An acid gas treatment system and treatment method based on ammonia desulfurization

A treatment system, ammonia desulfurization technology, applied in the field of acid gas treatment, can solve the problems of increasing energy consumption and investment of ammonium sulfate crystallization system, affecting the concentration of ammonium sulfate solution, and high water content of Claus tail gas, so as to achieve effective utilization of reaction emissions The effect of heat, low equipment material requirements, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

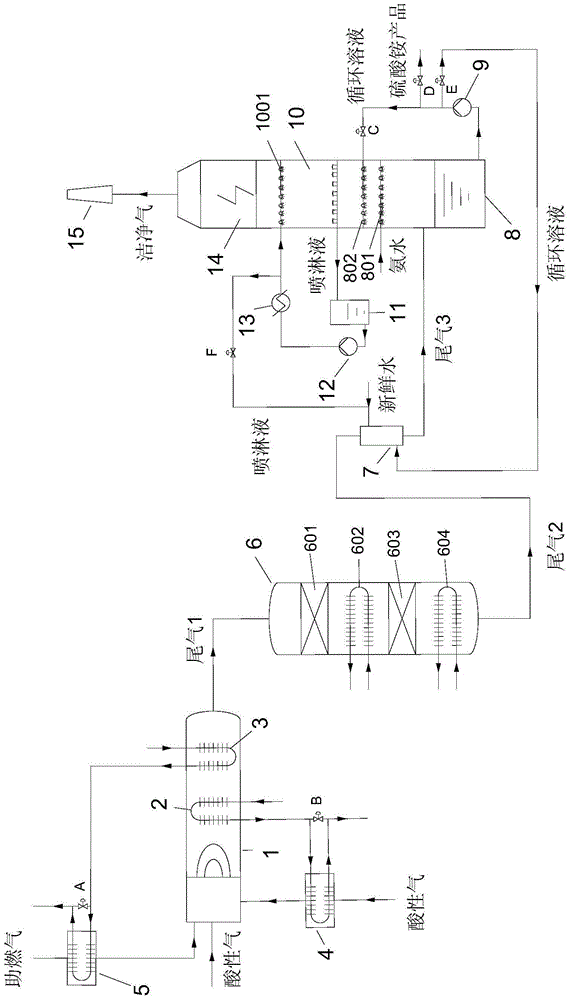

[0047] One aspect of the present invention provides an acid gas treatment system based on ammonia desulfurization, comprising the following treatment units connected in sequence:

[0048] The acid gas incineration unit is used to incinerate the acid gas to be treated to convert the sulfur contained in it into SO 2 ;

[0049] Incineration tail gas oxidation unit, used for SO in the tail gas of acid gas incineration unit 2 Oxidation to SO 3 ;

[0050] The quenching unit is used to cool the tail gas of the incineration tail gas oxidation unit;

[0051] Ammonium sulphate production unit, used to remove SO from the tail gas of the quenching unit 3 React with ammonia to form ammonium sulfate and discharge;

[0052] cooling dehydration unit for cooling the tail gas of the ammonium sulfate unit; and

[0053] The tail gas demisting unit is used to discharge the tail gas of the cooling dehydration unit after demisting.

[0054] When the acid gas treatment system of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com