Brake micro-motion integrated control system of hydraulic transmission gearbox for forklift

A hydraulic transmission and control system technology, applied in the direction of transmission control, fluid pressure actuation device, components with teeth, etc. To avoid problems such as changes in conditions, to avoid the phenomenon of burning friction plates, humanize the driving performance, and improve the life of the braking system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

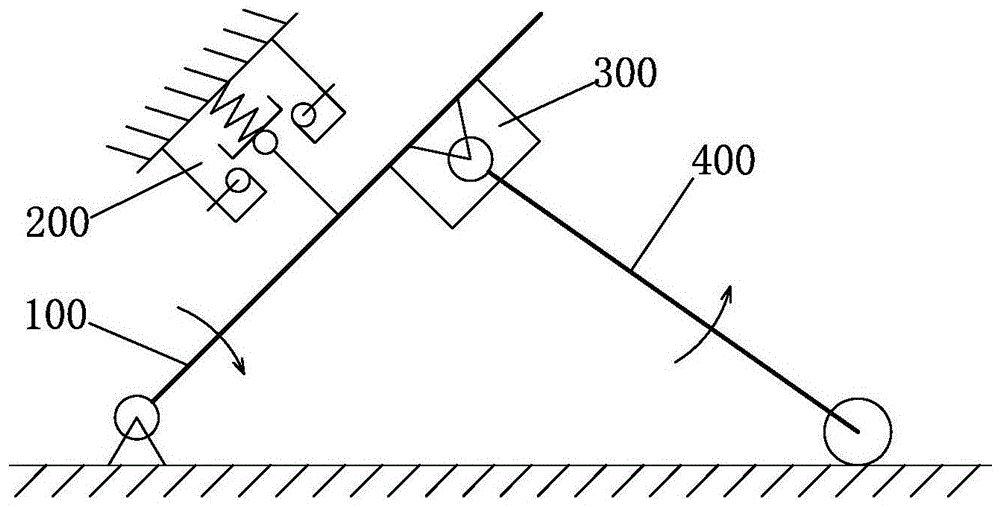

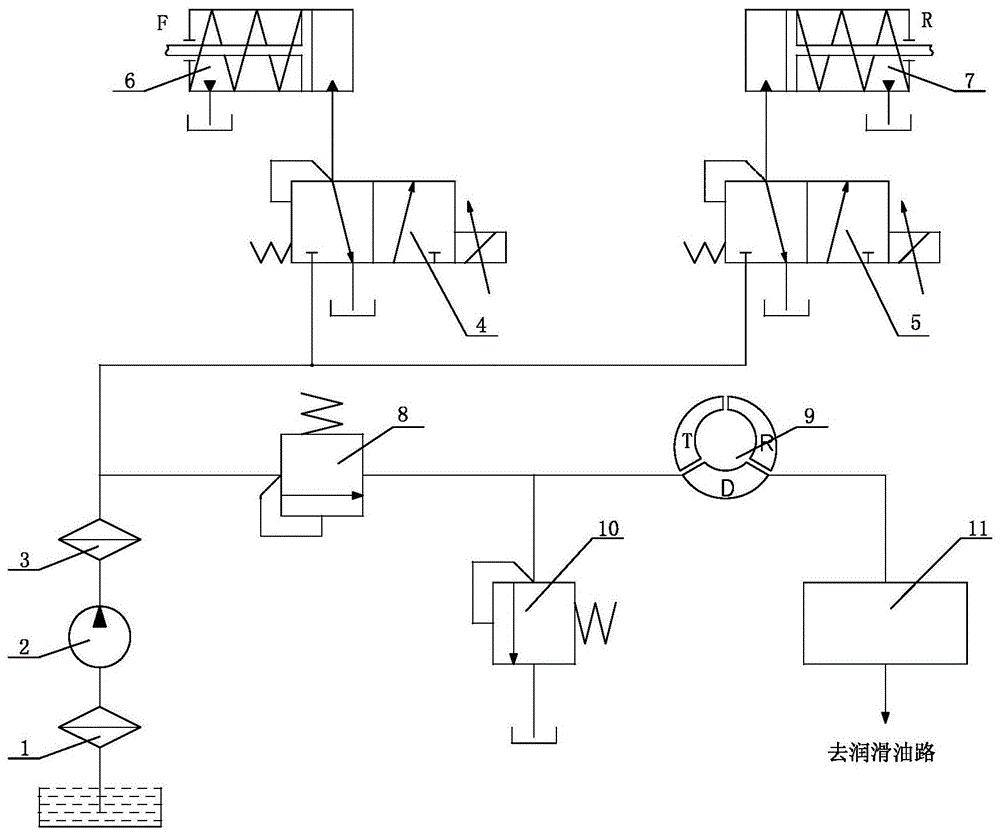

[0024] The brake micro-motion integrated control system of a hydraulic transmission gearbox for a forklift includes a pedal 100 installed on the forklift, a gearbox, an electronic control unit, a proportional hydraulic control system, and a forklift braking system. The pedal 100 is connected to the forklift braking system. Such as figure 1 As shown, the forklift is equipped with a position switch 200 triggered when the pedal 100 is reset upwards and a speed sensor or a displacement sensor 300 that monitors the movement of the pedal 100; figure 2 As shown, the proportional hydraulic control system includes an oil pump 2, a main pressure regulating valve 8, a hydraulic torque converter 9, a relief valve 10 and a cooler 11, and the F clutch 6 in the gearbox passes through the electro-hydraulic proportional reversing valve. It is connected with the output end of the oil pump 2. The R clutch 7 in the gearbox is connected with the output end of the oil pump 2 after passing through ...

