A Method for Optimizing Structural Parameters of Single Winding Magnetic Levitation Switched Reluctance Motor

A technology of switched reluctance motor and structural parameters, applied in neural learning methods, electrical digital data processing, design optimization/simulation, etc., can solve the problems of general motor model accuracy, weakened effect, low calculation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

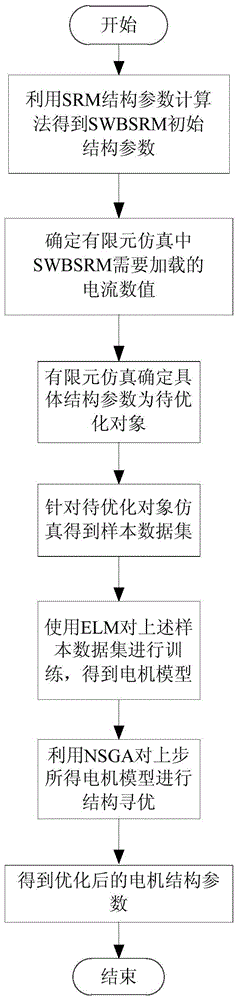

[0037] Below combined with Figure 2 to Figure 6 right figure 1 The technical scheme of the specific flow shown will be described in detail.

[0038] 1. When the predetermined performance parameters of the motor are: rated power P N =1.1kW, rated speed n N =2000r / min, rated voltage U N =220V, rated efficiency η=0.8, according to the traditional calculation method of SRM (Switched Reluctance Motor, switched reluctance motor) structure parameters, the structure of 12 / 8 structure SWBSRM (Single Winding Bearingless Switched Reluctance Motor, single winding magnetic levitation switched reluctance motor) can be obtained The initial value of the parameter is: rotor outer diameter D s =137mm, rotor outer diameter D a =70mm, inner diameter of rotor D i =31.5mm, stator yoke thickness h cs =10mm, rotor yoke thickness h cr =10mm, air gap length g=0.3mm, stator arc β s =15°, rotor pole arc β r =15°, the actual length of iron core l a =70mm, each pole stator winding N=85 turns. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com