System and corresponding process for manufacturing bobbin paper

A production system, technology of bobbin paper, applied in the field of papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1 bobbin paper production system

[0095] A bobbin paper production system includes a high-grade bobbin paper production line and a middle-grade bobbin paper production line.

[0096] 1. High-grade bobbin paper production line includes pulping module Ⅰ and papermaking module Ⅰ.

[0097] (1) Pulping Module I

[0098] Pulping module I includes pulping equipment I for manufacturing pulp y made from waste cardboard, such as Figure 5 shown.

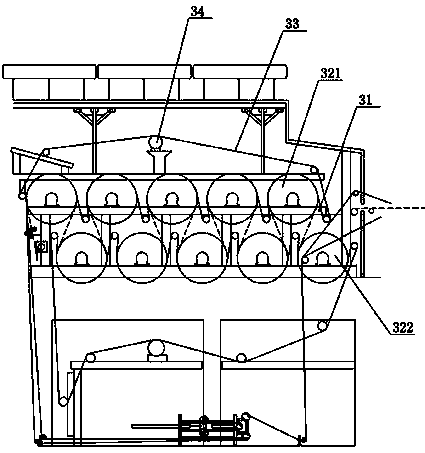

[0099] Pulping equipment I includes hydraulic pulper, high-consistency slag remover, medium-consistency slag remover, single-effect fiber separator, short-fiber pulp separation device, medium-fiber pulp separation device, and long-fiber pulp separation device connected in sequence. The output end of the effective fiber separator is also connected with the slag separator.

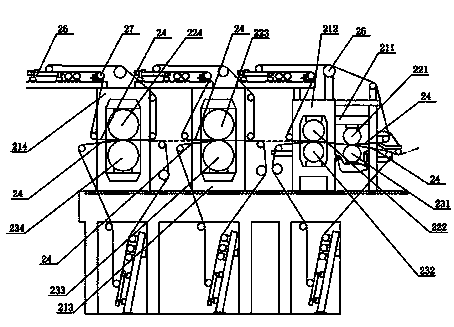

[0100] The fluff pulp separation device includes a first grading screen, a fluff pulp tank, a low-consistency slag remover, and a pulp refiner conne...

Embodiment 2

[0140] A kind of bobbin paper production process, it realizes based on the bobbin paper production system of embodiment 1, comprises the following steps:

[0141] A2. Preparation of pulp y2; B2. Dehydration forming of wire part; C2. Pressing; D2. Drying; E2. Calendering; F2. Roll paper; G2. Preparation of pulp x2; Forming; G2. Pressing; K2. Drying; L2. Calendering; M2. Roll paper.

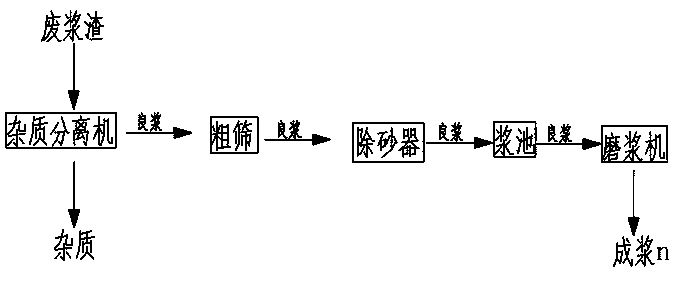

[0142] A2. Preparation into slurry y2

[0143] After the waste cardboard is pulped by a hydraulic pulper, it is successively passed through a high-concentration cleaner and a medium-concentration cleaner to remove pulp residue in the slurry, and then sent to a single-effect fiber separator for fiber separation to separate effective slurry After ya2 and ya2 enter the fiber separator, the fibers are disintegrated by blades and impellers, and then the slurry that passes through the sieve plate under a certain pressure becomes effective slurry. The waste slurry discharged from the single-effect separ...

Embodiment 3-6

[0174] Embodiment 3-6 is a kind of bobbin paper production process respectively, and their difference with embodiment 2 is only that the control parameter in its production process is different, specifically as shown in the table below:

[0175]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Ring pressure index | aaaaa | aaaaa |

| Ring pressure index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com