Bobbin paper production system and corresponding bobbin paper production process

A production system, technology of bobbin paper, applied in the field of papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1 bobbin paper production system

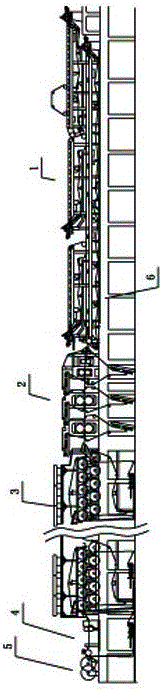

[0095] A bobbin paper production system includes a high-grade bobbin paper production line and a middle-grade bobbin paper production line.

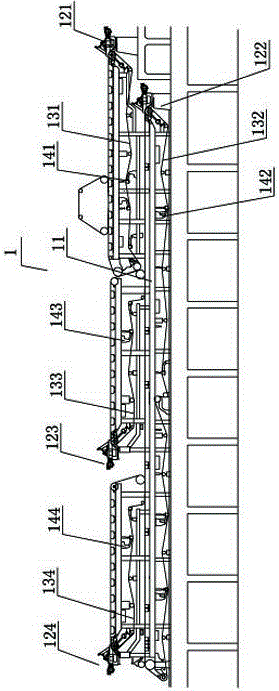

[0096] 1. High-grade bobbin paper production line includes pulping module Ⅰ and papermaking module Ⅰ.

[0097] (1) Pulping Module I

[0098] Pulping module I includes pulping equipment I for manufacturing pulp y made from waste cardboard, such as Figure 6 shown.

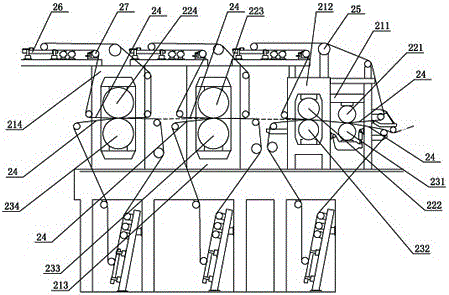

[0099] Pulping equipment I includes hydraulic pulper, high-consistency slag remover, medium-consistency slag remover, single-effect fiber separator, short-fiber pulp separation device, medium-fiber pulp separation device, and long-fiber pulp separation device. The output end of the effective fiber separator is also connected with the slag separator.

[0100] The fluff pulp separation device includes a first grading screen, a fluff pulp tank, a low-consistency slag remover, and a pulp refiner connected in sequence. The m...

Embodiment 2

[0140] A kind of bobbin paper production process, it realizes based on the bobbin paper production system of embodiment 1, comprises the following steps:

[0141] A2. Preparation of pulp y2; B2. Dehydration forming of wire part; C2. Pressing; D2. Drying; E2. Calendering; F2. Roll paper; G2. Preparation of pulp x2; Forming; G2. Pressing; K2. Drying; L2. Calendering; M2. Roll paper.

[0142] A2. Preparation into slurry y2

[0143] After the waste cardboard is pulped by the hydraulic pulper, the pulp residue in the slurry is removed through the high-concentration cleaner and the medium-concentration cleaner in turn, and then sent to the single-effect fiber separator, and the fiber is broken by the blade and the impeller. , and then the slurry that passes through the sieve plate under a certain pressure becomes the effective slurry ya2. The waste slurry discharged from the single-effect separator enters the slag discharge separator. After the waste residue is removed, the remain...

Embodiment 3-7

[0174] Embodiment 3-7 is a kind of bobbin paper production process respectively, and their difference with embodiment 2 is only that the control parameter in its production process is different, specifically as shown in the following table:

[0175]

[0176]

[0177]

[0178]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com