A heat-dissipating bearing

A technology for bearings and outer rings of bearings, applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., can solve the problems of shortening the service life of bearings, destroying the working environment, easy to rust and wear, etc., and achieve low rotation noise and heat dissipation performance Good, good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

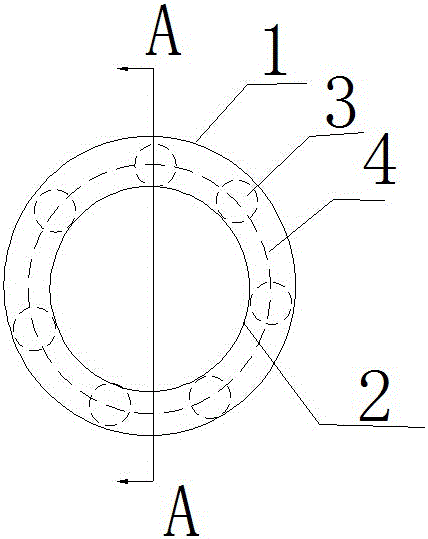

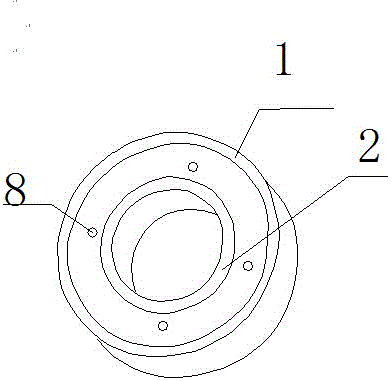

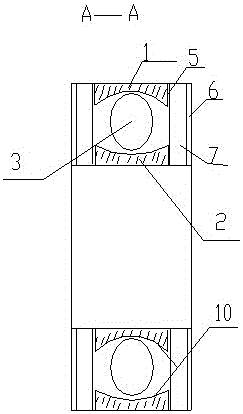

[0016] Such as figure 1 As described above, a heat-dissipating bearing includes a bearing outer ring 1 and a bearing inner ring 2. Several rolling elements 3 are arranged between the bearing inner ring 2 and the bearing outer ring 1. The bearing outer ring 1 is close to the rolling One side of the body 3 is concave, and the side of the bearing inner ring 2 close to the rolling body 3 is concave, such as image 3 The concave surface of the bearing outer ring 1 and the bearing inner ring 2 as shown constitutes an arc surface 10, and the arc surface 10 is connected with the rolling elements 3, and a fixing frame 4 is arranged between the rolling elements 3, and the bearing A sealing ring 5 is provided between the outer ring 1 and the inner ring 2 of the bearing. The thickness of the sealing ring 5 is 30mm-100mm. The sealing ring 5 isolates the rolling elements 3 from the outside world. A pressure plate is arranged outside the sealing ring 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com