Side guard panel subassembly of an automobile engine compartment

A technology for engine compartment and side shields, which is applied to the superstructure sub-assembly, vehicle components, superstructure and other directions, can solve the problems of heavy weight and complex structure, and achieve the effect of improving the torsional rigidity of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

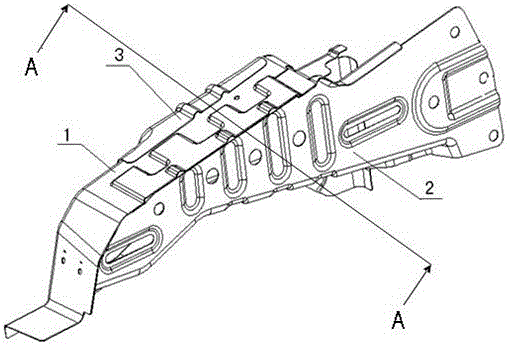

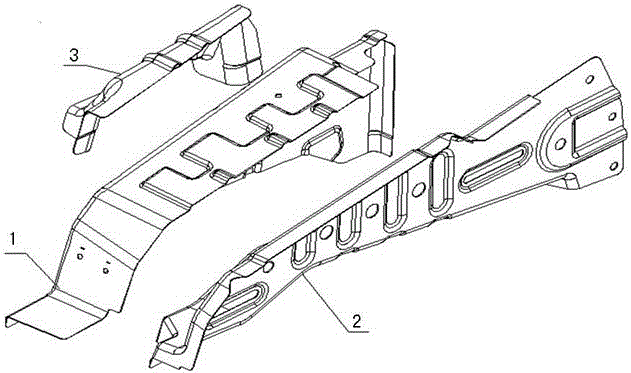

[0018] see figure 1 , figure 2 and image 3 An automobile engine compartment side guard sub-assembly shown includes an engine compartment side guard 1, and its structural features are: one side guard plate reinforcement 2 is fixedly connected to the right side of the engine compartment side guard, and a The shock absorber bracket reinforcement 3 is fixedly connected to the left side of the side guard plate of the engine compartment.

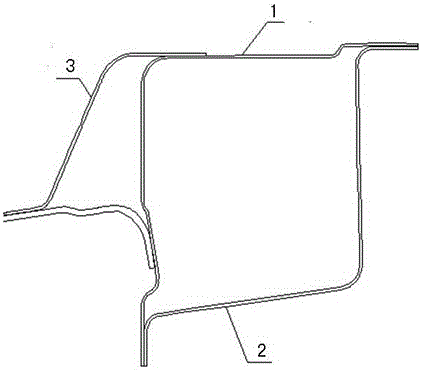

[0019] Further, the engine compartment side guard plate 1 is a sheet metal part with an inverted "L" shape in cross section; a first welding surface 11 is provided on the upper part of the engine compartment side guard plate, and a second welding surface is provided on the front part 12 and the third welding surface 13, the left side is provided with the fourth welding surface 14;

[0020] The side guard reinforcement 2 is a sheet me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com