Water-based binder for automotive interior parts and preparation method of water-based binder

An automotive interior parts, water-based technology, applied in the direction of adhesives, etc., can solve the problems of insufficient bonding strength, irritating odor, poor temperature resistance, etc., and achieve good adhesion, high peel strength, non-corrosiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0046] A preparation method of water-based adhesive for automotive interior parts, characterized in that, comprising the following steps:

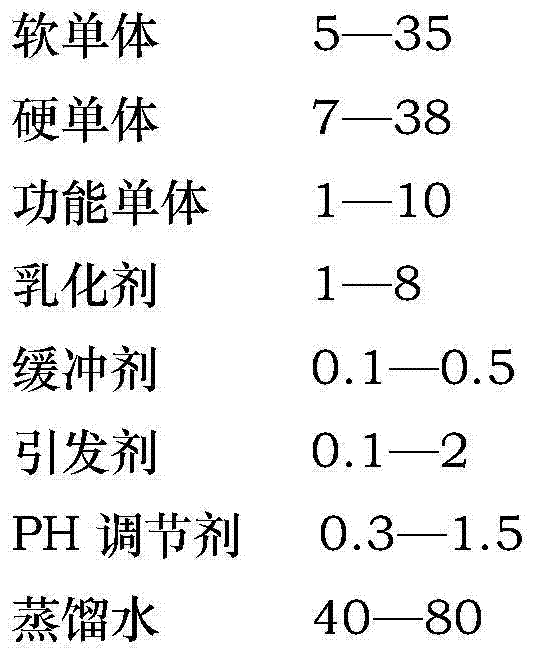

[0047] a. Take 36-72 parts of distillation, 4.6-32 parts of soft monomers, 6.5-35 parts of hard monomers, 0.5-5 parts of functional monomers and 0.9-5 parts of emulsifiers according to the mass parts, and then put them into the mixture with stirring Pre-emulsification is carried out in the flask of the device, and the mixture is prepared for use;

[0048] b. Add 4-8 parts of distilled water, 0.4-3 parts of soft monomers, 0.5-3 parts of hard monomers, and 0.5-5 parts of functional monomers to the four-necked flask equipped with agitator, thermometer, reflux condenser and feeding device parts, 0.1-3 parts of emulsifier and 0.1-0.5 parts of buffering agent, heated with water bath, when the temperature rises to 70 degrees, add 0.01-0.4 parts of initiator to initiate the reaction to obtain the latex particles required for the reaction;

[0049...

Example Embodiment

[0051] Example 1

[0052] a. Take 72ml of distilled water, 4.6g of ethyl acrylate, 6.5g of methyl methacrylate, 3.8g of hydroxyethyl acrylate, emulsifier by nonylphenol polyoxyethylene ether: sodium lauryl sulfate: N-dodecane dimethylamine=1:0.5:0.5 to prepare 2.6g of composite emulsifier, and sequentially added to a flask equipped with a stirrer for pre-emulsification to prepare a mixture for later use;

[0053] b. Add 8ml distilled water, 0.5g ethyl acrylate, 0.7g methyl methacrylate, 0.5g hydroxyethyl acrylate, 0.3g compound emulsification to the four-necked flask equipped with a stirrer, thermometer, reflux condenser and feeding device agent and 0.1g sodium hydrogen phosphate, heated in a water bath, when the temperature rose to 70 degrees, 0.01g potassium persulfate was added to initiate the reaction to obtain the latex seeds required for the reaction;

[0054] c, then slowly drip the mixture prepared through pre-emulsification and the remaining 0.09g potassium persulfat...

Example Embodiment

[0056] Example 2

[0057] a Take 59ml of distilled water, 5g of ethyl acrylate, 5g of butyl acrylate, 7.5g of methyl acrylate, 7.5g of styrene, 2.35g of acrylic acid, and emulsifier according to nonylphenol polyoxyethylene ether: sodium dodecylbenzenesulfonate: N-dodecyl dimethylamine=1.6:0.8:0.8 is made into 2g of composite emulsifier, which is sequentially added to a flask equipped with a stirrer for pre-emulsification, and a mixture is prepared for subsequent use;

[0058] b. Add 6.7ml distilled water, 0.55g ethyl acrylate, 0.55g butyl acrylate, 0.85g methyl acrylate, 0.85g styrene, 0.5 g acrylic acid, 0.15g composite emulsifier and 0.2g sodium bicarbonate, heated in a water bath, when the temperature rose to 70 degrees, 0.05g ammonium persulfate was added to initiate the reaction to obtain the latex seeds required for the reaction;

[0059] c, then, slowly dropwise add the mixture prepared by pre-emulsification and the remaining 0.45g of ammonium persulfate, the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com