Heat exchange capability testing equipment of underground heat exchanger of ground source heat pump

A technology of underground heat exchanger and heat exchange capacity, which is used in the testing of machine/structural components, instruments, measuring devices, etc., to achieve the effects of high temperature testing accuracy, accurate testing, and stable flow control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

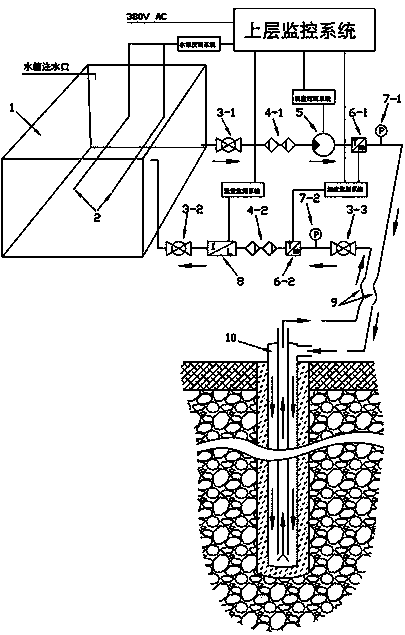

[0023] See attached figure 1 , the ground source heat pump underground heat exchanger heat exchange capacity testing equipment of the present invention, comprising insulation water tank 1, electric heater 2, copper ball valve, Y-shaped pipeline filter, stainless steel variable gear water pump 5, temperature sensor, pressure gauge, elbow Flowmeter 8; Described copper ball valve comprises first copper ball valve 3-1, the second copper ball valve 3-2, the 3rd copper ball valve 3-3; Described Y type pipeline filter comprises first filter group 4-1 and The second filter group 4-2; the temperature sensor includes a first temperature sensor 6-1 and a second temperature sensor 6-2; the pressure gauge includes a first pressure gauge 7-1 and a second pressure gauge 7-2 ;

[0024] The electric heater 2 is arranged in the thermal insulation water tank 1; the outer wall of the thermal insulation water tank 1 is provided with a water outlet and a water inlet; the water outlet of the therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com