Method of Measuring Air Specific Heat Capacity Ratio by Vibration of Piston in Cylinder with Both Ends Sealed

A technology of specific heat capacity ratio and inner piston, applied in the direction of analyzing materials, instruments, etc., can solve the problems of difficulty in realization, rotational uncertainty, lack of simple harmonic vibration, etc., and achieve the effect of simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

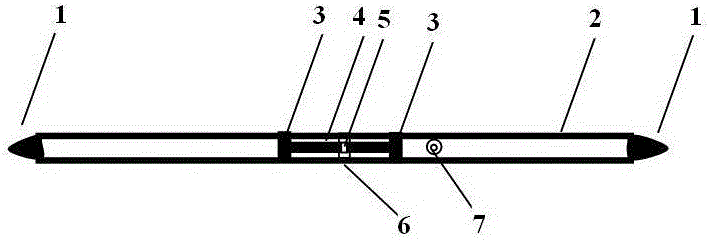

[0013] A cylinder 2 made of transparent hard material (hard transparent material is glass, hard plastic, etc., which can withstand pressure, and the deformation caused by pressure is relatively small and negligible) has external threads at both ends, which can pass The external thread of the cylinder 2 and the internal thread of the sealing cap 1 realize the sealing of the air inside the cylinder (using a gasket) at both ends of the cylinder 2. This sealing is a prior art and can be a common nut (equivalent The sealing cap of the device), threads, gaskets, or other sealing methods; there are two cylinder center rings 6 at the center of the outside of the cylinder 2, and the center of the two cylinder center circles 6 is the symmetrical center of the cylinder 2 , in other words, the distance from the center of symmetry to the ends of the cylinder 2 is equal, there is a horizontal bubble 7 on the outer surface of the cylinder 2, and the cylinder 2 is fixed on a bracket (for the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com