High-pressure pulverizer

A pulverizer and high-pressure technology, which is applied in the field of high-pressure pulverizers, can solve problems such as poor dust removal effect, low grinding pressure, and small crushing hardness range, and achieve durable, stable and reliable, small footprint, and uniform fineness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

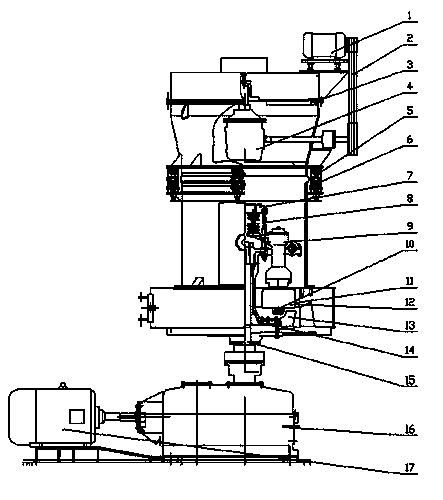

[0013] refer to figure 1 , the specific embodiment adopts the following technical solutions: high-pressure mill, including the first motor 1, V-belt 2, blade 3, oil pool 4, soft connection industrial cloth 5, spring 6, spring seat 7, pull rod 8, grinding roller Chamber 9, grinding roller shaft 10, grinding ring 11, grinding roller 12, blade 13, blade disk 14, main shaft 15, speed reducer 16 and second motor 17, second motor 17 is connected with main shaft 15 through speed reducer 16, The main shaft 15 is provided with a shovel disc 14, the shovel 13 is provided with a shovel 13, the grinding roller chamber 9 is arranged above the shovel 13, the grinding roller shaft 10 is arranged in the grinding roller chamber 9, and the grinding roller shaft 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com