Method for producing aqueous solution of perrhenic acid from rhenium sulfide

A manufacturing method and technology for aqueous solutions, applied in chemical instruments and methods, rhenium compounds, inorganic chemistry, etc.

Active Publication Date: 2015-01-07

PAN PACIFIC COPPER CO LTD

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On this point, although it is described in Patent Document 3 that rhenium sulfide is oxidized to rhenium oxide by roasting, and that rhenium oxide is gasified at a temperature above 150° C. and accumulated in dust, the removal of impurities is still unclear. room for improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0070] Hereinafter, examples of the present invention will be described, but the examples are for the purpose of illustration and are not intended to limit the invention.

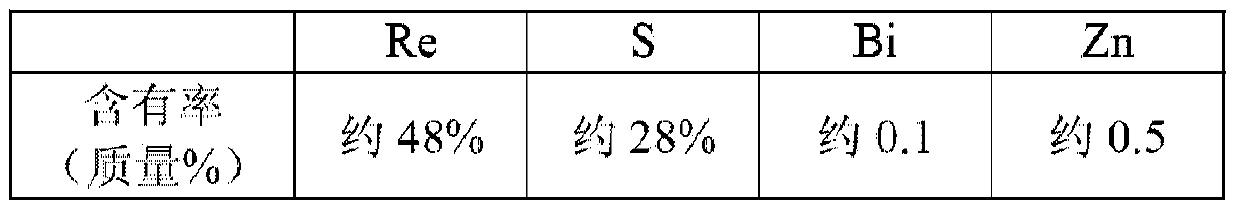

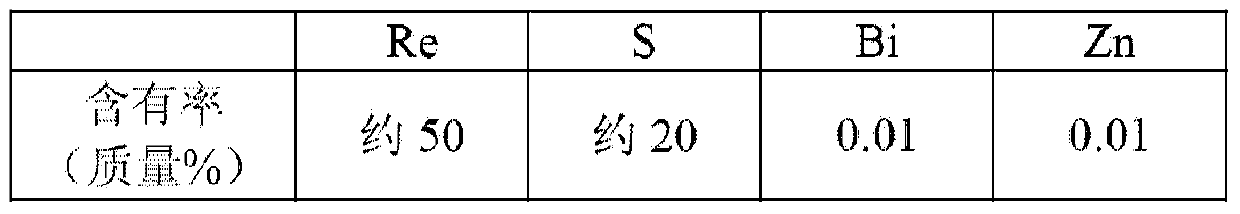

[0071] (Research on the influence of roasting conditions on the gasification rate of each component)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen equivalent | aaaaa | aaaaa |

Login to View More

Abstract

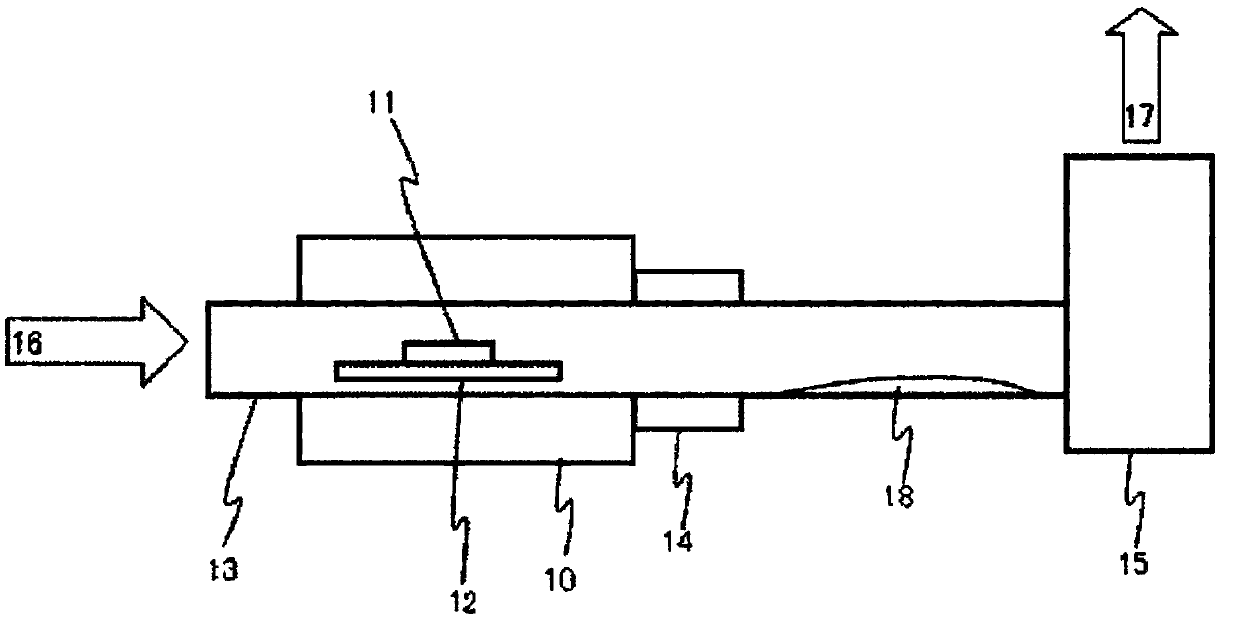

Provided is a method that enables high-purity perrhenic acid to be produced from crude rhenium sulfide using a dry process. This method for producing an aqueous solution of perrhenic acid includes: 1) a step in which roasting is performed on rhenium sulfide in the presence of an oxygen-containing gas, and gasified rhenium oxide is collected; 2) a step in which the rhenium oxide is cooled and solidified, while keeping sulfur oxides associated with the gasified rhenium oxide in a gaseous state, and then the purity of the rhenium oxide is increased by performing solid-gas separation; and 3) a step in which an aqueous solution of perrhenic acid is obtained by dissolving the solidified rhenium oxide in water, or by dissolving the solidified rhenium oxide in water after heating and gasifying the solidified rhenium oxide.

Description

technical field [0001] The present invention relates to a method for producing an aqueous perrhenic acid solution from rhenium sulfide. In particular, the invention relates to a process for the production of ammonium perrhenate from rhenium sulfide via perrhenic acid. Background technique [0002] Rhenium is a rare metal that accompanies only molybdenite ore and copper ore, and is an important metal used as an additive element for catalysts, an additive element for thermocouples and superalloys, and a material for high-vacuum electron tubes. [0003] As one of the promising raw materials for recovering rhenium industrially, there is crude rhenium sulfide. Examples of impurities in crude rhenium sulfide include zinc, bismuth, and the like. [0004] Conventionally, there is known a method for producing potassium perrhenate from rough rhenium sulfide as described in JP-A-62-148327 (Patent Document 1). In this document, crude rhenium sulfide is oxidized and leached using an o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01G47/00C22B1/02C22B3/44C22B5/12C22B61/00

CPCC22B1/02C22B61/00C22B5/12C01G47/00C22B3/44

Inventor 隅田育伸河野雄仁浜本真

Owner PAN PACIFIC COPPER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com