port 3, a first perturbation metal body 4, a second perturbation metal body 5 and a third perturbation metal body 6. The The cavity 1 is a cylindrical cavity, the shape of the first perturbation metal body 4, the second perturbation metal body 5 and the third perturbation metal body 6 is a cylinder, and the first port 2 and the second port 3 are both Can be used as input port and output port;

[0047] The bottom surface of the first perturbation metal body 4 is provided with a first fixing / tuning screw 7 which is integral with the first perturbation metal body 4 , and the bottom surface of the second perturbation metal body 5 is provided with the first fixing / tuning screw 7 . The two perturbation metal bodies 5 form an integral second fixing / tuning screw 8, and the bottom surface of the third perturbation metal body 6 is provided with a third fixing / tuning s...

Embodiment 2

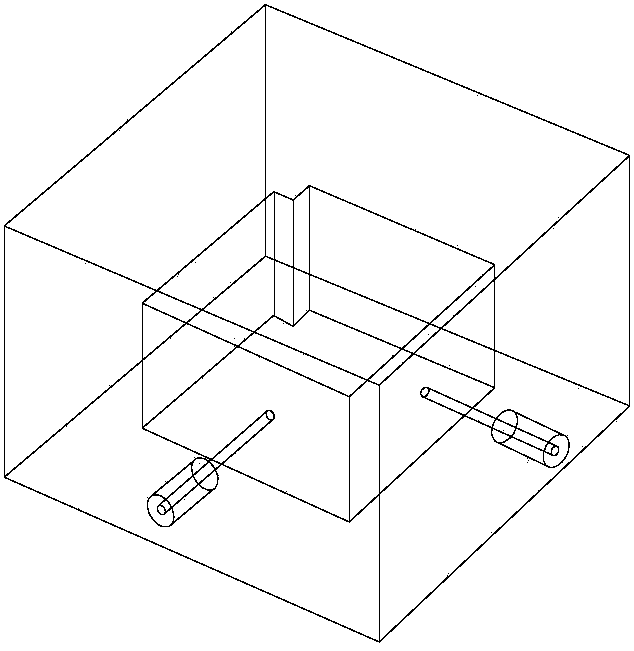

[0053] The main features of this embodiment are: Figure 16 As shown, the cavity 1 is a rectangular cavity, and the first perturbation metal body 4, the second perturbation metal body 5 and the third perturbation metal body 6 are all cylindrical in shape; the first port 2 and the second port 3 can be respectively set on any two mutually perpendicular surfaces of the cavity 1 except the top surface and the bottom surface (in this embodiment, the first port 2 is set on the front of the cavity 1, and the second port 3 is set on the On the right side of the cavity 1, and both the first port 2 and the second port 3 are at a distance from the top and bottom surfaces of the cavity 1); and the processing process is also to take a rectangular body, cut the bottom part, The bottom of the cut is a closed bottom plate, and a rectangular cavity is dug out of the remaining uncut part to form an upper cavity. The rest are the same as in Example 1.

Embodiment 3

[0055] The main features of this embodiment are: Figure 17 As shown, the cavity 1 is a cylindrical cavity, and the first perturbation metal body 4 , the second perturbation metal body 5 and the third perturbation metal body 6 are all rectangular in shape. The rest are the same as in Example 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com