Negative pressure feeding device for dry method granulator

A dry granulation and negative pressure technology, which is applied in packaging, conveyors, transportation and packaging, etc., can solve the problems of increasing void ratio, affecting feeding efficiency, and paralyzing feeding work, and achieve the effect of improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

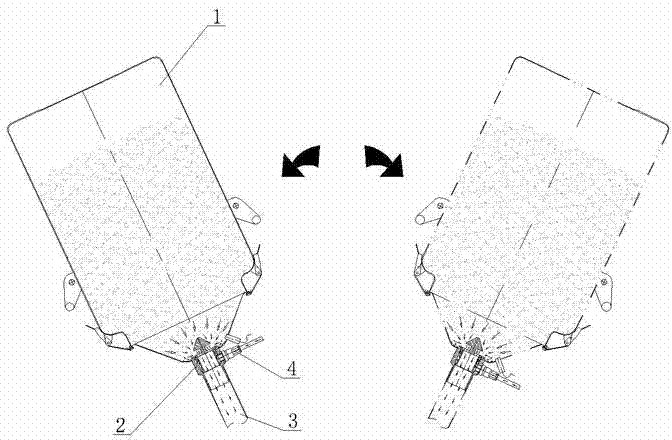

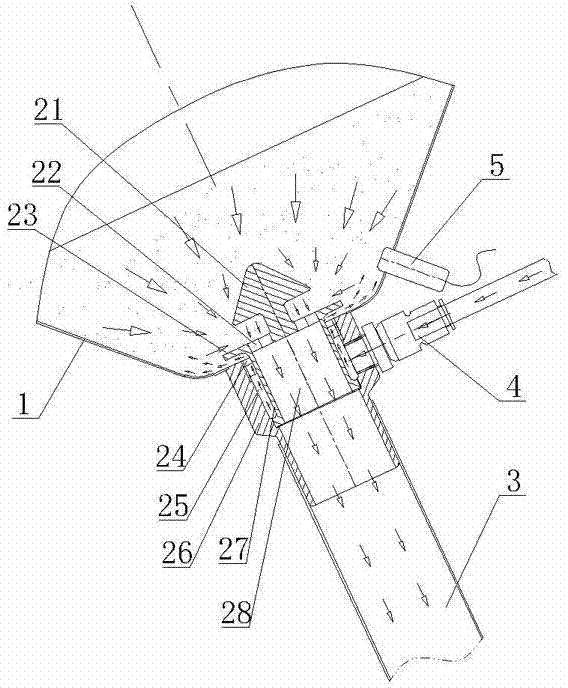

[0014] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details of the embodiments will be further described below in conjunction with the accompanying drawings.

[0015] As shown in the figure, the dry granulator negative pressure feeding device of the present invention includes a storage tank 1, which has a closed space inside, and the bottom of the storage tank 1 is in the shape of a cone, and the storage tank 1 The bottom of the bucket is provided with a connecting part 2 connecting the powder output 3; the connecting part 2 includes an external connecting pipe 26, an internal connecting pipe 27, a powder retaining plate 23 and a powder retaining cover 21, and the external connecting pipe 26 is fixed at the bottom of the barrel outside the storage barrel 1 Installation, the inner connecting pipe 27, the powder retaining plate 23 and the powder retaining cover 21 are integrally structured, the inner connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com