Special installation structure and installation method for external wall insulation board

A technology for external wall thermal insulation boards and installation structures, which is applied in thermal insulation, building components, building structures, etc., can solve the problems of increased construction difficulty, higher precision requirements, and poor randomness, etc., so as to reduce construction difficulty, Guaranteed construction quality and reduced installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

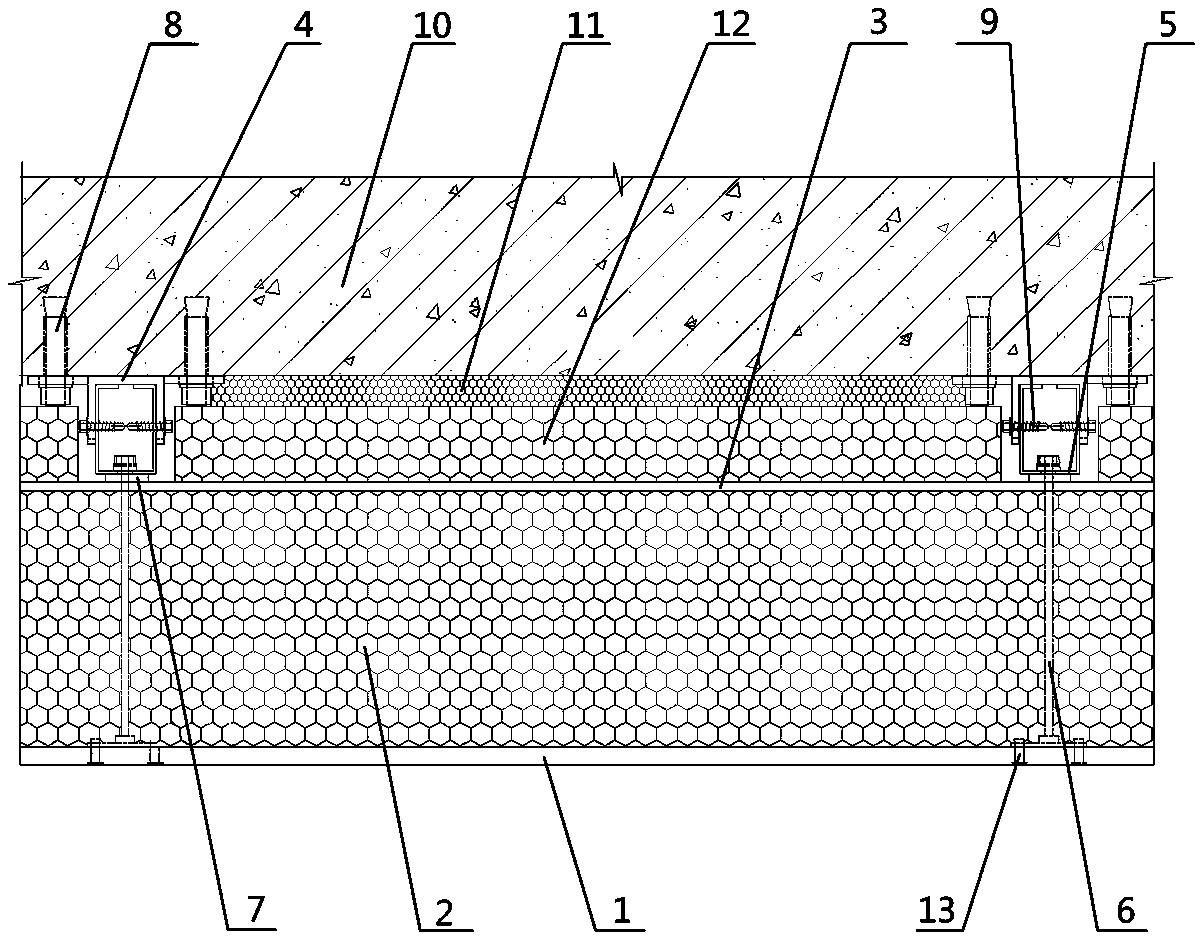

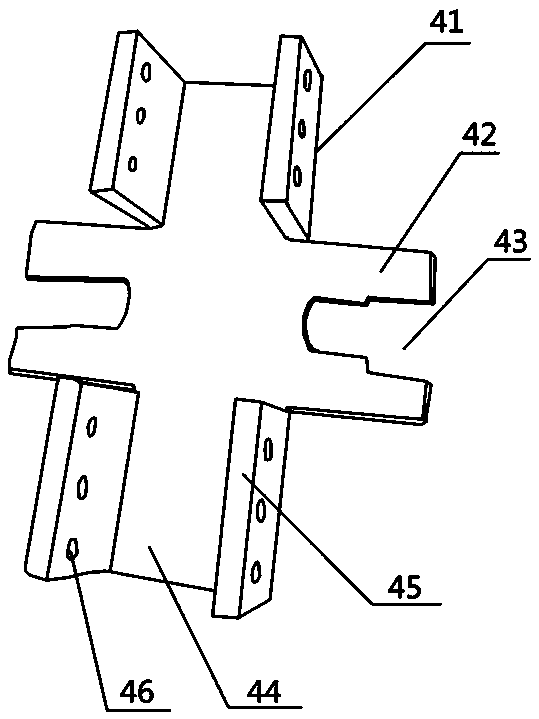

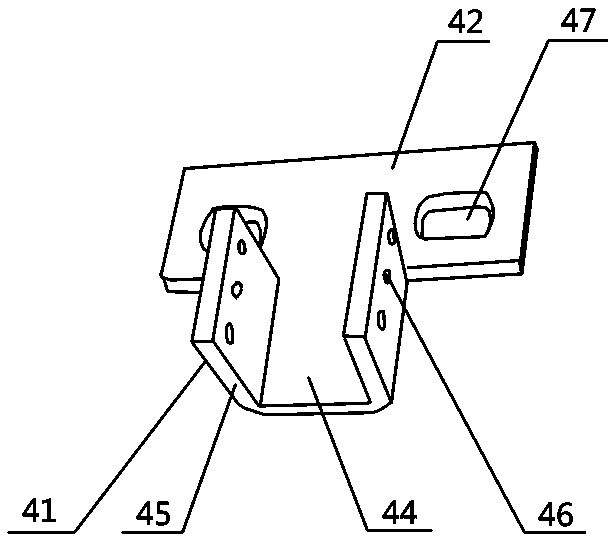

[0040] There is a consensus in the construction industry that it is impossible to control the assembly accuracy of prefabricated insulation and decoration integrated hanging panels within 2mm. It is true that no practical technical solutions have been seen for many years. Either directly imitate the installation method of the stone curtain wall, or make a slight improvement. Its effect, not only there is potential safety hazard, and construction cost is too high. Through technological innovation, the present invention has designed a key component that can accurately position the vertical keel in the three dimensions of "up and down", "left and right", and "front and back". The key component is the anchor plate structure in the present invention . like figure 1 As shown, the anchor plate 4 in the present invention is attached to the wall body 10, and its design concept is ingenious, which can solve the three-dimensional positioning problem of the vertical keel 5 easily.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com