Air conditioning air deflector and manufacturing method of same

A technology of wind deflector and air conditioner, which is applied in noise suppression, space heating and ventilation details, heating methods, etc. It can solve the problems of air conditioner dripping water, fast heat conduction, condensation on the surface of wind deflector, etc., and achieve production cost reduction, Reduce the connection gap and reduce the effect of water droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

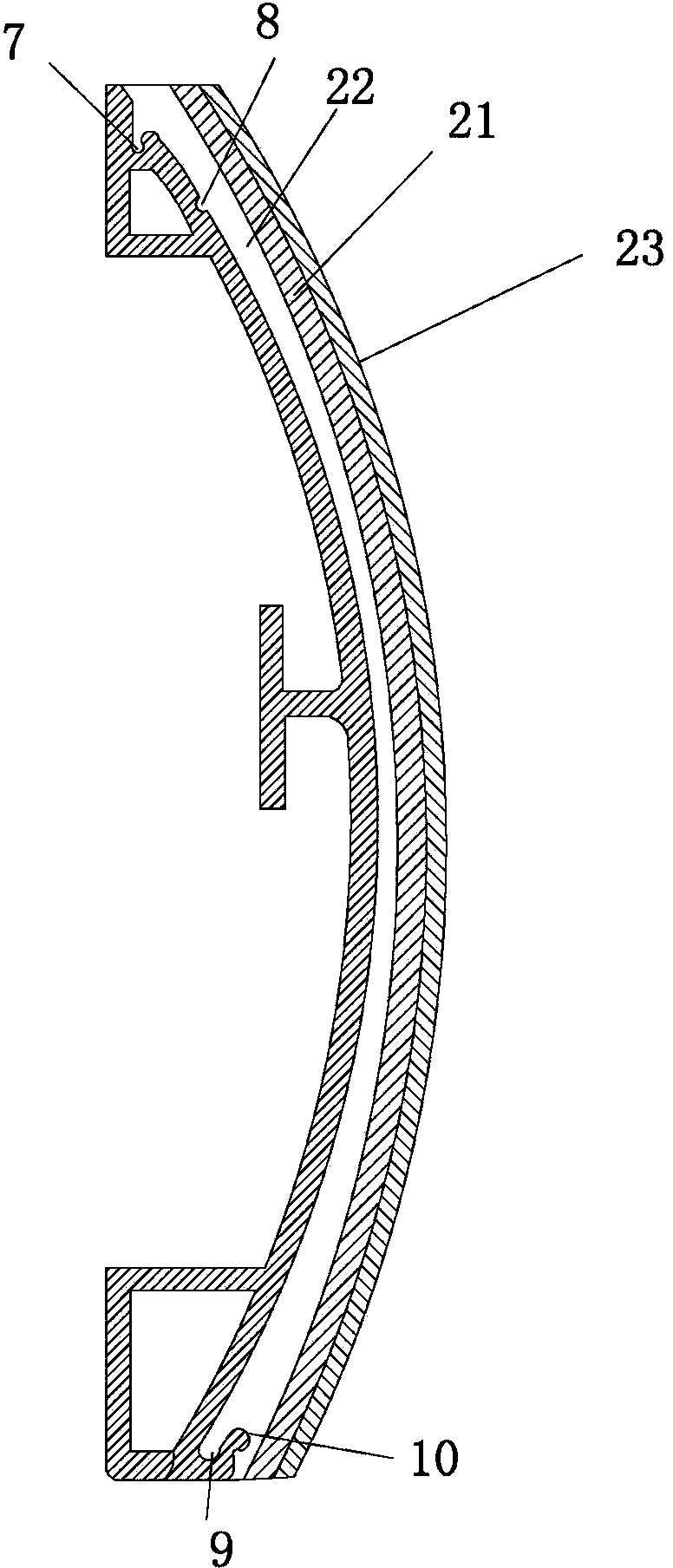

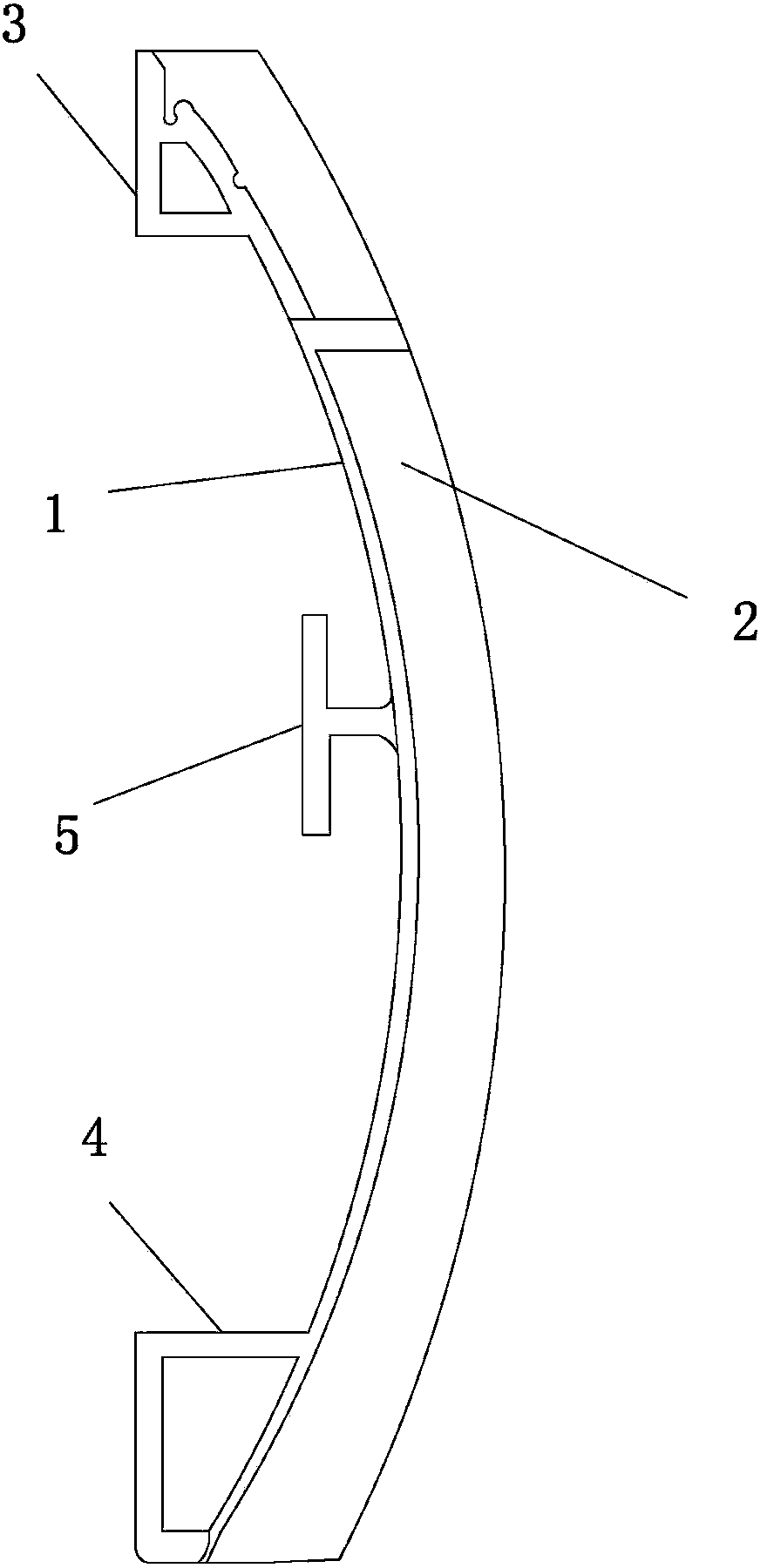

[0034] Embodiment 1: A method for making an air-conditioning wind deflector, comprising the following steps:

[0035] (1) Prepare materials, prepare metal profile plates, treat the surface of metal profile plates, and perform grinding, wire drawing, sandblasting, passivation and oxidation treatment on the surface of metal profile plates;

[0036] (2), spray PU paint, spray PU paint on the surface of the metal profile plate in step (1), and send the metal profile plate after spraying the PU paint into the oven for drying; the oven temperature is 60°C;

[0037] (3), spray PU resin glue, spray PU resin glue on the surface of the metal profile plate in step (2), and send the metal profile plate after spraying PU resin glue into the oven for drying; the oven temperature is 70°C;

[0038] (4) Inject PU polyurethane material, put the metal profile plate in step (3) into the metal mold, and inject PU polyurethane material through the injection molding machine until the PU polyurethane...

Embodiment 2

[0040] Embodiment 2: A method for making an air-conditioning wind deflector, comprising the following steps:

