Method and device for deodorizing domestic waste

A domestic garbage and rotary kiln technology, applied in the direction of deodorization, disinfection, etc., can solve the problems of potential safety hazards, unsatisfactory deodorization effect, and large labor cost, and achieve energy saving, good effect, and manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

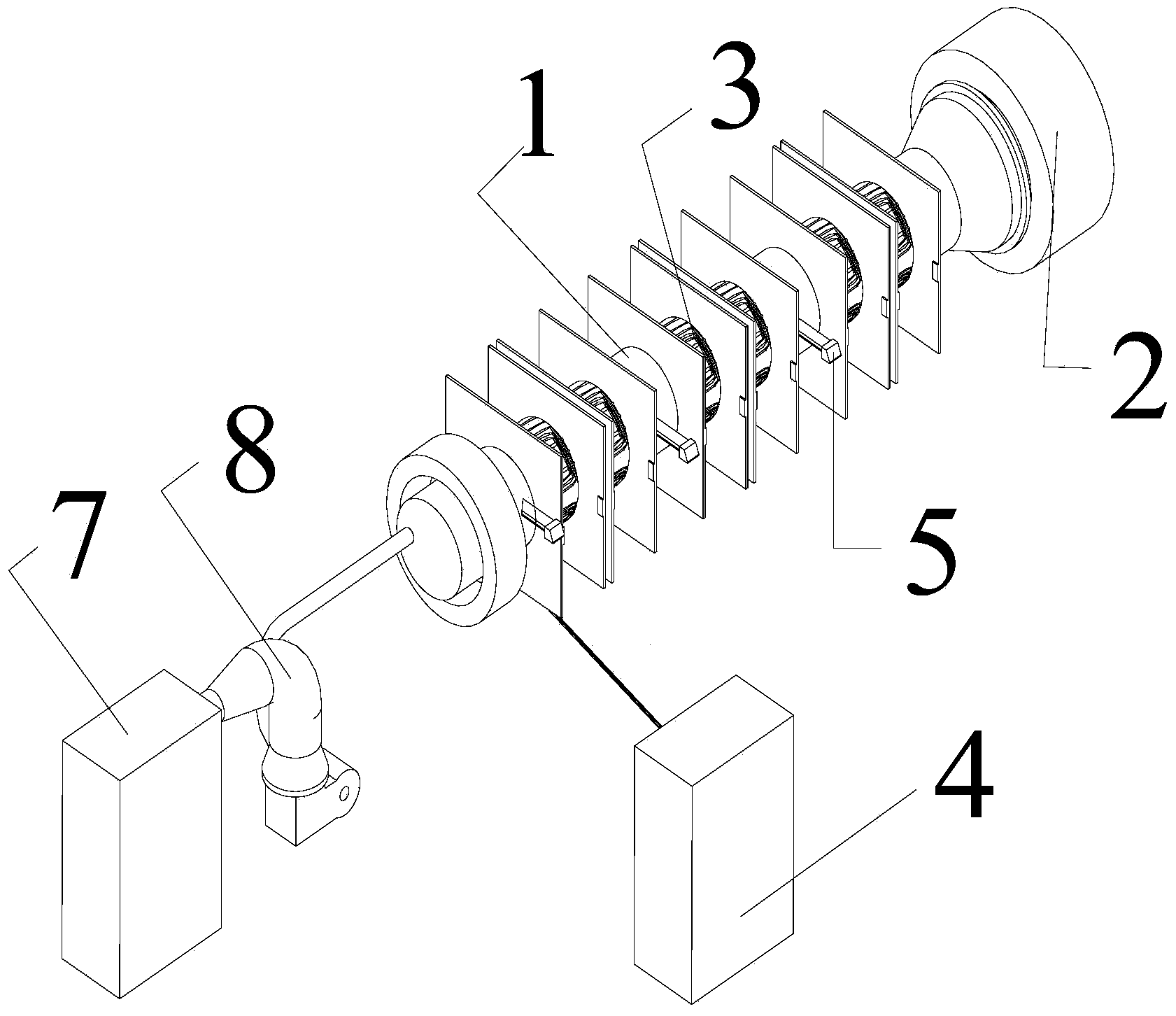

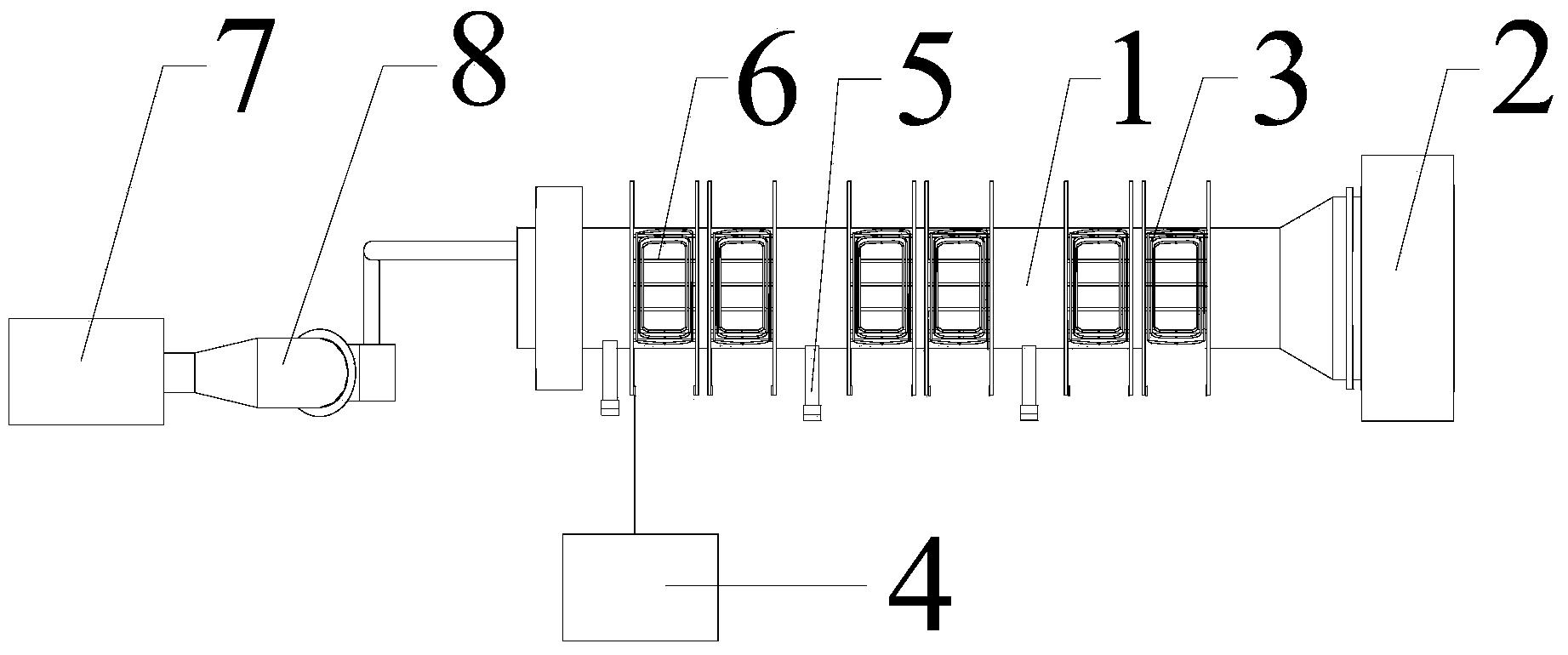

[0046] Such as figure 1 and figure 2 As shown, the rotary kiln 1 is installed horizontally, the installation slope is 4%, the length of the selected rotary kiln is 20m, and the diameter is 3m;

[0047] A non-metallic frame 6 is set along the rotary kiln 1, and cables are wound on the non-metallic frame 6 to form a medium-high frequency coil 3; a refractory material is also arranged between the non-metallic frame and the rotary kiln, and the refractory material is wrapped on the rotary kiln to form a refractory material layer, the thickness of the refractory material layer is 5cm, and the distance between the non-metallic frame and the refractory material layer is 3cm; the length direction of the rotary kiln 1 is uniformly arranged with 3 groups of medium and high frequency coils 3, and each group of medium and high frequency coils 3 includes 2 The middle and high frequency coils 3 are placed, the distance between each group of middle and high frequency coils 3 is 1m, and eac...

Embodiment 2

[0054] The rotary kiln is installed horizontally, the installation slope is 6%, the length of the selected rotary kiln is 40m, and the diameter is 5m;

