Porous Media Defoamer

A technology of porous media and defoamer, applied in the direction of foam dispersion/prevention, can solve the problems of high equipment requirements, complicated operation and high energy consumption, and achieve the effects of convenient operation, low energy consumption and improved defoaming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

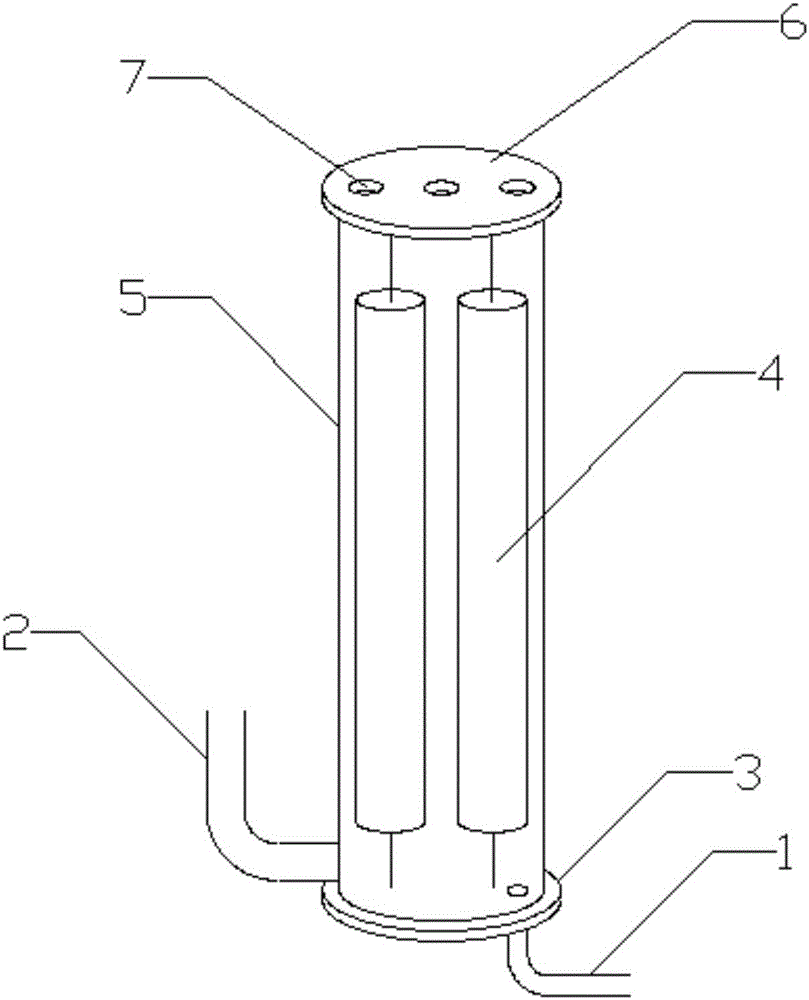

Image

Examples

Embodiment 1

[0022] The material system used is an aqueous solution of sodium lauryl sulfate, the liquid hold-up rate of the formed foam is 1%, the half-life of the foam is 30min (measured by GB / T7462-94) and the superficial flow velocity of the foam is 3.5mm / s, and the foam consists of a foam The inlet pipe enters the defoamer, and the foam flows from bottom to top. The cylinder height-to-diameter ratio of the porous medium defoamer is 1, the porous medium column height-to-diameter ratio is 10, and the number of porous medium columns placed on the unit cross-sectional area of the cylinder is 40 / m 2 , and arranged in an equilateral triangle, the density of polyurethane foam is 45kg / m 3 And the pore diameter is 300um, and the distance from the bottom edge of the foam inlet pipe to the bottom cover is 100mm.

[0023] Under the same system conditions, an empty cylinder without components of the same size is used as the defoamer. After 6 minutes, the foam overflows the defoamer; a stirring ...

Embodiment 2

[0025] The substance used is an aqueous solution of sodium lauryl sulfate, the liquid hold-up rate of the formed foam is 3%, the half-life of the foam is 60min (measured by GB / T7462-94) and the superficial flow velocity of the foam is 7mm / s, and the foam enters from the foam The pipe enters the defoamer, and the foam flows from bottom to top. The cylinder height-to-diameter ratio of the porous medium defoamer is 5, the porous medium column height-to-diameter ratio is 50, and the number of porous medium columns placed on the unit cross-sectional area of the cylinder is 200 / m 2 , and arranged in an equilateral triangle, the density of polyurethane foam is 45kg / m 3 And the pore diameter is 300um, the distance from the bottom edge of the foam inlet pipe to the bottom cover is 200mm.

[0026] Under the same system conditions, an empty cylinder without components of the same size is used as a defoamer. After 5 minutes, the foam overflows the defoamer; a stirring defoamer with a r...

Embodiment 3

[0028] The material system used is sodium lauryl sulfate aqueous solution, the liquid hold-up rate of the formed foam is 5%, the half-life of the foam is 120min (measured by GB / T7462-94) and the superficial flow velocity of the foam is 10mm / s, and the foam enters from the foam The pipe enters the defoamer, and the foam flows from bottom to top. The cylinder height-to-diameter ratio of the porous medium defoamer is 10, the porous medium column height-to-diameter ratio is 80, and the number of porous medium columns placed on the unit cross-sectional area of the cylinder is 1200 / m 2 , and arranged in an equilateral triangle, the density of polyurethane foam is 45kg / m 3 And the pore diameter is 300um, the distance from the bottom edge of the foam inlet pipe to the bottom cover is 300mm.

[0029] Under the same system conditions, an empty cylinder without components of the same size is used as the defoamer. After 4 minutes, the foam overflows the defoamer; a stirring defoamer wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com