Rolling bearing vibration detection device and analysis method

A kind of rolling bearing and vibration detection technology, applied in the direction of measuring device, vibration test, mechanical bearing test, etc., can solve the problems of difficult to separate influence, difficult to distinguish vibration frequency components, complex frequency components of bearing vibration signal, etc., to achieve accurate response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The rolling bearing vibration detection device and analysis method provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

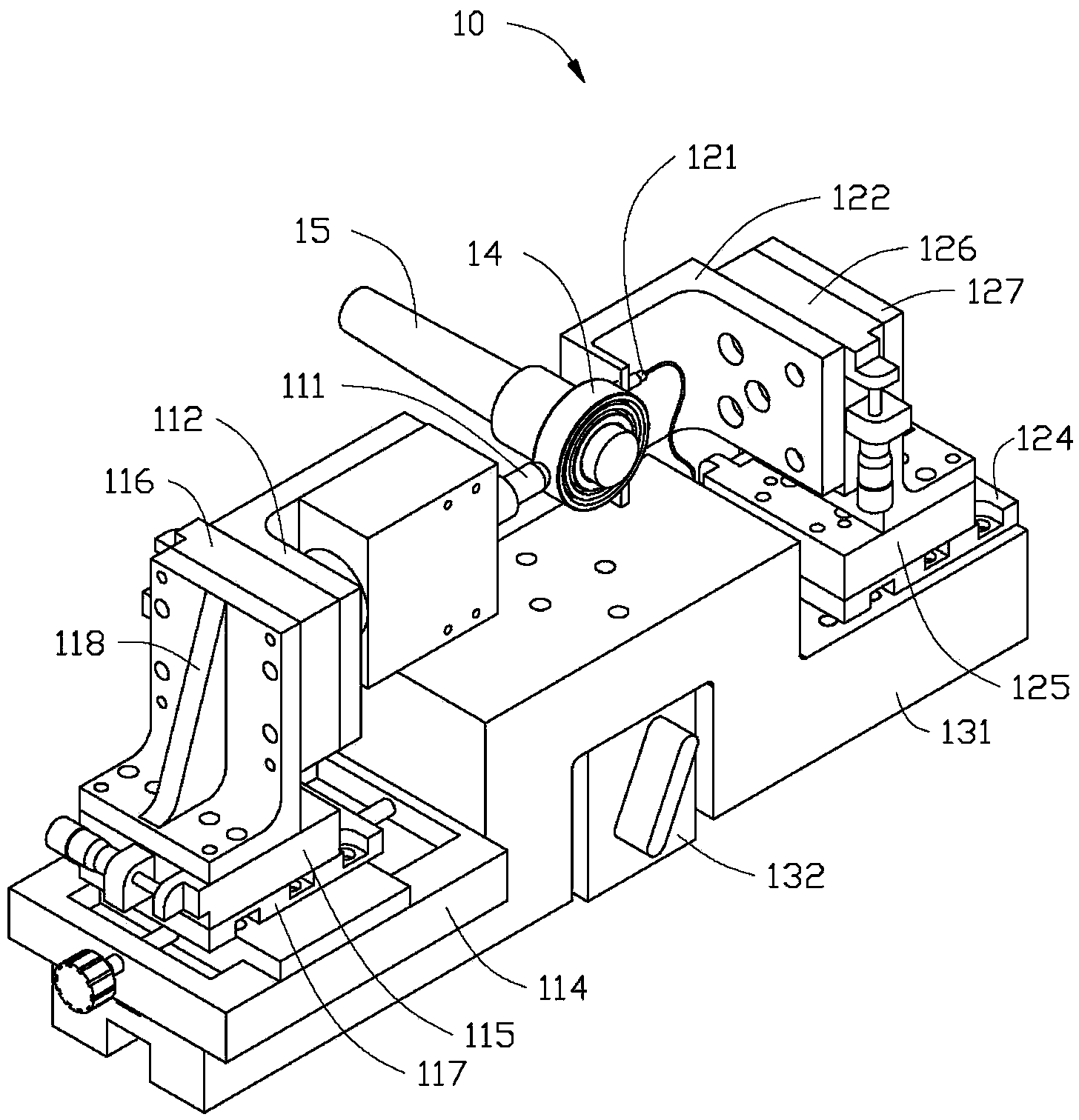

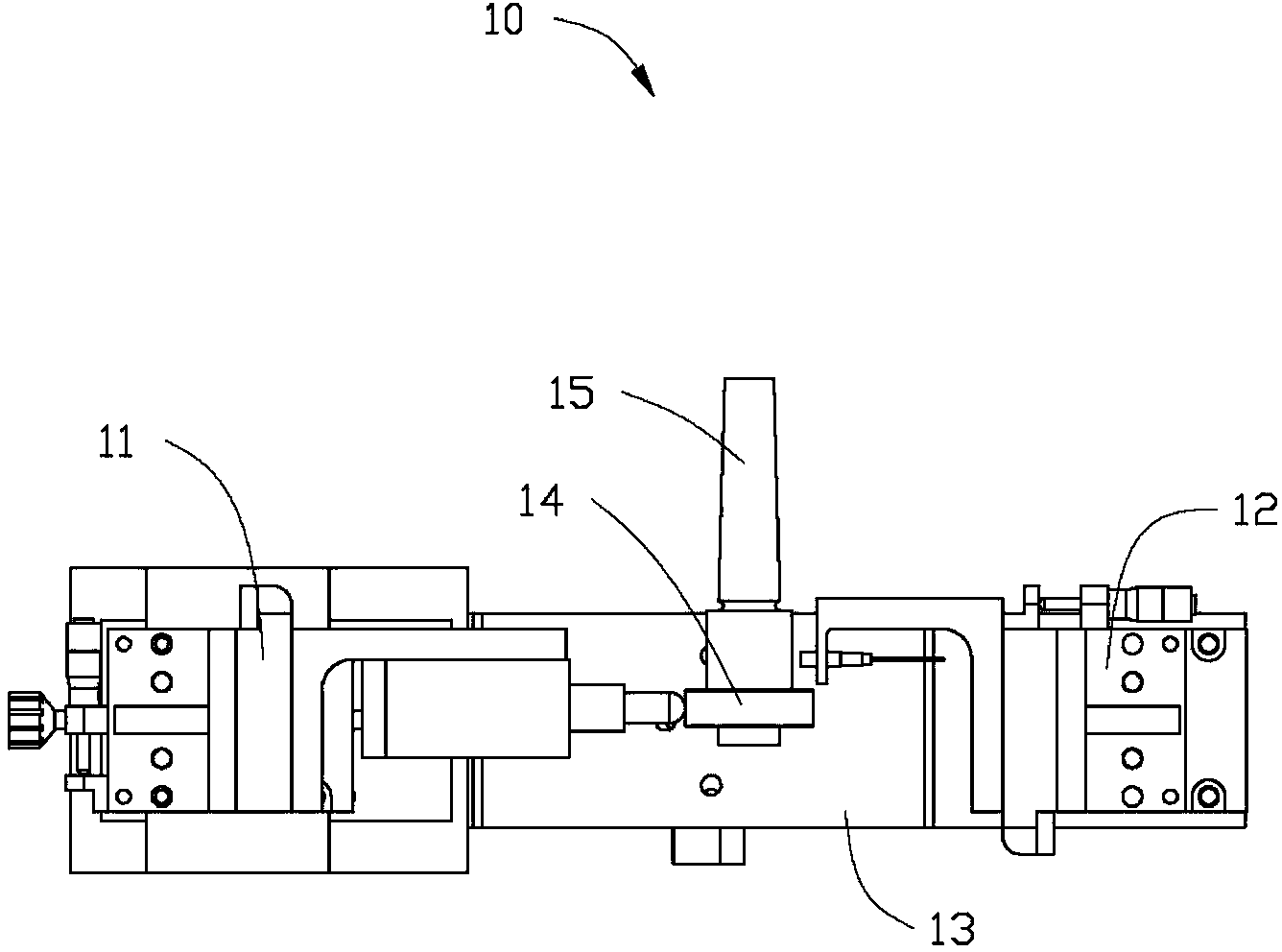

[0023] Please also refer to figure 1 and figure 2 , the embodiment of the present invention provides a rolling bearing vibration detection device 10 . The rolling bearing vibration detection device 10 includes a bearing vibration measurement unit 11, a spindle rotation error measurement unit 12 and a base 13, the bearing vibration measurement unit 11 and the spindle rotation error measurement unit 12 are fixedly installed on the base 13 respectively, and are located at the Measure both sides of the spindle 15 of the rolling bearing 14.

