DC power supply system and method of trolley locomotive of underground mine

A technology for power supply systems and electric locomotives, applied in power lines, vehicle components, transportation and packaging, etc., can solve problems such as automatic control system misoperation, small automatic system operating current, and life-threatening electric shock for workers to improve safety, The effect of preventing electric shock risk and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

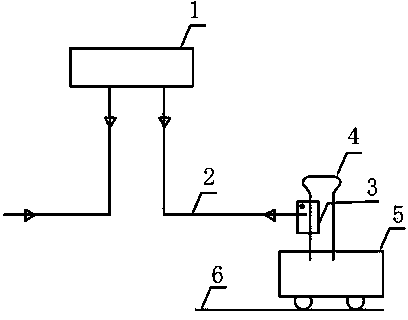

[0036] When the electric locomotive enters the roadway along the main road, the driver pulls down the pantograph of the electric locomotive, and connects the special power supply flexible cable and soft steel wire rope on the side of the roadway to the electric locomotive, and the electric locomotive takes power from the insulated trolley line. The driver drives the electric locomotive according to the normal driving method, and the electric locomotive automatically pulls the flexible cable to run back and forth. When the electric locomotive returns to the starting point and walks into the main transport road, the driver removes the special power supply flexible cable and reuses the pantograph of the electric locomotive itself to take power from the upper wire. The insulated trolley line of the power supply is in the state of insulation protection and no exposure, realizing full-length safe power supply, and there is no risk of electric shock.

[0037] The insulated trolley li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com