A well testing machine control system

A control system and well testing rig technology, applied in the directions of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of low service life of switch components, cumbersome system stroke adjustment process, small torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

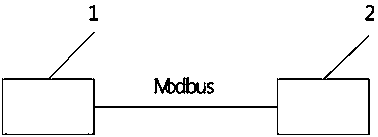

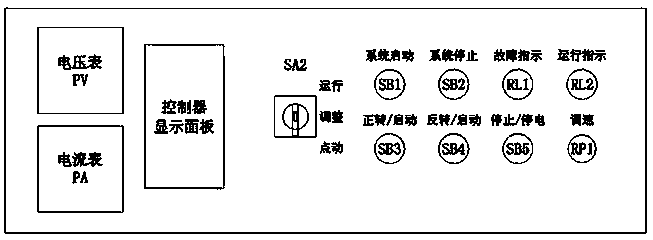

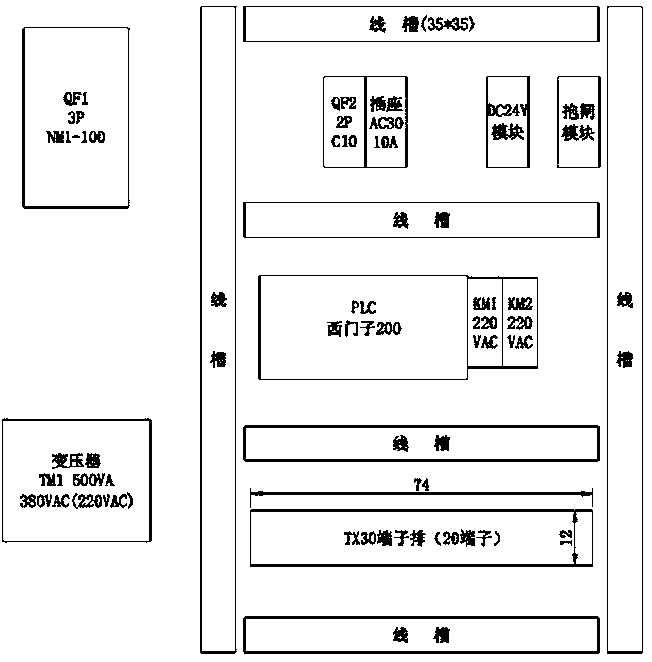

[0025] Such as Figure 1 to Figure 7 As shown, a well testing rig control system according to the present invention includes: a switched reluctance motor controller 1, a host computer controller 2, and the communication between the switched reluctance motor controller 1 and the host computer controller 2 is carried out through Modbus connect.

[0026] Among them, the upper computer controller 2 is a programmable logic controller (Programmable Logic Controller, PLC), from I0.0 to I2.2 are the input points of the upper computer controller 2, and from Q0.0 to Q1.7 are the upper computer The output point of the controller 2, the upper computer controller 2 realizes the communication based on the Modbus protocol with the switched reluctance motor controller 1 through programming. The upper computer controller 2 is connected to the switched reluctance motor controller 1 (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com