Descaling device for shafts

A descaling and deoxidizing technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of human injury, product quality defects, incomplete removal of surface oxide scale, etc. The effect of avoiding injuries, reducing the risk of non-conforming quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

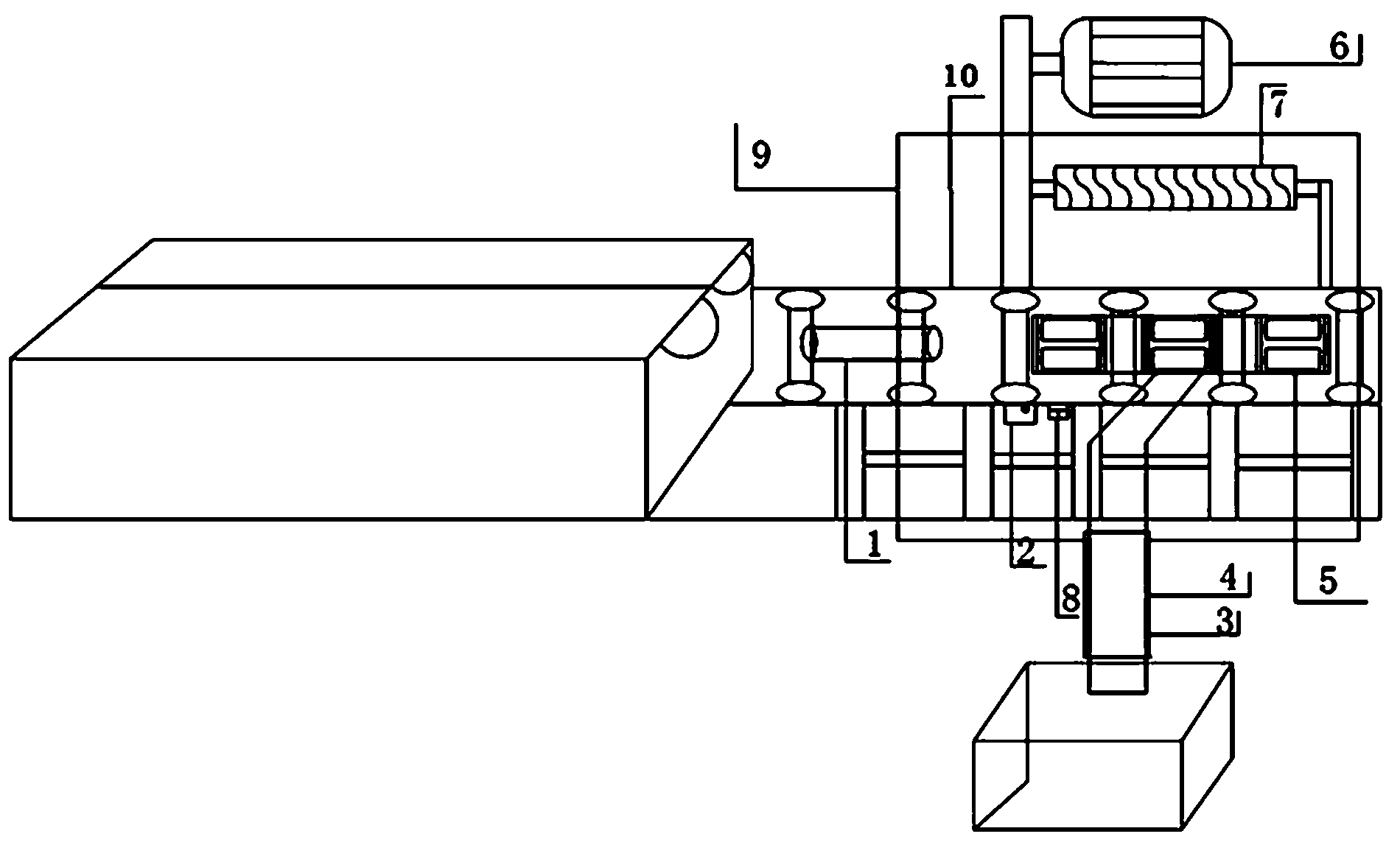

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] like figure 1 as shown, one A shaft type descaling device, which is provided with an inductor 2, a cylinder 3, a lifting shaft 4, an auxiliary descaling shaft and a tray 5, a motor 6, a main descaling shaft 7, a timer 8, a protective cover 9 and Track 10.

[0010] The workpiece 1 comes out of the intermediate frequency heating furnace and enters the track 10 for processing. The sensor 2 senses the workpiece 1 and sends out a signal, so that the workpiece 1 stops at the middle position of the auxiliary descaling shaft and the pallet 5, and the cylinder 3 lifts the lifting shaft 4 to drive it. The auxiliary descaling shaft with the workpiece 1 and the pallet 5 move up. After the ascent, the timer 8 starts counting, and the motor 6 drives the main descaling shaft 7 to rotate 360° to remove the oxide skin on the surface of the workpiece 1. Timer 8 stops after cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com