An operation method of an integrated system of optical fiber test equipment

An integrated system and optical fiber testing technology, which is applied in the field of optical fiber production, can solve the problems of unfavorable optical fiber rapid transfer optical fiber process control, complex optical fiber inspection process, and many testers, and achieve good temperature stability, good inter-insertion performance, and return The effect of large wave loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

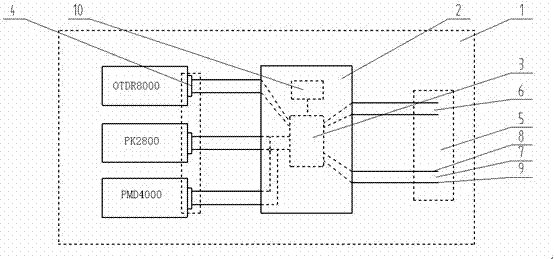

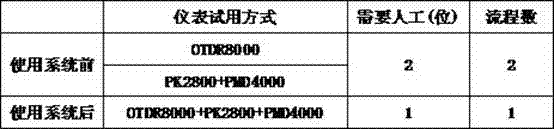

[0026] Such as figure 1 As shown, the test equipment integration system 1 of the present invention can rationally integrate resources through the optical path switching mode, realize that multiple instruments can be connected to each other, optical fibers can be connected at one time, and tests of different optical fiber indicators can be completed successively or simultaneously, thereby improving the operating personnel The work efficiency can also improve the use efficiency of test equipment. The test equipment integration system 1 can connect two test optical fibers and three test equipment at the same time. The test equipment integration system 1 includes an expansion module 2 and several tester groups communicating with the expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com