Electromagnetic valve service life testing system

A life test, solenoid valve technology, applied in the test of mechanical parts, the test of machine/structural parts, and the measurement of electricity, etc., can solve the problems of the life of the solenoid valve, the high test cost, and the impact of the life of the solenoid valve, and saves money. The effect of water and electricity, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

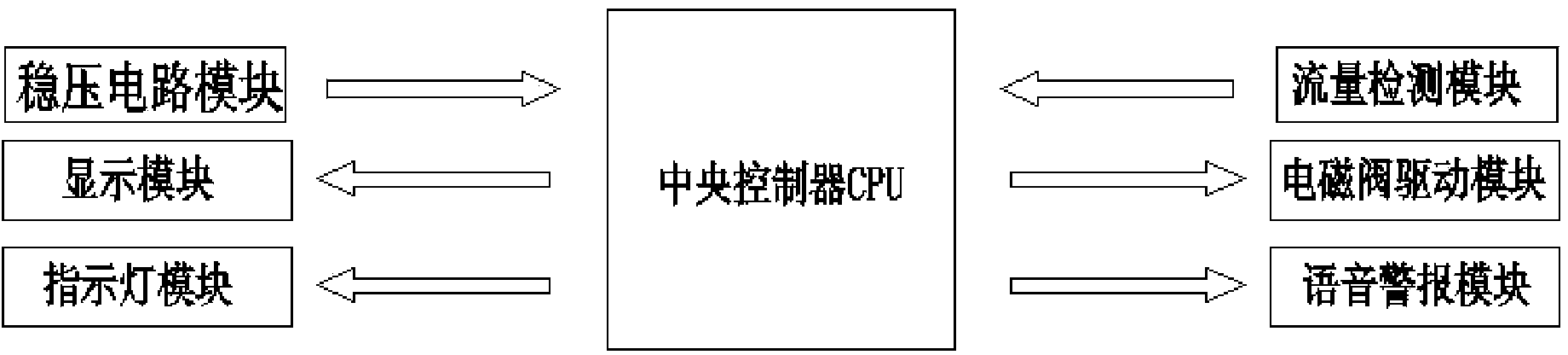

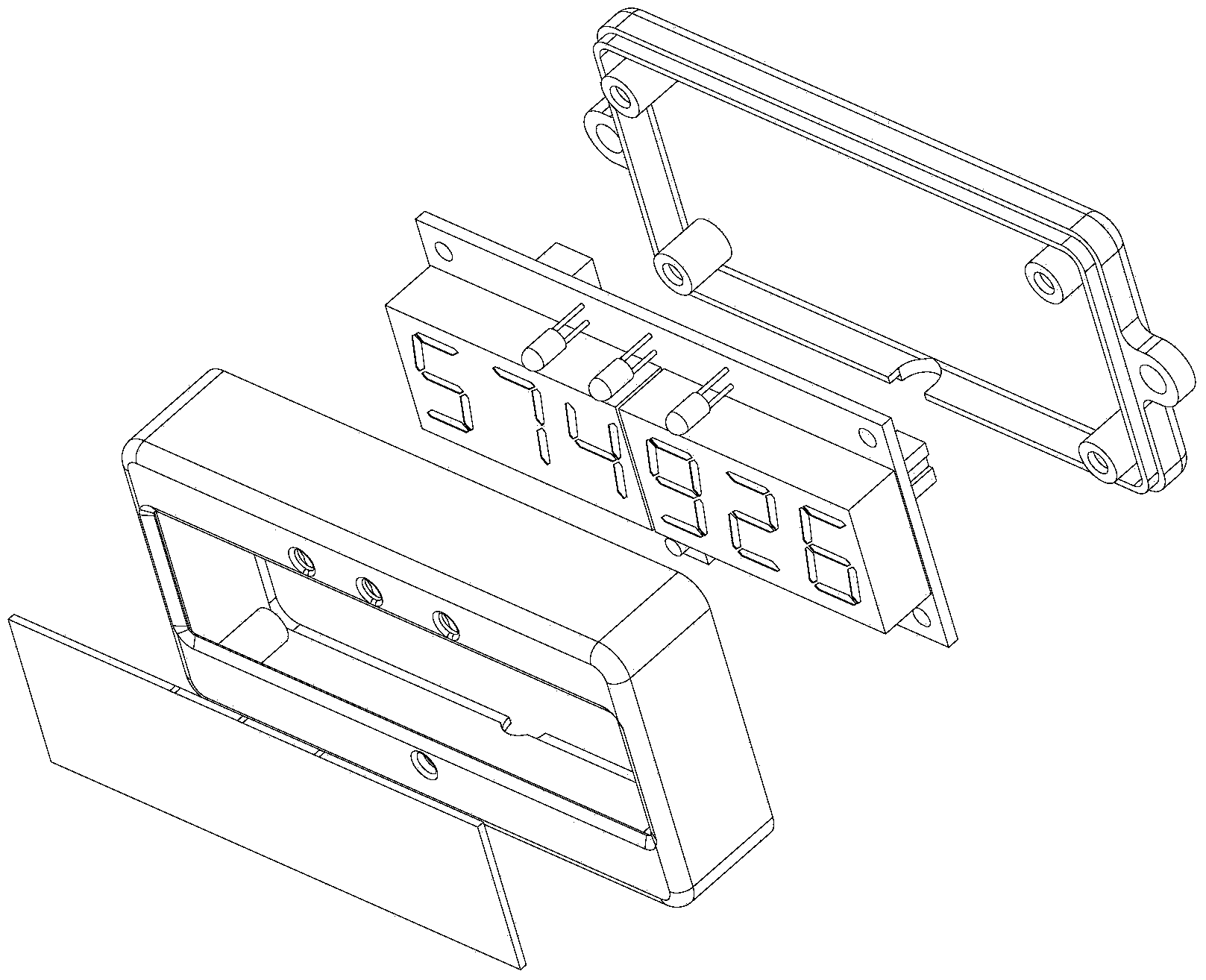

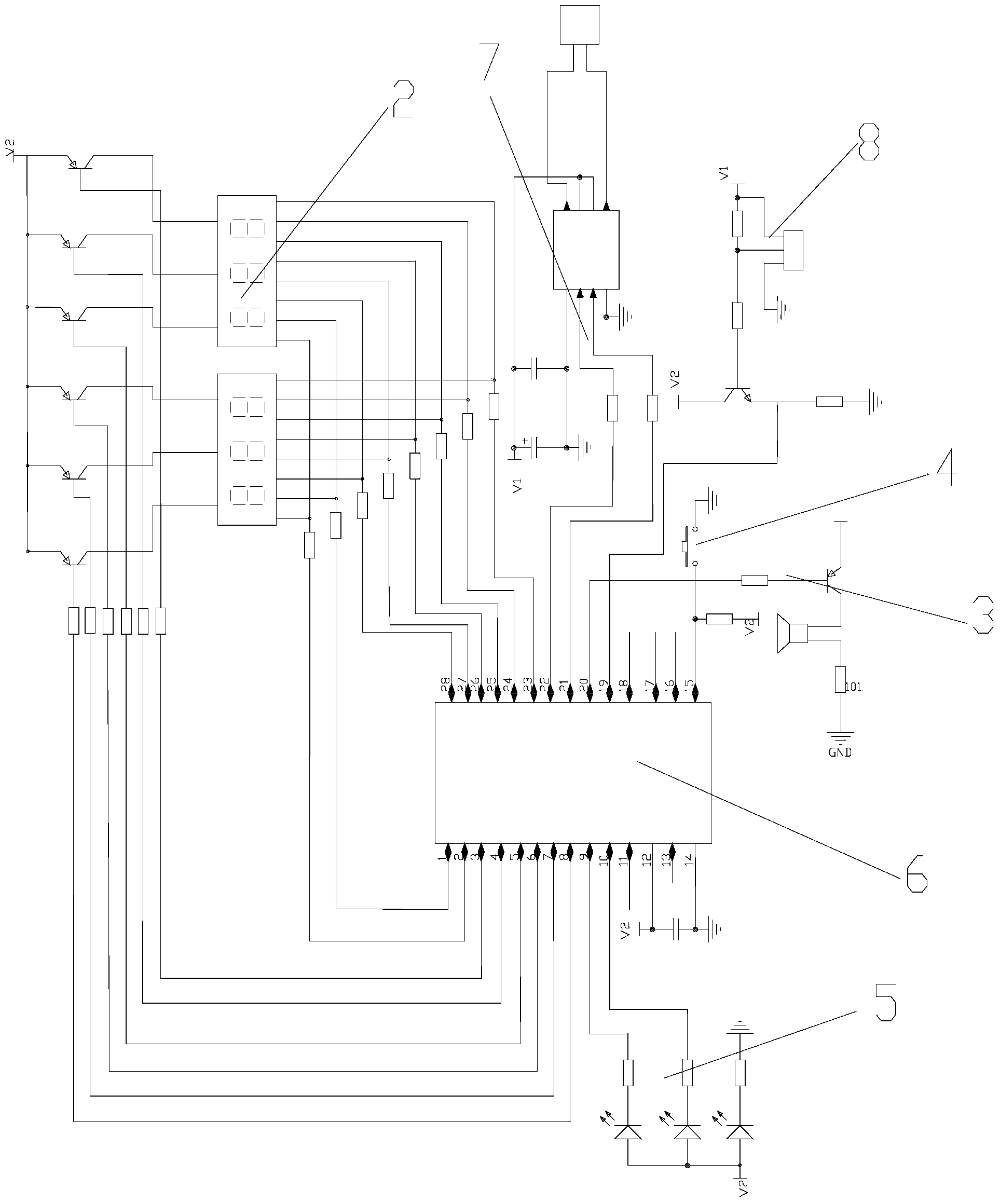

[0043] Figure 1 to Figure 7 Shown is a solenoid valve life test system of the present invention, which completes the test of the solenoid valve life by counting the effective switching times of the solenoid valve. figure 1 It includes a voltage stabilizing circuit module 1, a central control module 6 connected to the voltage stabilizing circuit module 1, a display module 2, a voice alarm module 3, a key module 4, an indicator light module 5, a solenoid valve driving module 7 and a flow detection module 8, wherein the stabilizing The voltage circuit module 1 is a DC stabilized power supply used to keep the output voltage constant when the load, ambient temperature, and circuit parameters change;

[0044] The display module 2 is used to display the number of effective switches of the solenoid valve and the auxiliary alarm indication;

[0045] Voice alarm module 3 is used to remind the sound alarm under the failure state;

[0046] The button module 4 is used to start the switch,...

Embodiment 2

[0051] refer to Figure 1 to Figure 7 As shown, a solenoid valve life test system of the present invention completes the test of the solenoid valve life by counting the effective switching times of the solenoid valve. figure 1 It includes a voltage stabilizing circuit module 1, a central control module 6 connected to the voltage stabilizing circuit module 1, a display module 2, a voice alarm module 3, a key module 4, an indicator light module 5, a solenoid valve driving module 7 and a flow detection module 8, wherein the stabilizing The voltage circuit module 1 is a DC stabilized power supply used to keep the output voltage constant when the load, ambient temperature, and circuit parameters change;

[0052] The display module 2 is an LED display module, which is connected to the central control module 6, receives the instructions sent by the central control module 6 and displays in time the number of times used to display the effective switching of the solenoid valve and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com