Neutral borosilicate glass and application thereof

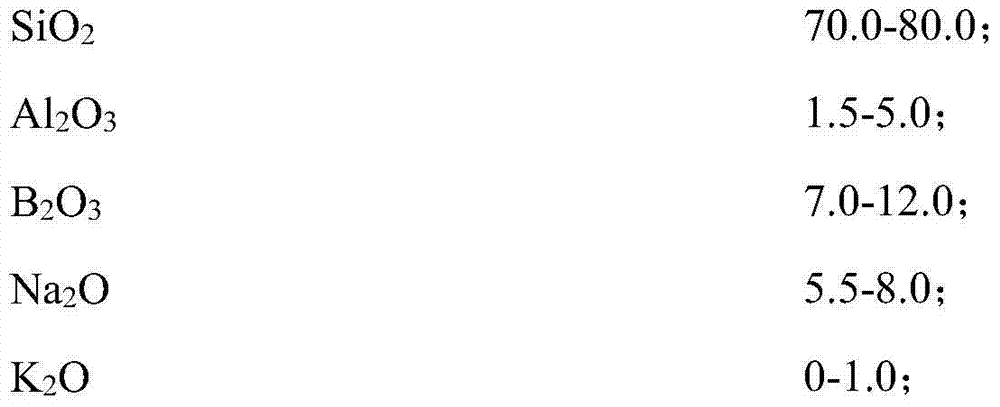

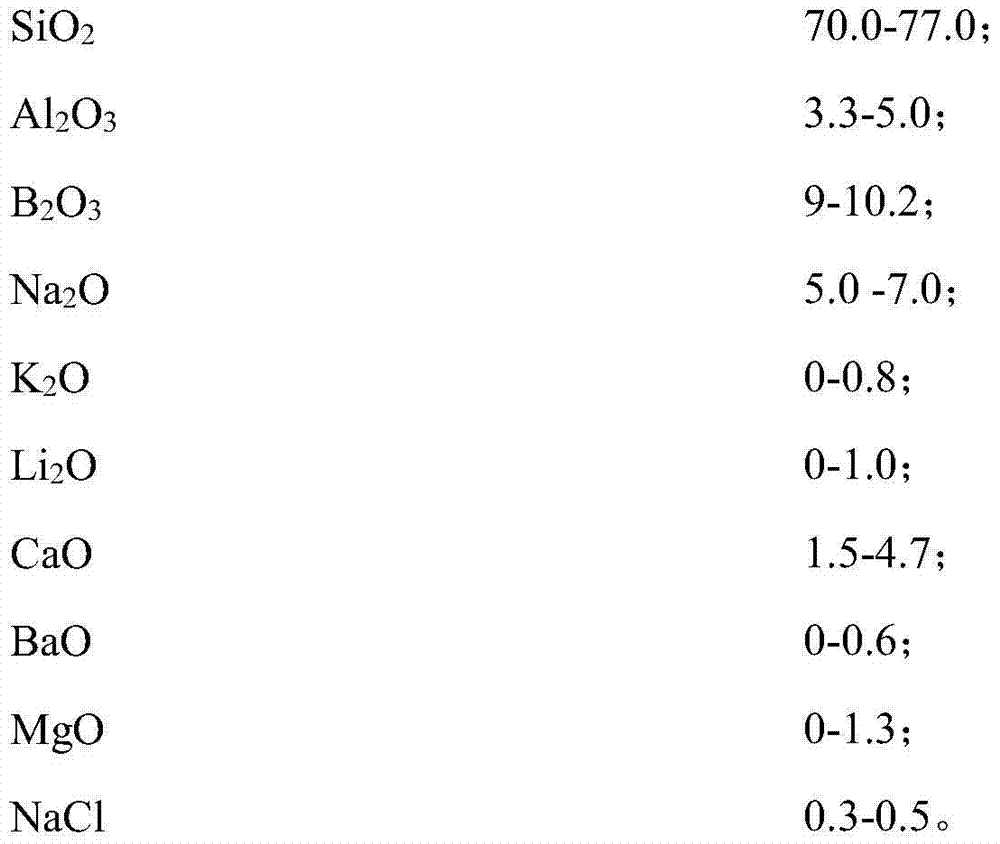

A technology of neutral borosilicate glass and its application, which is applied to the types of packaging items, special packaging objects, medical containers, etc., and can solve the problems that cannot meet the performance requirements of pharmaceutical neutral borosilicate glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] What is described below is the preferred implementation of the present invention, and the protection of the present invention is not limited to the following preferred implementation. It should be pointed out that for those skilled in the art, some modifications and improvements made on the basis of this inventive concept all belong to the protection scope of the present invention. The raw materials used in the examples are all commercially available.

Embodiment

[0023] According to the formula in Table 1, the glass raw materials with a total weight of 300g were accurately weighed and mixed evenly, and the evenly mixed batch was poured into an alumina crucible, and placed in a high-temperature furnace from room temperature to 1650°C at a heating rate of 5°C / min, clarification time is 4 hours, then take out the crucible, pour the glass liquid into the preheated graphite mold, after forming, put the sample into the annealing furnace, the annealing temperature is 560°C±20°C, keep warm The time is half an hour. Cut or grind the glass blocks into blocks, strips, flakes, granules or powder samples of the size specified in YBB00022005-2, the size of the sample required for the 98°C water resistance test is 300μm-500μm, and the required size for the 121°C water resistance test The size of the sample is 600μm-1000μm, and the total surface area of the sample required for the acid resistance test is 100±10cm 2 , the total surface area of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com