Method and system for selection of thermal error temperature sensitive point based on comprehensive temperature information

A technology that integrates information and thermal errors. It is used in manufacturing computing systems, geometric CAD, design optimization/simulation, etc. It can solve problems such as unreasonable, high collinearity, and different numbers of temperature-sensitive points, so as to achieve a simple calculation process and avoid errors. the effect of judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

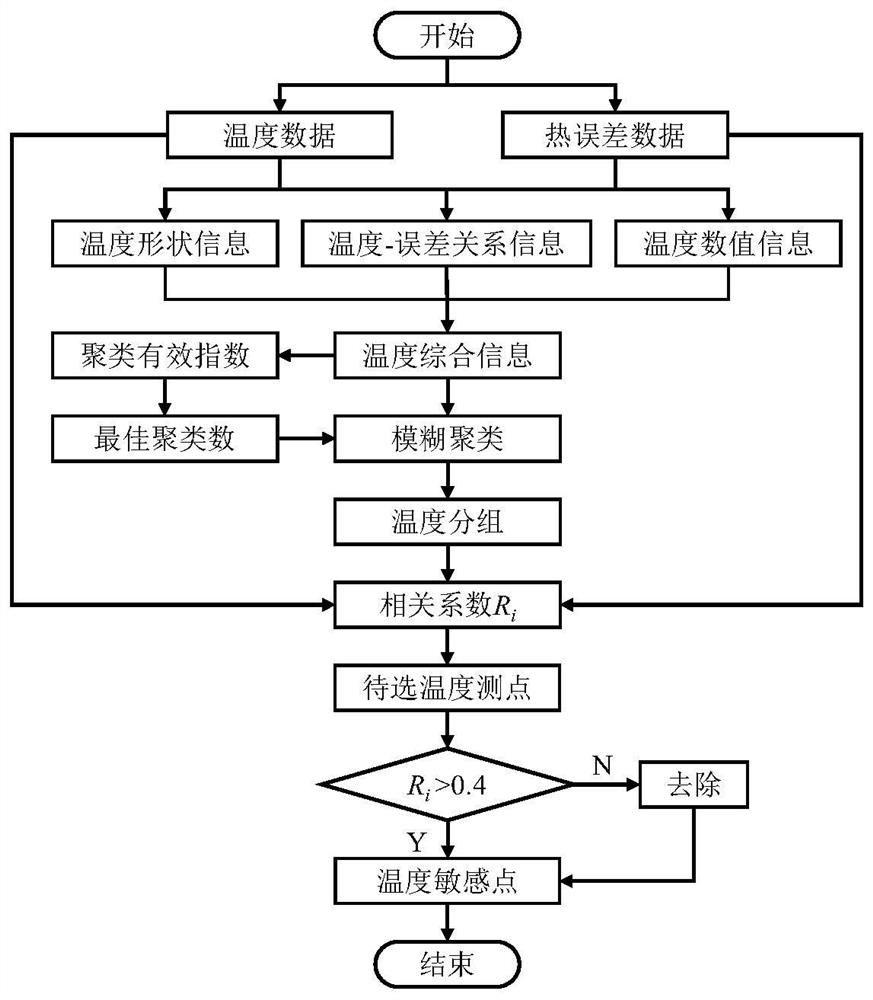

[0067] like figure 1 As shown, the method for selecting a temperature sensitive point for thermal error of a CNC machine tool spindle based on comprehensive temperature information provided by this embodiment includes the following steps:

