Testing device and testing method for horizontal well subsection well completion inflow

A testing device and technology for horizontal wells, which are applied to wellbore/well components, measurement, earth-moving drilling, etc., can solve the problems such as the inflow testing device and testing method for segmented completion of horizontal wells that have not yet been seen, and achieve simple and reliable devices. Good performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

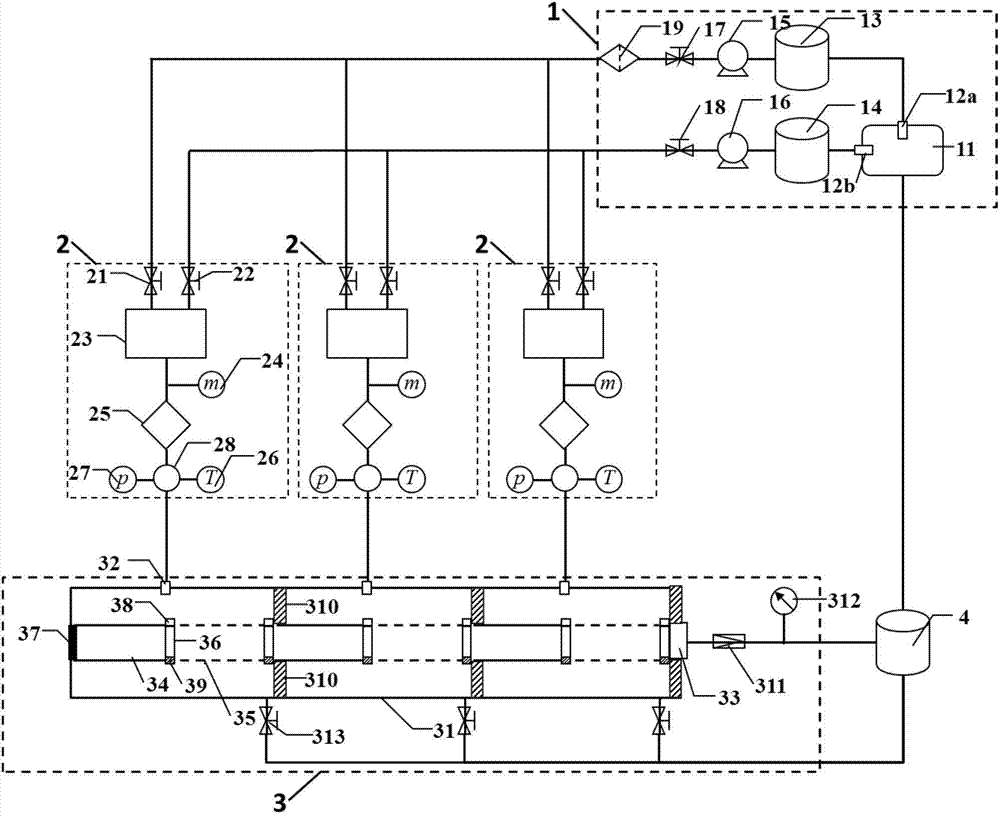

[0015] like figure 1 As shown in the figure, the horizontal well staged completion inflow test device has three stages, including: oil-water separation pumping system 1, oil-water mixed inflow system 2, horizontal well staged completion simulation wellbore system 3, deceleration buffer tank 4 ; Oil-water separation and pumping system 1 is used for pumping and separation of oil-water two-phase fluid. Three sets of oil-water mixed inflow systems 2 are connected in parallel through oil-water external pipelines. The inflow holes 32 of the wellbore system 3 are connected to each other; the oil-water mixed inflow system 2 realizes the fluid environment simulation of segmented inflow, and the horizontal well segmented completion simulation wellbore system 3 is used to simulate the fluid flow state and fluid parameter changes in the horizontal wellbore of segmented well completion. The simulation wellbore system 3 of the horizontal well staged completion is connected to the inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com