Method utilizing tailing sand to carry out sand gradation improvement

A technology of tailings sand and grading is applied in the field of sand grading improvement and sand grading improvement by using tailings sand, which can solve the problems of polluting the environment and the land occupied by tailings, achieve good construction performance, reduce environmental damage, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

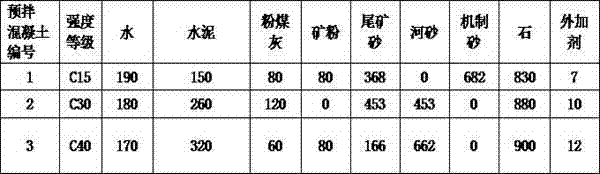

[0028] In Example 2, a is 0.5, b is 0.5, a+b=1, and the fineness modulus of the mixed sand is 2.7, between 2.3 and 3.0. The mixed sand of Example 2 uses the above 50 % Iron tailing sand and 50% river sand and machine-made sand need to be fully mixed.

Embodiment 3

[0029] In Example 3, a is 0.2, b is 0.8, a+b=1, and the fineness modulus of the mixed sand is 2.8, between 2.3 and 3.0. The mixed sand of Example 3 uses the above 20 % Gold mine tailings sand and 80% river sand are fully mixed.

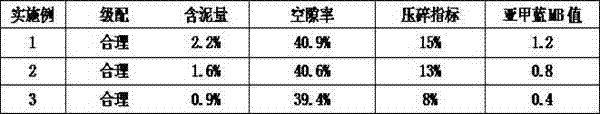

[0030] For the main parameters of the mixed sand in Examples 1-3, see Table 2

[0031]

[0032] The main parameters of mixed sand are tested using JGJ52-2006 "Standard for Quality and Inspection Methods of Sand and Stone for Common Concrete".

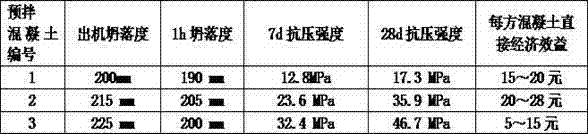

[0033] The ready-mixed concrete prepared by using the mixed sand of the above Examples 1-3, the main data is shown in Table 3

[0034] table 3

[0035]

[0036] According to specific embodiments, the working performance, mechanical performance, and durability of the ready-mixed concrete disclosed in the present invention are tested. The test method of work performance is tested in accordance with GB / T50080-2002 "Standard for Test Methods for the Performance of Ordinary Concrete Mixtures", and the testing index requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com