Intelligent selection method and system for numerical control machining tools

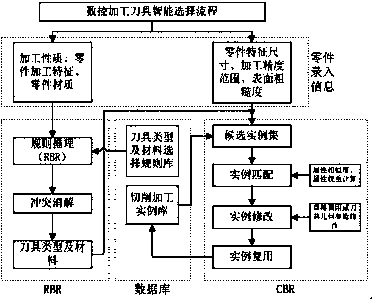

A technology for intelligent selection and machining of tools, applied in general control systems, control/regulation systems, program control, etc., it can solve the problems of high professional requirements for craftsmen and complex tool preparation, and achieve the effect of reducing professional requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

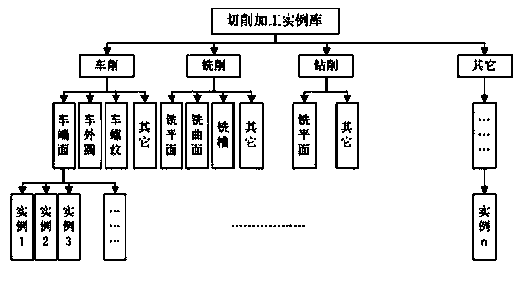

Method used

Image

Examples

Embodiment 1

[0058] Take the actual production of an elevator parts manufacturer in Nantong, Jiangsu as an example. Process a batch of magnet mounting plates. The material of the parts is 40Cr. The surface is semi-finish milled. The surface length of the parts is 24cm and the width is 20cm. The required accuracy range is [-0.5, +0.5] and the surface roughness is 1.0.

[0059] Step 1: First, the user enters in the part information input module that the processing feature of the part is milling plane, the material of the part is 40Cr, and the processing property is semi-finishing.

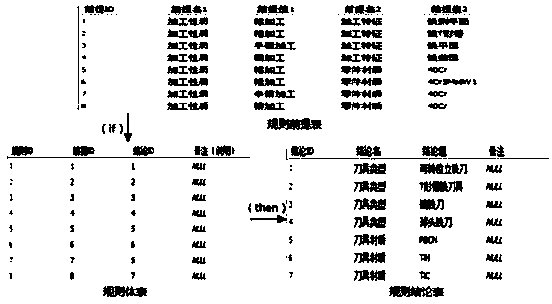

[0060] Step 2: The system will output that the tool type of the tool to be selected is end mill, and the tool material is PBCN. The triggering rules are as follows:

[0061] IF part processing feature = milling plane and processing property = semi-finishing THEN tool type = end mill

[0062] IF part material = 40Crand processing property = semi-finishing THEN tool material = PBCN

[0063] The third step: then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com