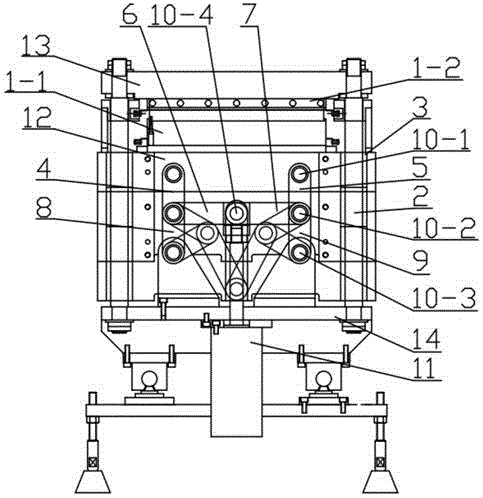

Multi-group connecting rod transverse forming punching mechanism and operation method for blister packaging machine

A connecting rod mechanism and blanking technology, which is applied in packaging and other directions, can solve the problems of equipment impact, large up and down moving distance, and the gas-liquid pressurization system is not suitable for blanking methods, etc., to achieve compact structure, long service life, and improved Efficiency and applicability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0064] Next, an application example of the present invention is described. In this example, the above-mentioned multi-group connecting rod transverse forming and punching mechanism for a blister packaging machine of the present invention is applied in the transverse cutting process of the packaging material of the blister packaging machine.

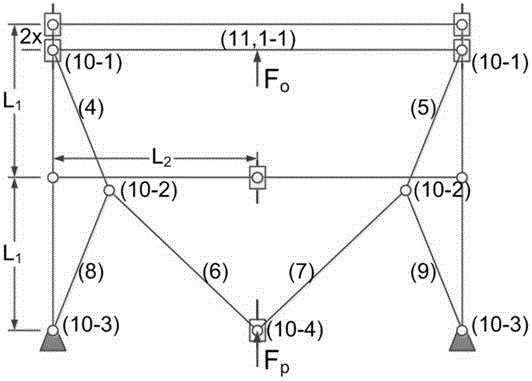

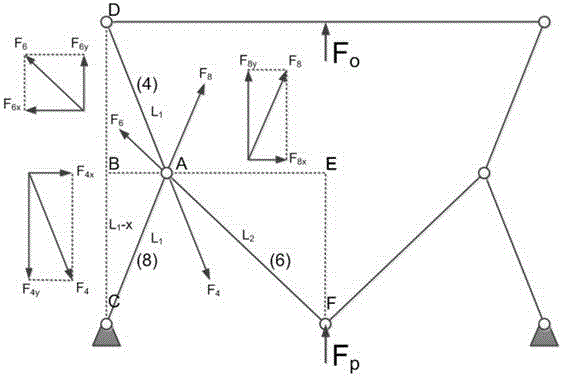

[0065] In this example, the diameter of the driving cylinder 11 is 100mm, the lifting stroke is 175mm, the lifting speed is about 0.175m / s, the air pressure is 0.6MPa, and the thrust is 4712N. The length of drive link 4, 5 is 90mm, the length of rocker 8, 9 is 90mm, and the length of intermediate link 6, 7 is 145mm. The driving links 4, 5 and the rocking bars 8, 9 are arranged symmetrically with a distance of 290mm. The lifting stroke of the die is 90mm, which meets the equipment packaging requirements. At this time, the ratio Fp / Fo of the punching force of the punching actuator to the thrust of the driving cylinder (11) is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com