PVC (polyvinyl chloride) floor with noise reduction and elastic functions

A technology of elasticity and flooring, applied in the direction of elastic flooring, chemical instruments and methods, layered products, etc., can solve the problems of unfavorable home use, large spring group elasticity, poor elastic function, etc., to reduce noise, avoid stress cracking, and good Effects of bearing capacity and load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

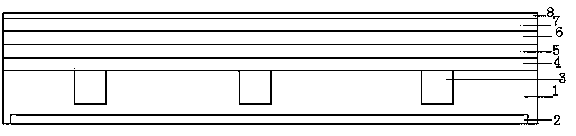

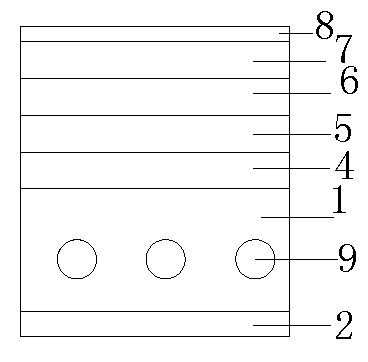

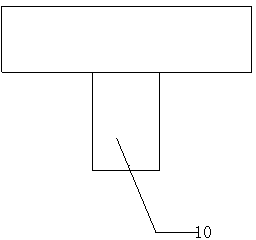

[0020] The present invention is a PVC floor with sound-absorbing and elastic functions, including a base material layer 1, an insulating and waterproof MPPO layer 2 is embedded inside the base material layer 1, and the base material layer 1 is a fiberboard. The MPPO layer is embedded in the substrate layer, and the embedded design is adopted. The bearing capacity of the floor is on the substrate layer, which can avoid MPPO stress cracking, and can well reflect the insulation, waterproof, and steam resistance of the MPPO layer. Advantages, three moisture-proof sound-absorbing holes 3 are arranged inside the base material layer 1, and the materials put into the three moisture-proof sound-absorbing holes 3 are respectively vermiculite, foam glass, expanded perlite or vermiculite, vermiculite, Vermiculite or foam glass, foam glass, foam glass or expanded perlite, expanded perlite, expanded perlite Vermiculite not only has the function of sound attenuation, but also can add essentia...

Embodiment 2

[0022]The present invention is a PVC floor with sound-absorbing and elastic functions, comprising a base material layer 1, an insulating and waterproof MPPO layer 2 is embedded inside the base material layer 1, and the base material layer 1 is fiberboard or solid wood The bonding layer of board or fiberboard and solid wood board is embedded with MPPO layer in the base layer, and the embedded design is adopted. The bearing capacity of the floor is on the base layer, which can avoid MPPO stress cracking and can well reflect the MPPO layer. It has the advantages of insulation, waterproof, and steam resistance. Three moisture-proof sound-absorbing holes 3 are arranged inside the base material layer 1, and the materials put in the three moisture-proof sound-absorbing holes 3 are vermiculite and vermiculite respectively in order. , foam glass or vermiculite, vermiculite, expanded perlite or vermiculite, foam glass, foam glass or vermiculite, expanded perlite, expanded perlite or foam...

Embodiment 3

[0025] The present invention is a PVC floor with sound-absorbing and elastic functions, comprising a base material layer 1, an insulating and waterproof MPPO layer 2 is embedded inside the base material layer 1, and the base material layer 1 is fiberboard or solid wood The bonding layer of board or fiberboard and solid wood board is embedded with MPPO layer in the base layer, and the embedded design is adopted. The bearing capacity of the floor is on the base layer, which can avoid MPPO stress cracking and can well reflect the MPPO layer. It has the advantages of insulation, waterproof, and steam resistance. Three moisture-proof sound-absorbing holes 3 are arranged inside the base material layer 1, and the materials put in the three moisture-proof sound-absorbing holes 3 are vermiculite and foam glass in order. , expanded perlite or vermiculite, vermiculite, vermiculite or foam glass, foam glass, foam glass or expanded perlite, expanded perlite, expanded perlite or vermiculite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com