Protrusion pulling die

A technology of molds and mold bases, applied in forming tools, manufacturing tools, presses, etc., can solve problems such as product deformation, product distortion, and poor product quality, and achieve the effects of reducing costs, simple structure, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

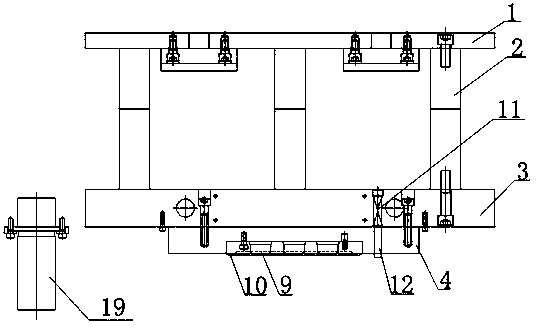

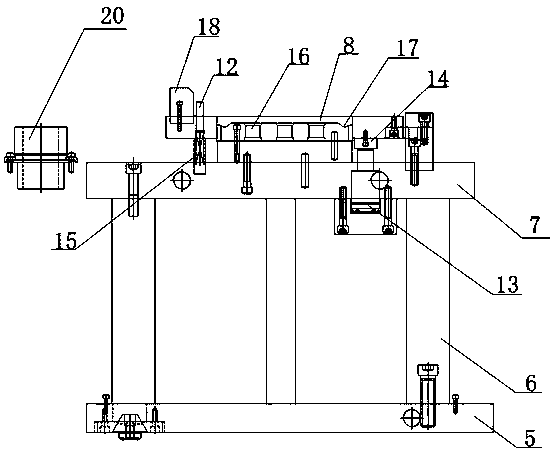

[0013] like Figure 1~2 Shown, a kind of pull-convex mold comprises upper mold and lower mold, and upper mold comprises the upper support plate 1 that connects from top to bottom, upper spacer 2, upper mold base 3 and upper template 4, and lower mold includes from bottom to top Connected lower supporting plate 5, lower cushion block 6, lower mold base 7 and lower stripping plate 8, the upper template 4 is fixedly equipped with a pull bump 9, and both sides of the pull bump 9 are provided with positioning convex hulls 10, and the upper mold The base 3 is equipped with a spring I11, the lower end of the spring I11 is connected to a T-shaped ejector pin 12, the T-shaped ejector pin 12 passes through the upper mold plate 4, and a nitrogen spring 13 is fixedly installed on one side of the lower mold base 7, and the nitrogen spring 13 is connected to an input block 14 , the input block 14 is fixed on the lower stripping plate 8, and the other side of the lower mold base 7 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com