Engineering machinery cooling system

A technology of cooling system and construction machinery, applied in the direction of engine cooling, mechanical equipment, coolant flow control, etc., can solve the problems of overheating or undercooling, poor cooling effect, loud fan noise, etc., to reduce power consumption and emissions The effect of improving and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

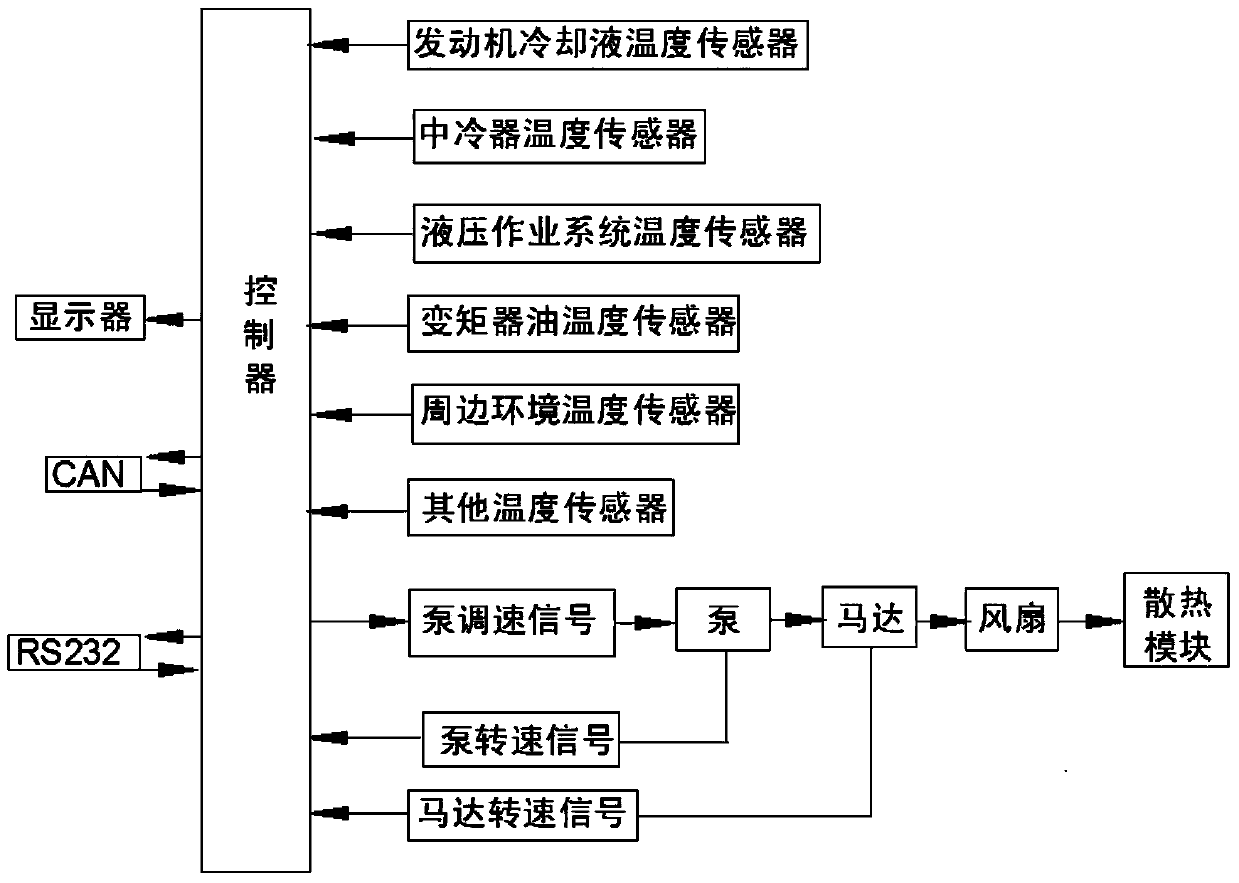

[0019] See figure 1 As shown, a construction machinery cooling system includes a display, a controller, a sensor, a pump, a motor, a fan and a heat dissipation module. The input end of the controller is connected with a sensor, and the output end is connected with a display and a pump. The display and The sensor is connected to the controller through a line, and the pump is connected to the controller through a pump speed regulation signal, where the speed regulation signal is a current signal or a PWM signal, the motor is connected to the pump through a hydraulic pipeline, and the fan is set at The output shaft end of the motor, wherein the sensor transmits the temperature signal of each device to the controller, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com