Arrangement with a fuel distributer and multiple fuel injection valves

一种燃料喷射阀、燃料分配器的技术,应用在具有降低噪音措施的燃料喷射装置、燃料喷射装置、特殊燃料喷射装置等方向,能够解决侵入车辆等问题,达到有效阻尼、减小噪声发射、均匀加载的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

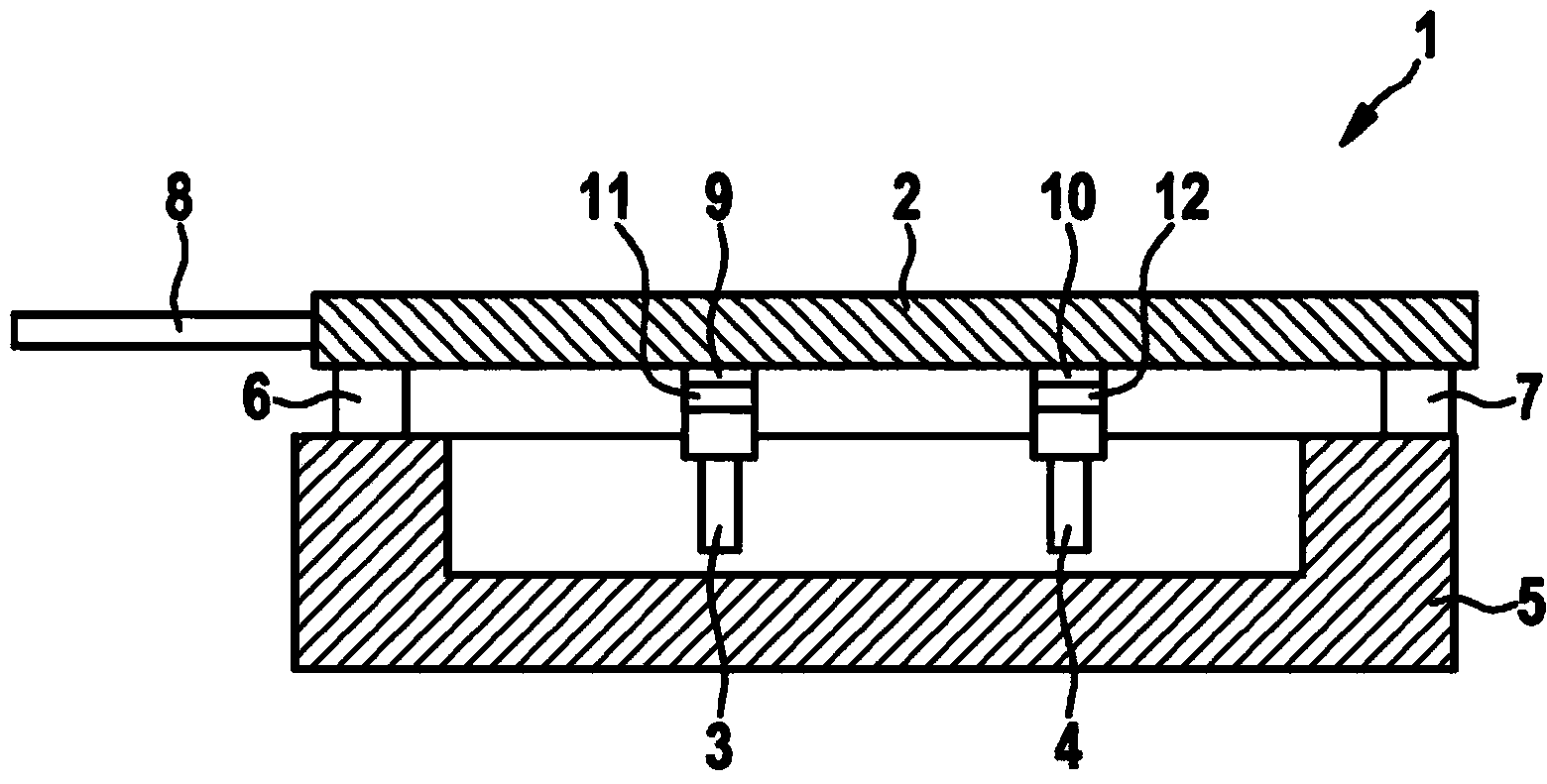

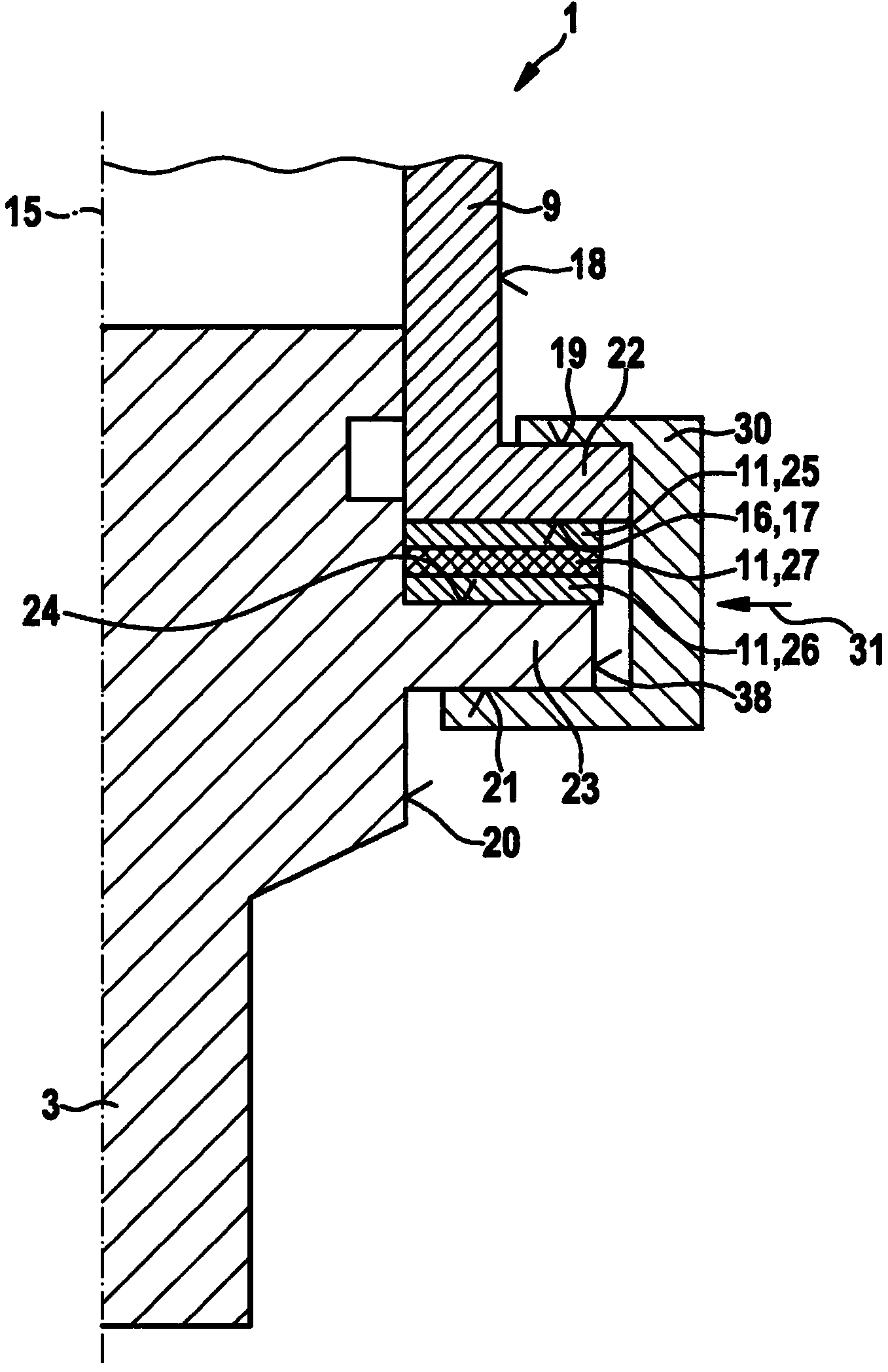

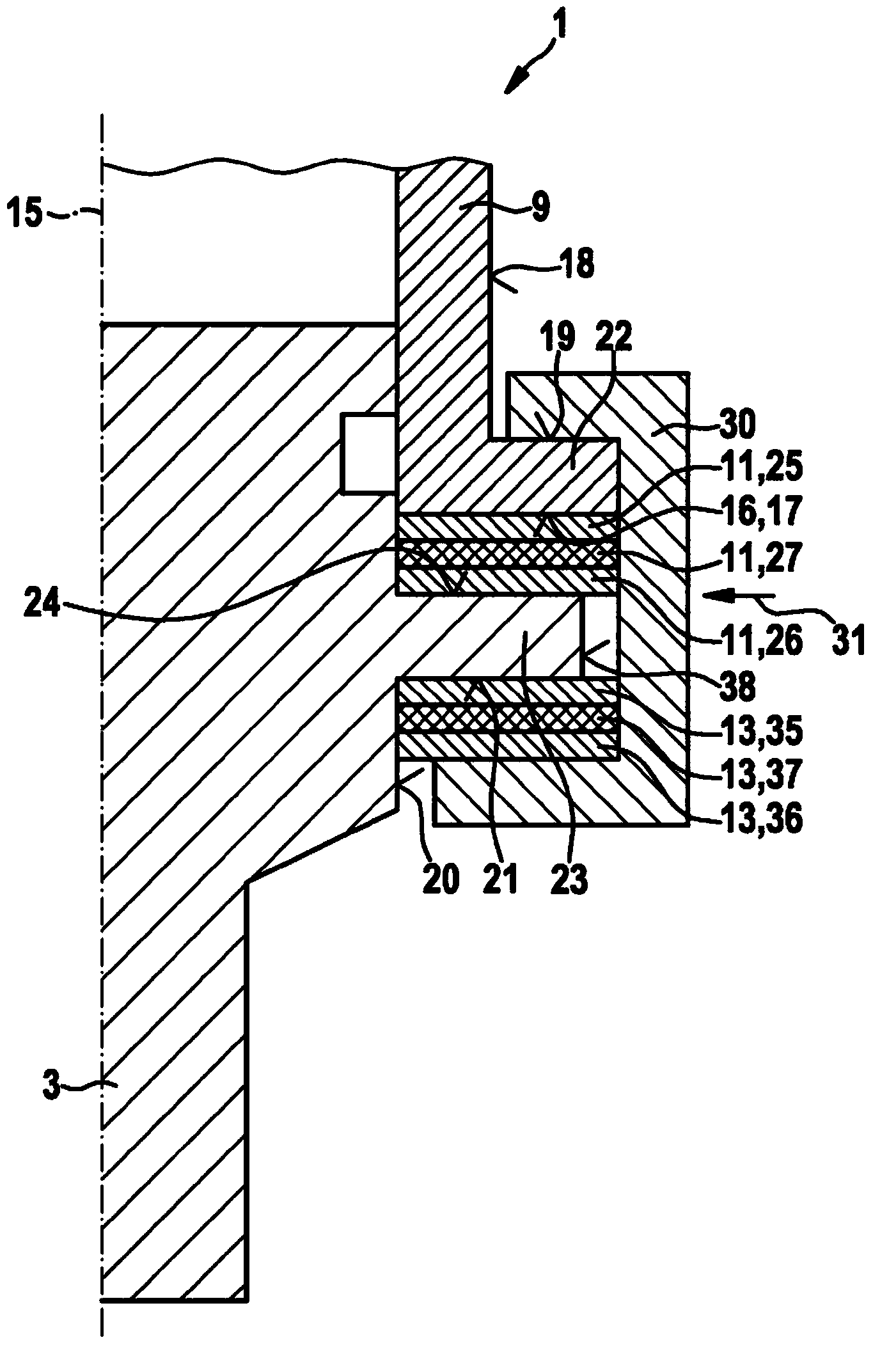

[0025] exist figure 1 An arrangement 1 with a fuel distributor 2 and a plurality of fuel injection valves 3 , 4 is shown in . The fuel distributor 2 can in particular be designed as a fuel distribution strip. The fuel distributor 2 is used to store high-pressure fuel and to distribute the fuel to a plurality of fuel injection valves 3 , 4 . In order to simplify the illustration, only two fuel injection valves 3 , 4 are shown in this exemplary embodiment. The number of fuel injection valves 3 , 4 connected to fuel distributor 2 depends on the number of cylinders of the internal combustion engine. The fuel distributor 2 is connected in a suitable manner to a mounting structure 5 , in particular to a cylinder head 5 . The fuel distributor 2 can also be connected via spacer bushes or via other connection elements 6 , 7 . Furthermore, a high-pressure line 8 is provided, which is connected to the fuel distributor 2 . The high-pressure line 8 serves to deliver high-pressure fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com