Pressure-relief type automatic multi-buffered reset explosion door

A kind of explosion-proof door, automatic technology, used in mining equipment, mining equipment, earth-moving drilling and other directions, can solve the problems of blocking, time-consuming, increase the labor intensity of workers, etc., to achieve synchronous opening and closing, locking operation is simple and easy Effects on and off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

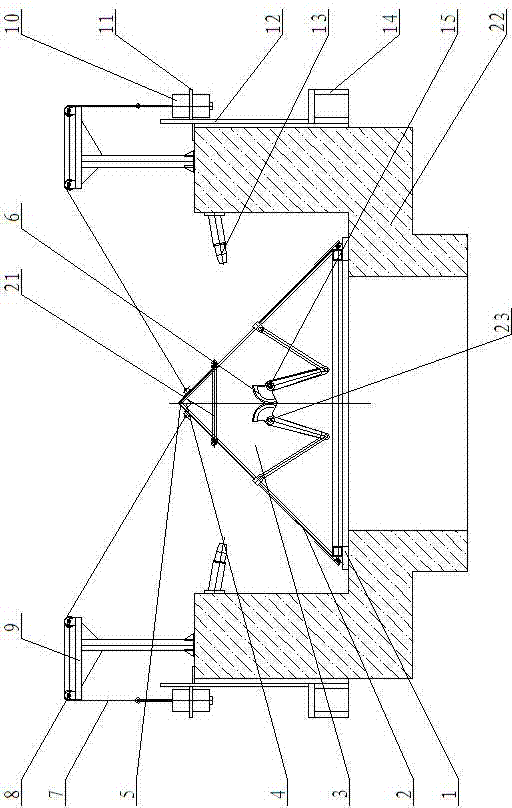

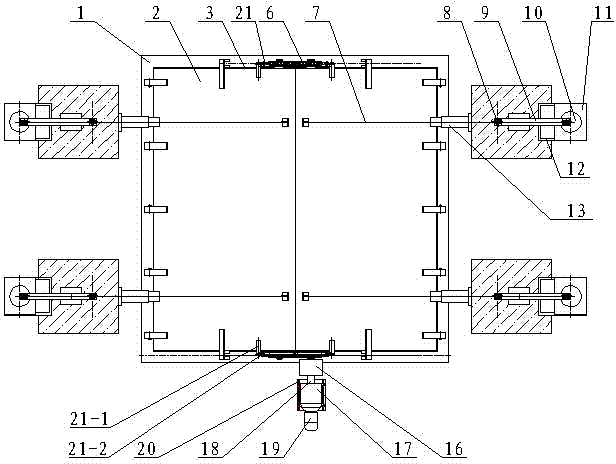

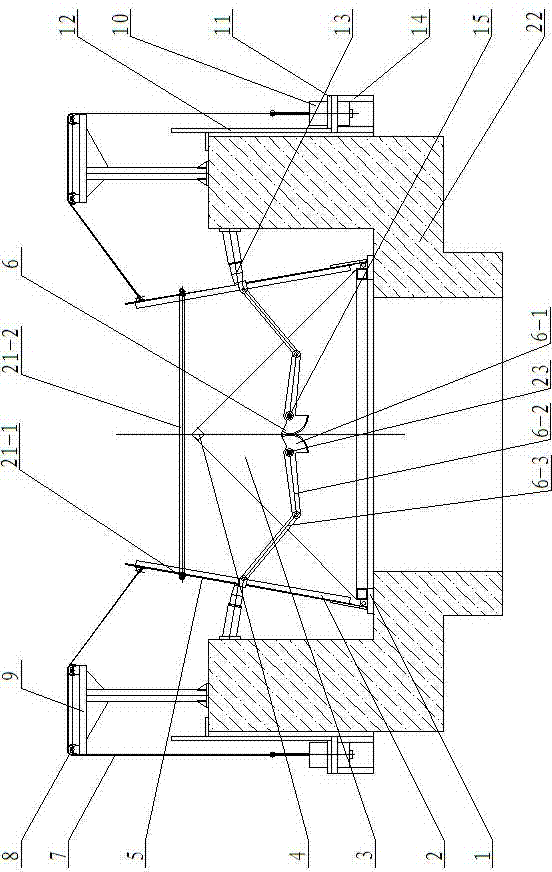

[0030] Such as figure 1 As shown in -5, the present invention mainly includes a square sealing base 1 arranged on the wellhead foundation 22, and isosceles triangular side risers 3 are welded on the front and rear sides above the square seal base 1, and two side risers 3 The upper ends are connected by square beams 4. The left and right sides above the square sealing base 1 are hinged with oblique opening doors 2, and the inner sides of each oblique opening door 2 are connected with hollow flexible rubber plates 5, which are connected with the two hypotenuses of the square beam 4 and the side vertical plate 3. , The square sealing base 1 cooperates to realize sealing.

[0031] The explosion-proof door also includes two groups of extension spring assemblies 21, and each group of extension spring assemblies 21 includes two extension spring mounts 21-1 and an extension spring 21-2, and each extension spring mount 21-1 is connected to a corresponding oblique Pull open the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com