[0041] (1) Prepare materials, prepare metal profile plates, treat the surface of metal profile plates, and perform grinding, wire drawing, sandblasting, passivation and oxidation treatment on the surface of metal profile plates;

[0042] (2), spray PU paint, spray PU paint on the surface of the metal profile plate in step (1), and send the metal profile plate after spraying the PU paint into the oven for drying; the oven temperature is 70°C;

[0043] (3), spray PU resin glue, spray PU resin glue on the surface of the metal profile plate in step (2), and send the metal profile plate after spraying PU resin glue into the oven for drying; the oven temperature is 80°C;

[0044] (4) Inject PU polyurethane material, put the metal profile plate in step (3) into the metal mold, and inject PU polyurethane material through the injection molding machine until the PU polyurethane...

Embodiment 3

[0046] Embodiment 3: A method for making an air-conditioning wind deflector, comprising the following steps:

[0047] (1) Prepare materials, prepare metal profile plates, treat the surface of metal profile plates, and perform grinding, wire drawing, sandblasting, passivation and oxidation treatment on the surface of metal profile plates;

[0048] (2), spray PU paint, spray PU paint on the surface of the metal profile plate in step (1), and send the metal profile plate after spraying PU paint into the oven for drying; the oven temperature is 80 °C;

[0049] (3), spray PU resin glue, spray PU resin glue on the surface of the metal profile plate in step (2), and send the metal profile plate after spraying PU resin glue into the oven for drying; the oven temperature is 90°C;

[0050] (4) Inject PU polyurethane material, put the metal profile plate in step (3) into the metal mold, and inject PU polyurethane material through the injection molding machine until the PU polyurethane ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com