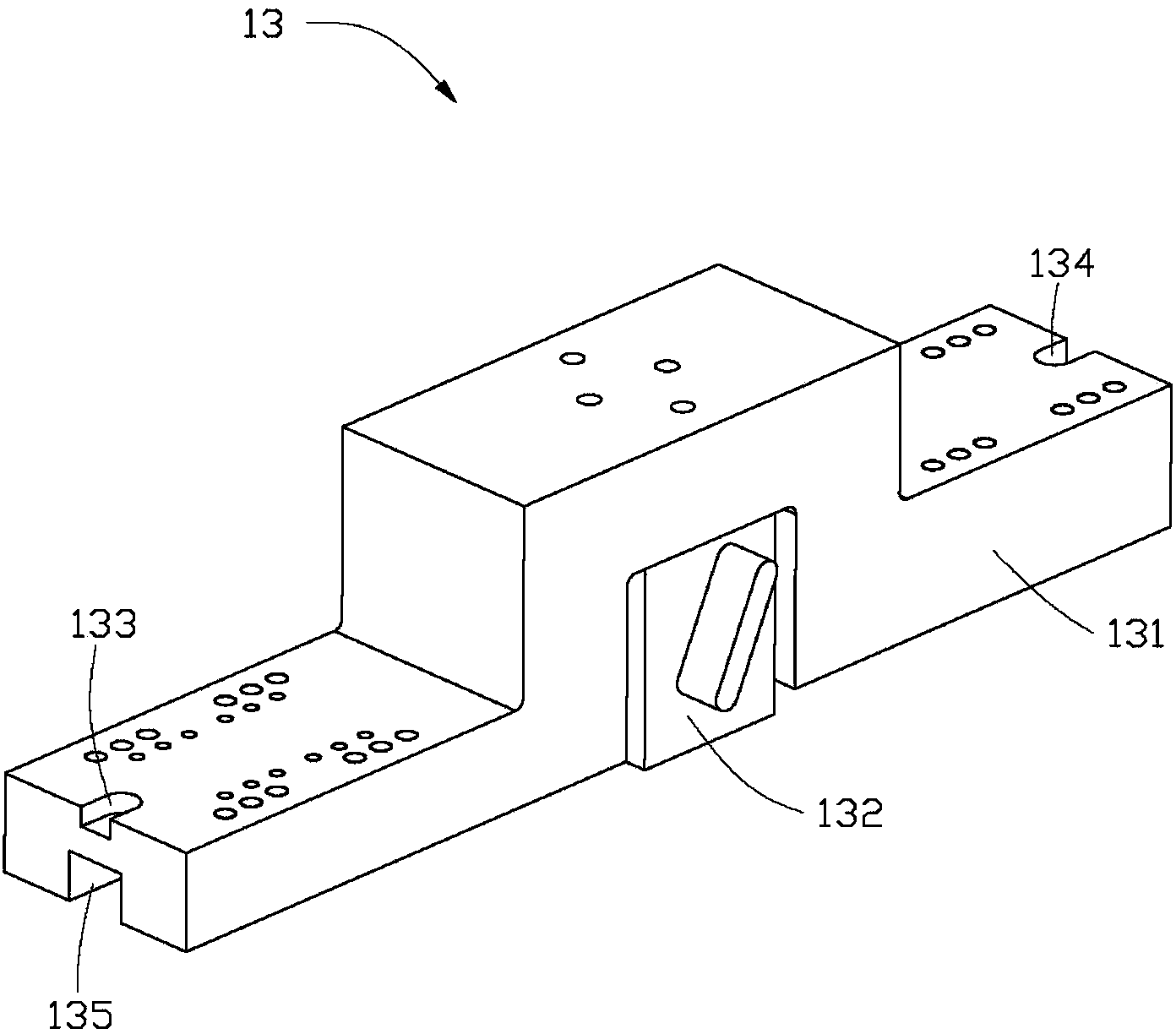

[0024] Please also refer to image 3 , the base 13 includes an arched beam 131 and a magnetic base 132, the arched beam 131 and the magnetic base 132 are connected by bolts, the magnetic base 132 is adsorbed on the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com