A kind of preparation method of hydraulic gelling material

A hydraulic gelling and hard technology, applied in the field of cement-based materials, can solve the problems of poor adaptability of admixtures, limited industrialization promotion, and difficult to be widely used, and achieve excellent fireproof and thermal insulation performance, reduce production costs, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

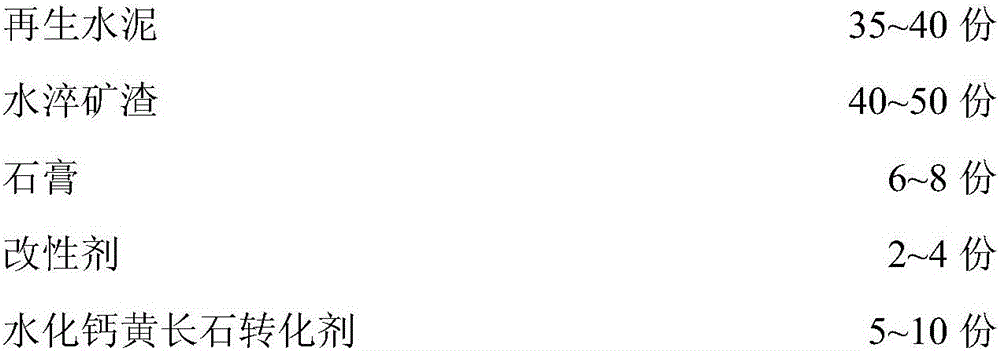

[0026] ①The above-mentioned components are mixed according to the weight ratio, wherein:

[0027] 36 parts of recycled cement, 49 parts of water-quenched slag, 6 parts of calcined anhydrite, 4 parts of potassium dihydrogen phosphate, and 5 parts of metakaolin.

[0028] ② Use a pulverizer to coarsely pulverize the above mixture into particles with a particle size of less than 2.5mm.

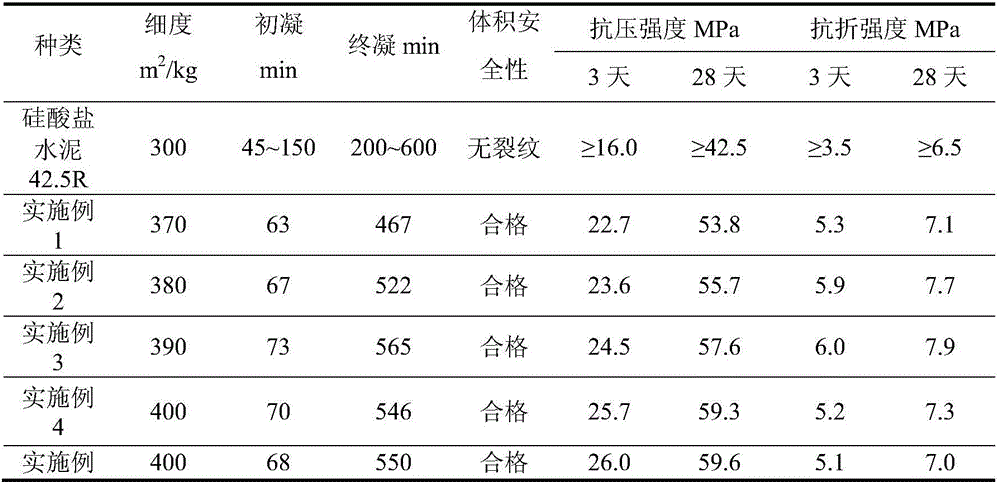

[0029] ③Use a fine grinder to further grind the particles to a fineness of 370m 2 / kg.

Embodiment 2

[0031] ①The above-mentioned components are mixed according to the weight ratio, wherein:

[0032] 35 parts of recycled cement, 50 parts of water-quenched slag, 6 parts of anhydrite calcined product, 3 parts of sodium dihydrogen phosphate, and 6 parts of alumite calcined powder.

[0033] ② Use a pulverizer to coarsely pulverize the above mixture into particles with a particle size of less than 3mm.

[0034] ③Use a fine grinder to further grind the particles to make the fineness 380m 2 / kg.

Embodiment 3

[0036] ①The above-mentioned components are mixed according to the weight ratio, wherein:

[0037] 37 parts of recycled cement, 46 parts of water-quenched slag, 8 parts of anhydrite calcined product, 2 parts of ammonium dihydrogen phosphate, and 7 parts of alumite calcined powder.

[0038] ② Use a pulverizer to coarsely pulverize the above mixture into particles with a particle size of less than 3.5 mm.

[0039] ③Use a fine grinder to further grind the particles to make the fineness 390m 2 / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com