Tire pressure sensor configured with helical antenna

A helical antenna and tire pressure technology, which is applied in tire measurement, tire parts, transportation and packaging, etc., can solve the problems that affect the accuracy and distance of wireless signal transmission, the large space occupied by the PCB board antenna, and the interference of antenna transmission quality, etc. , to achieve the effects of small footprint, improved accuracy, and improved emission distance and wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

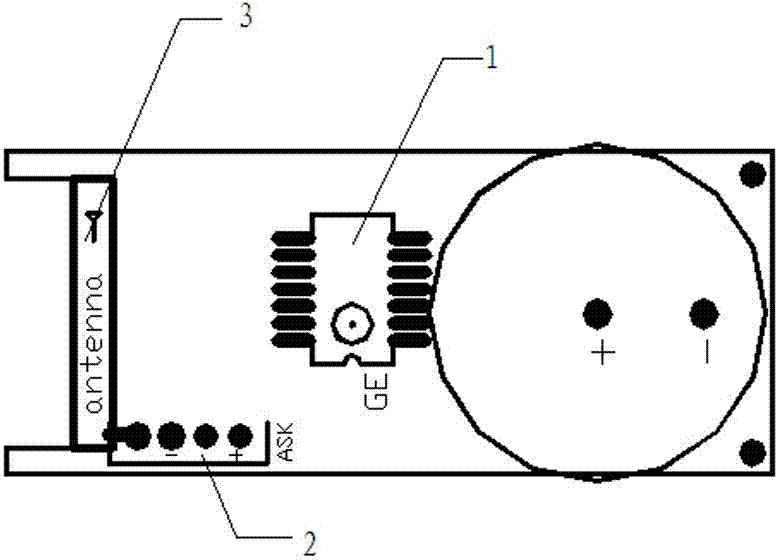

[0015] Embodiment 1: This embodiment provides a tire pressure sensor with a helical antenna, and its structural diagram is as follows figure 1 As shown, it includes a data collector 1, a wireless transmitter 2 and an antenna 3 welded on the PCB, the data sending port of the data collector 1 is connected with the data receiving port of the wireless transmitter 2, and the wireless sending The data transmission port of the device 2 is connected with the antenna 3.

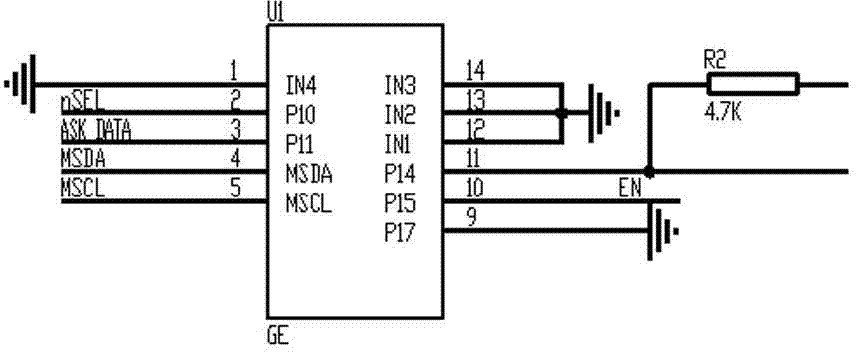

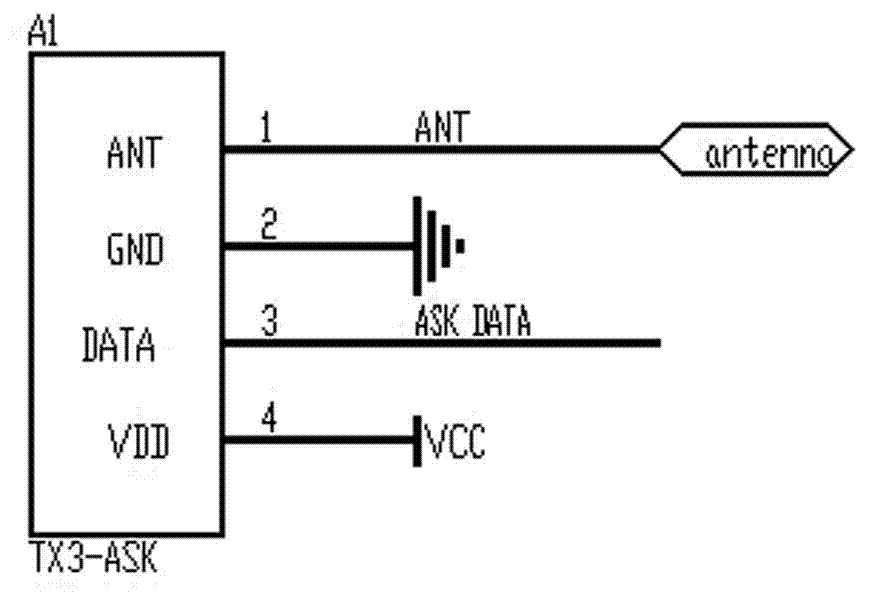

[0016] The circuit diagram of data collector 1 is as follows figure 2 As shown, the chip GE1769 is included, and the chip GE1769 is the main data acquisition component to complete the acquisition of temperature, pressure, acceleration and other data. The circuit diagram of the wireless transmitter 2 is as follows image 3 As shown, the chip TX3-ASK is included, and the chip TX3-ASK is the main data transmission component to realize the wireless transmission of data. The data sending pin P11 of the chip GE1769 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com