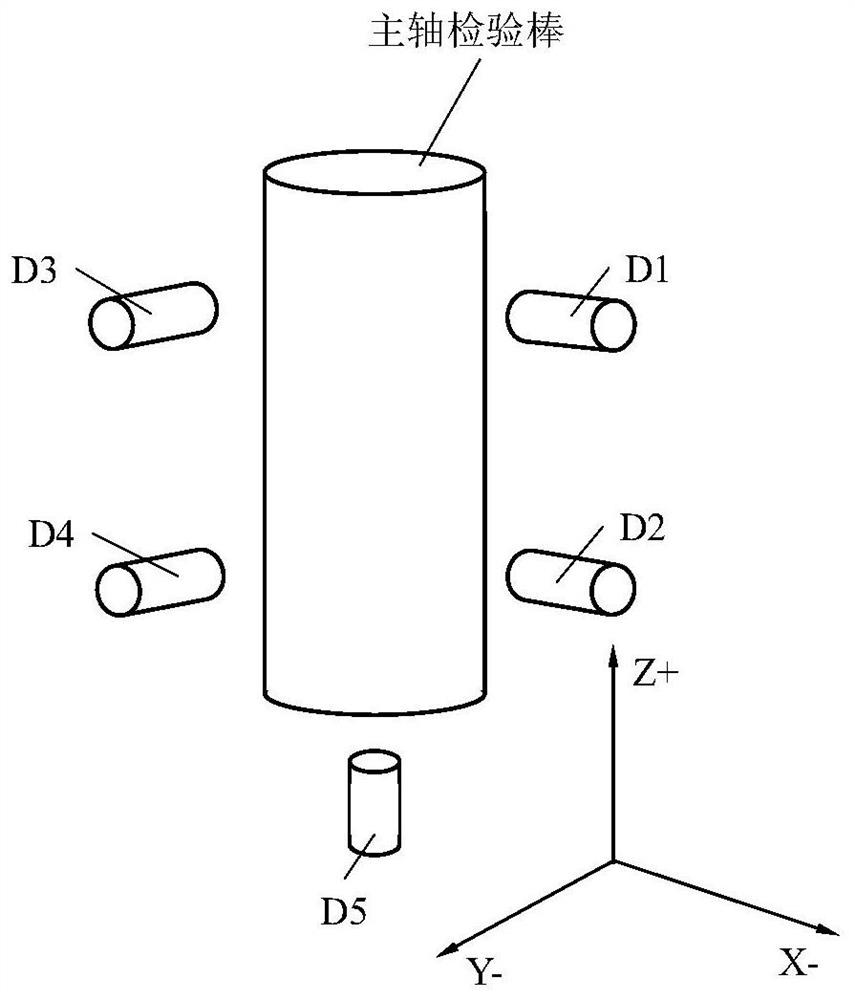

[0068] 1) Data collection: During the operation of the machine tool, temperature data and thermal error data are collected synchronously. The thermal error data is obtained according to the five-point method in ISO230-3, and the five thermal errors are the thermal drift error δ in the X direction. x , X-direction thermal deflection error ε x , Y-direction thermal drift error δ y , Y-direction thermal deflection error ε y , Z-direction thermal elongation error δ z . The temperature data is collected by using temperature sensors distributed in various parts of the CNC machine tool. The spindle speed refers to the variable speed map or constant speed in ISO230-3.

[0069] 2) Constructing a comprehensive temperature information matrix: U...

Embodiment 2

[0079] The method for selecting temperature sensitive points for thermal error of a CNC machine tool spindle based on comprehensive temperature information provided by this embodiment avoids the problem that the number of temperature sensitive points is the same under different thermal errors, and the temperature measuring points with similar shape of temperature curve but large difference in temperature value The phenomenon of being divided into two groups is reduced, and the number of selected temperature sensitive points is less. When used for modeling, the model has good performance. The method provided in this embodiment includes the following steps:

[0080] like figure 2 shown, figure 2 It is a schematic diagram of measuring thermal error by five-point method, in which D1-D5 are displacement sensors used to measure thermal error, and X-, Y-, and Z+ are machine tool coordinate systems.

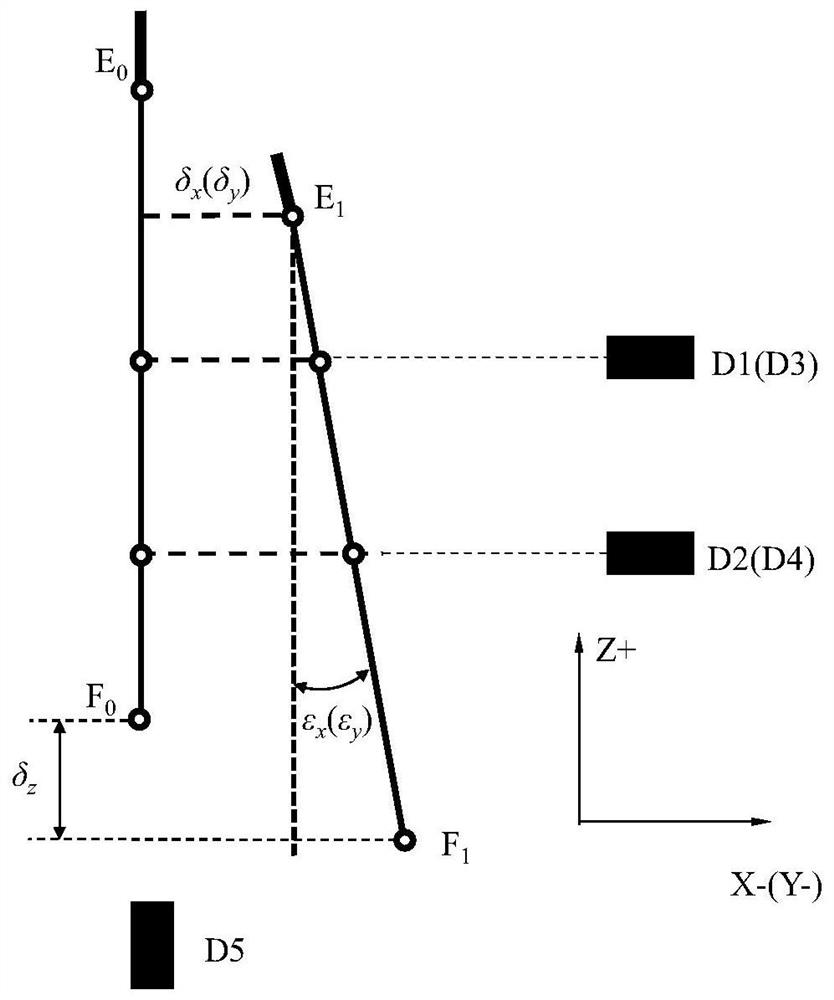

[0081] like image 3 shown, image 3 Generate a schematic for the five-term the...

Embodiment 3

[0130] The thermal error temperature sensitive point selection system based on comprehensive temperature information provided by this embodiment includes a memory, a processor, and a computer program stored in the memory and running on the processor. The processor implements the following when executing the program step:

[0131] 1) Data collection: collect the temperature data and thermal error data of the object to be measured;

[0132] 2) Build a comprehensive temperature information matrix: use the temperature data and thermal error data to build a comprehensive temperature information matrix;

[0133] 3) Determine the optimal number of clusters: Substitute the temperature comprehensive information matrix under different errors into multiple effective clustering indicators to obtain the optimal number of clusters under different effective clustering indicators, and finally determine the optimal number of clusters by voting ;

[0134] 4) Fuzzy clustering: use the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com