[0055] A non-metallic frame is set along the rotary kiln, and cables are wound on the non-metallic frame to form a medium-high frequency coil; a refractory material is also arranged between the non-metallic frame and the rotary kiln, and the refractory material is wrapped on the rotary kiln to form a refractory material layer. The thickness of the layer is 8cm, and the distance between the non-metal frame and the refractory layer is 4cm; 8 groups of medium-high frequency coils are evenly arranged in the length direction of the rotary kiln, and each group of medium-high frequency coils includes 2 medium-high frequency coils next to each other. The distance between the medium and high frequency coils in the group is 1m, and each group of medium and high frequency coils is equipped with a temperature control device, and the temper...

Embodiment 3

[0062] The rotary kiln is installed horizontally, the installation slope is 2%, the length of the selected rotary kiln is 6m, and the diameter is 1.5m;

[0063] A non-metallic frame is set along the rotary kiln, and cables are wound on the non-metallic frame to form a medium-high frequency coil; a refractory material is also arranged between the non-metallic frame and the rotary kiln, and the refractory material is wrapped on the rotary kiln to form a refractory material layer. The thickness of the layer is 3cm, and the distance between the non-metallic frame and the refractory layer is 2cm; a set of medium-high frequency coils is uniformly arranged in the length direction of the rotary kiln, and the set of medium-high frequency coils includes two medium-high frequency coils next to each other. Set a temperature control device for the high-frequency coil in the group, and the temperature control device is a wireless transmission type;

[0064] The cables of the medium and high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com