Preparation method of graphene-doped conductive composite fiber

A conductive composite fiber and graphene technology, which is applied in the manufacture of conductive/antistatic filaments, fiber chemical characteristics, and complete sets of equipment for the production of artificial threads, can solve the problems of low fiber strength and low conductivity of conductive fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

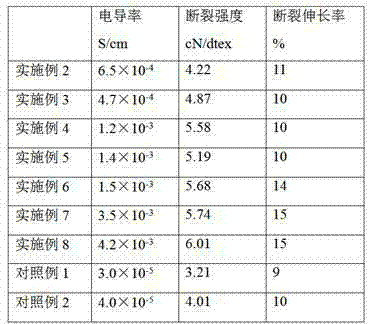

Examples

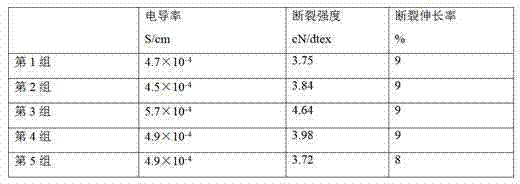

Embodiment 1

[0035] The preparation method of the conductive composite fiber doped with graphene, comprises the steps:

[0036] Step 1, mix and stir graphene 10Kg, dispersant 2Kg, high molecular polymer 100Kg; described high molecular polymer is mixed by 1,2-polybutadiene, acrylic resin, chlorinated polypropylene, polypropylene (mixing weight ratios are 1:1:1:2, 1:1:2:2, 1:1:3:2, 1:1:4:2, 1:1:5:2; respectively referred to as groups 1, 2, 3, 4, 5); the dispersant is coconut acid diethanolamide;

[0037] The 2nd step, use the twin-screw extruder to melt the mixture prepared in the first step, filter, spin, cool and form, stretch and heat-set to prepare the conductive composite fiber; the rotating speed of the twin-screw extruder is 100rpm, the pressure is 50kg / cm; in the twin-screw heating area, the temperature in the first zone is 190°C, the temperature in the second zone is 210°C, the temperature in the third zone is 220°C, and the temperature in the fourth zone is 200°C; the spinning spe...

Embodiment 2

[0043] The preparation method of the conductive composite fiber doped with graphene, comprises the steps:

[0044] The 1st step, Graphene 15Kg, dispersant 4 Kg, polymer 150 Kg are mixed and stirred; Described polymer is made of 1,2-polybutadiene, acrylic resin, chlorinated polypropylene, polypropylene Propylene is mixed (the weight ratio of mixing is 1:1:3:2); the dispersant is coconut acid diethanolamide;

[0045] The 2nd step, use the twin-screw extruder to melt the mixture prepared in the first step, filter, spin, cool and form, stretch and heat-set to prepare the conductive composite fiber; the rotating speed of the twin-screw extruder is 150rpm, the pressure is 80kg / cm; in the twin-screw heating area, the temperature in the first zone is 230°C, the temperature in the second zone is 240°C, the temperature in the third zone is 240°C, and the temperature in the fourth zone is 220°C; the spinning speed is 2000m / min; step 2 The medium stretching process is as follows: the tem...

Embodiment 3

[0048] The preparation method of the conductive composite fiber doped with graphene, comprises the steps:

[0049] Step 1, mix and stir graphene 12Kg, dispersant 3Kg, high molecular polymer 120 Kg; Described high molecular polymer is made of 1,2-polybutadiene, acrylic resin, chlorinated polypropylene, polypropylene Mixed (the weight ratio of mixing is 1:1:3:2); the dispersant is coconut acid diethanolamide;

[0050]The 2nd step, use the twin-screw extruder to melt the mixture prepared in the first step, filter, spin, cool and form, stretch and heat-set to prepare the conductive composite fiber; the rotating speed of the twin-screw extruder is 120rpm, the pressure is 70kg / cm; in the twin-screw heating area, the temperature in the first zone is 200°C, the temperature in the second zone is 230°C, the temperature in the third zone is 230°C, and the temperature in the fourth zone is 210°C; the spinning speed is 1400m / min; step 2 The medium stretching process is as follows: the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com