Embodiment 2

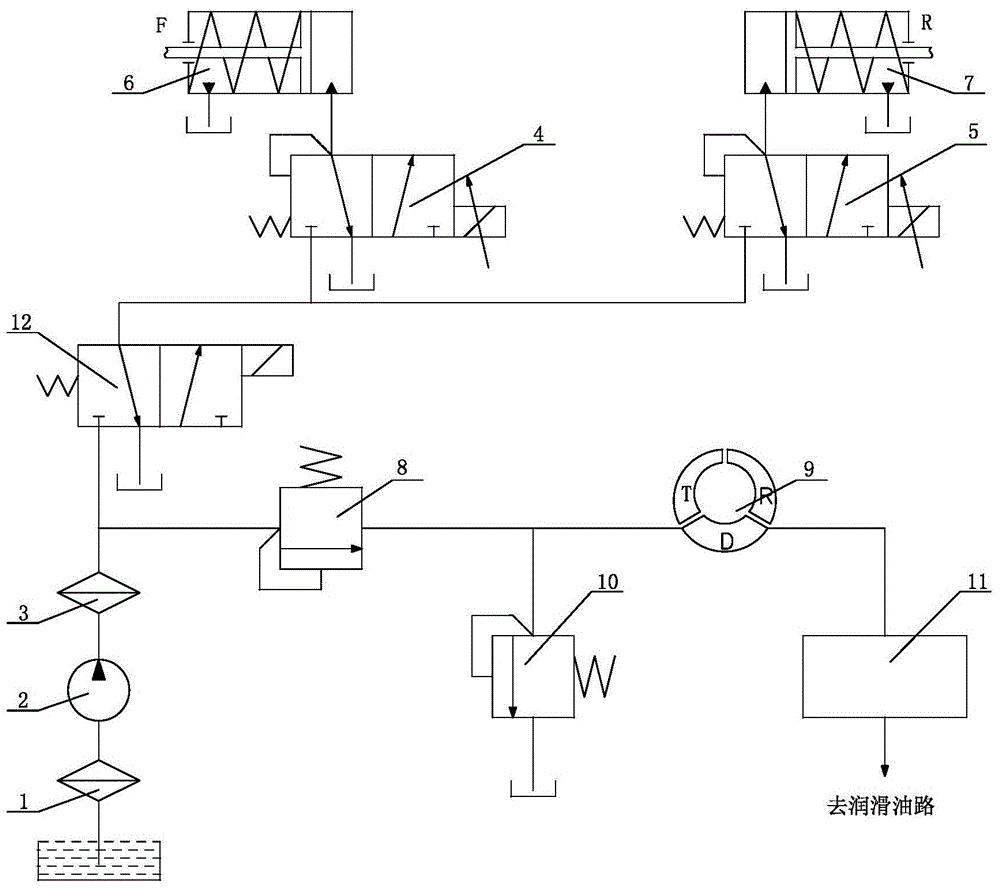

[0029] The brake micro-motion integrated control system of the hydraulic transmission gearbox for forklifts differs from Embodiment 1 only in the proportional hydraulic control system, such as image 3 As shown, the F clutch 6 is connected to the two-position three-way electro-hydraulic proportional reversing valve A4, the R clutch 7 is connected to the two-position three-way electro-hydraulic proportional reversing valve B5, and the electro-hydraulic proportional reversing valve A4 is connected to the electro-hydraulic proportional reversing valve After the valve B5 is connected in parallel, it is connected to the output end of the oil pump 2 through the two-position three-way electromagnetic reversing valve 12; Both the clutch 6 and the R clutch 7 are connected to the oil circuit, they are both in the separated state, there is no power transmission, and the gearbox is in the neutral state; when the electromagnetic reversing valve 12 and the electro-hydraulic proportional reve...

Embodiment 3

[0031] The brake micro-motion integrated control system of the hydraulic transmission gearbox for forklifts differs from Embodiment 1 only in the proportional hydraulic control system, such as Figure 4 As shown, the F clutch 6 is connected to the electromagnetic reversing valve A13, and the R clutch 7 is connected to the electromagnetic reversing valve B14. After the two-position three-way electromagnetic reversing valve A13 and the two-position three-way electromagnetic reversing valve B14 are parallel connected The two-position three-way electro-hydraulic proportional reversing valve 15 is connected to the output end of the oil pump 2; when the electromagnetic reversing valve A13, the electromagnetic reversing valve B14 and the electro-hydraulic proportional reversing valve 15 are not working, both the F clutch 6 and the R clutch 7 The return oil circuit is in a separated state, there is no power transmission, and the gearbox is in the neutral state; when the electro-hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com