DC motors for driving motor vehicle components

A technology of DC motors and motor vehicles, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., and can solve problems such as electromagnetic radiation interference, damage to radio reception or radio communication, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

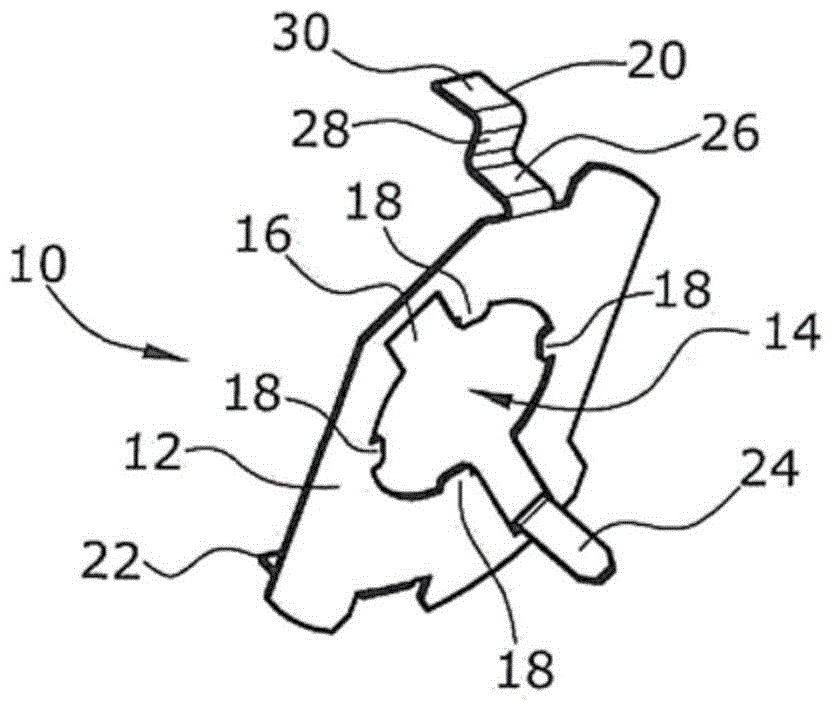

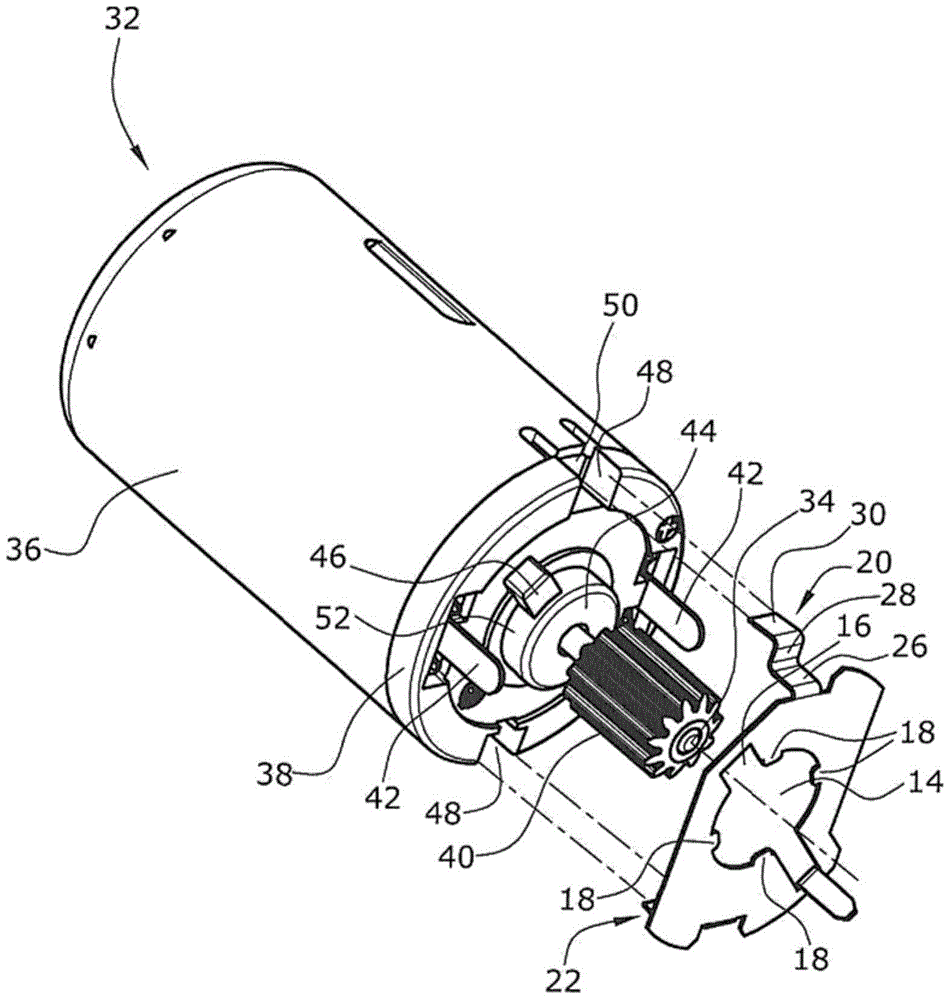

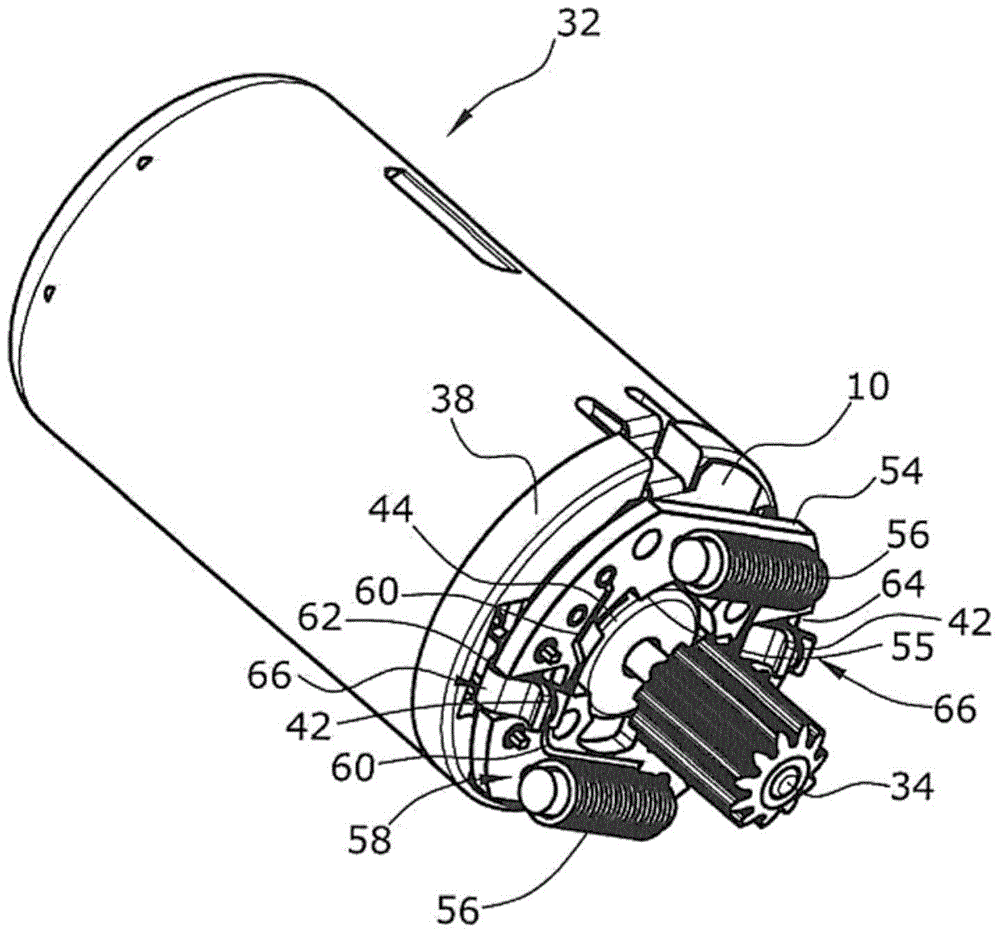

[0022] figure 1 A sheet metal part 10 is shown, which is produced by a stamping and bending process. The plate consists of a base plate 12 with a centrally located, substantially circular opening 14 which is expanded laterally in such a way that a rectangular non-central opening 16 also extends from the circular opening 14 to extend outside. Four flanges 18 offset at 90° from each other extend radially inwards from the radially inner edge of the base plate 12 towards the circular opening 14 .

[0023] In this embodiment, a total of three contact elements 20 , 22 , 24 extend axially starting from the radially outer edge region of the base plate 12 . The two first contact pieces 20 , 22 are arranged substantially offset by 180° and extend parallel to each other in the first axial direction. The two first contact pieces 20 , 22 have a first section 26 extending axially and a second section 28 extending radially outwards from the first section, so that The second section is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com