Shale gas content determining method and determining system of shale gas content determining method

A measurement method and measurement system technology, which can be used in measurement devices, special data processing applications, material analysis by optical means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

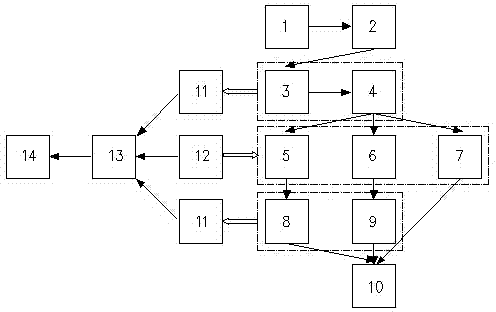

[0021] Further illustrate the present invention in conjunction with accompanying drawing and example, the method of the present invention is to take computer as processor, under the support of relevant program, there is no piezoresistance in the whole measurement process, promptly open measurement, by program automatic control electromagnetic valve, automatic Collect the parameters of desorption temperature, gas composition, gas flow, atmospheric pressure and ambient temperature, self-correct, self-organize, and automatically calculate the total desorption gas volume and loss gas volume.

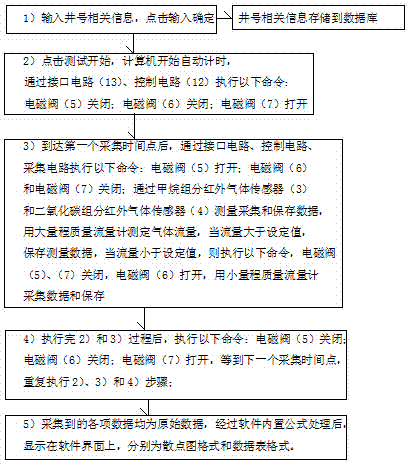

[0022] Such as figure 2 As shown, the procedure includes the following steps:

[0023] 1) Enter the relevant information of the number number, click Enter to confirm, and the relevant information of the number number will be stored in the database;

[0024] 2) Click to start the test, and the computer starts automatic timing, and executes the following commands through the interface circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com