Negative electrode active material comprising porous silicon oxide-carbon material composite and preparation method thereof

A negative electrode active material and oxide technology, which is applied in the field of negative electrode active materials comprising porous silicon oxide-carbon material composites and their preparation, can solve the problems of cycle characteristics and lifespan decline, uneven distribution of graphite, etc., and achieve improved lifespan properties, improved conductivity, improved resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of porous silicon oxide-carbon material composite 1

[0050] Porous SiO was impregnated in an aqueous solution containing iron nitrate. Next, the iron catalyst was bound to the surface and inside of the pores of the porous silicon oxide by drying the mixture thus obtained.

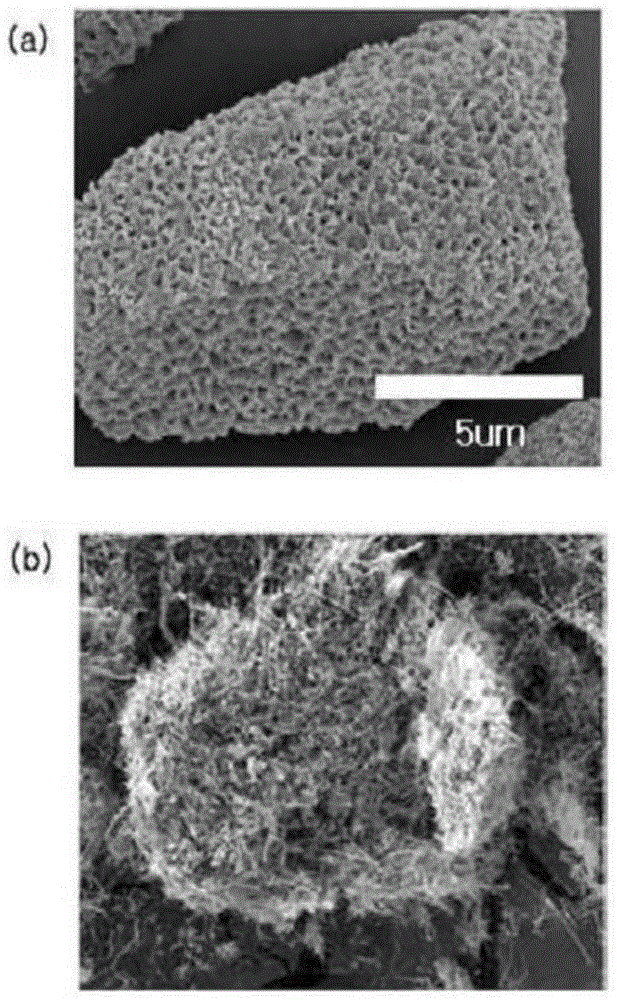

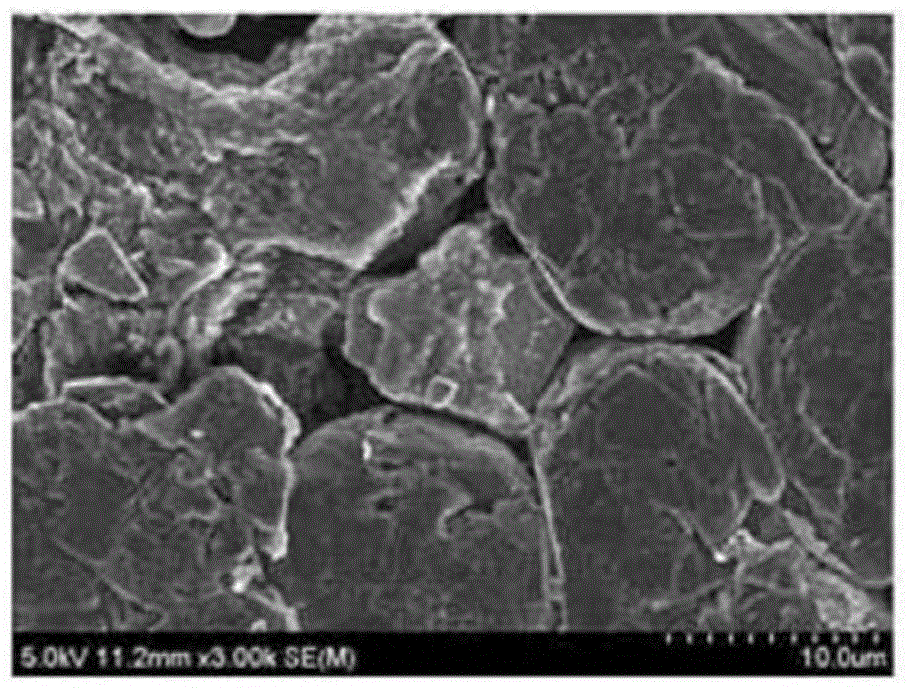

[0051] The porous silicon oxide combined with the metal catalyst was put into a CVD chamber, and then a mixed gas containing hydrocarbon gas such as ethane and inert gas such as nitrogen, helium, and argon was supplied, and heated at 800° C. Carbon nanotubes (CNTs) are formed on the surface and inside the pores. Thus, a porous silicon oxide-carbon material composite was prepared.

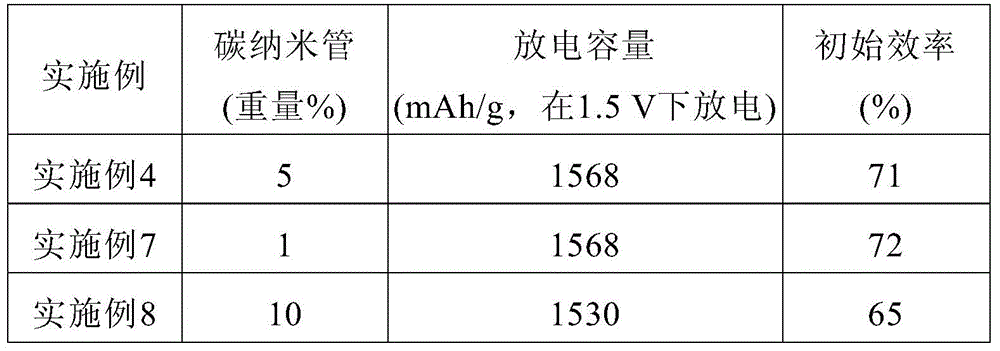

[0052] In this case, the amount of carbon nanotubes was 5% by weight based on 100% by weight of the porous silicon oxide-carbon material composite. In addition, the average diameter of the carbon nanotubes was 50 nm, and the average length thereof was 2 μm. The average diameter of the pores cont...

Embodiment 2

[0053] Embodiment 2: Preparation 2 of porous silicon oxide-carbon material composite

[0054] A porous silicon oxide-carbon material composite was prepared in the same manner as in Example 1, except that, based on 100% by weight of the porous silicon oxide-carbon material composite, the amount of carbon nanotubes formed was 1 weight%. The average diameter of the pores contained in the porous silicon oxide-carbon material composite was about 200 nm when measured from the surface of the composite using SEM.

Embodiment 3

[0055] Embodiment 3: Preparation 3 of porous silicon oxide-carbon material composite

[0056] A porous silicon oxide-carbon material composite was prepared in the same manner as in Example 1, except that, based on 100% by weight of the porous silicon oxide-carbon material composite, the amount of carbon nanotubes formed was 10 weight%. The average diameter of the pores contained in the porous silicon oxide-carbon material composite was about 200 nm when measured from the surface of the composite using SEM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com