Stirring device for extrusion, cut-off and thermal insulation integrated machine

A technology of a stirring device and an all-in-one machine, which is applied in the direction of mixing/kneading of horizontal installation tools, can solve the problems of low work efficiency, high cost and large size, and achieves the effects of high work efficiency, low cost and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

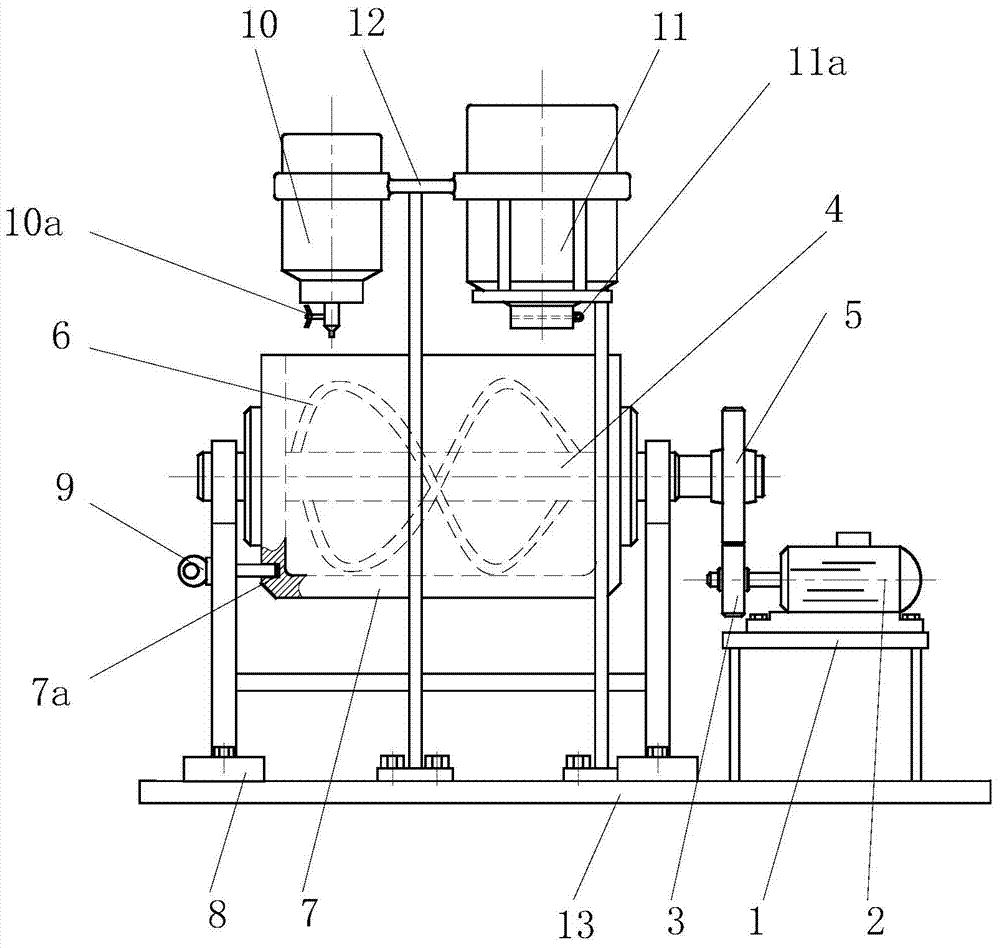

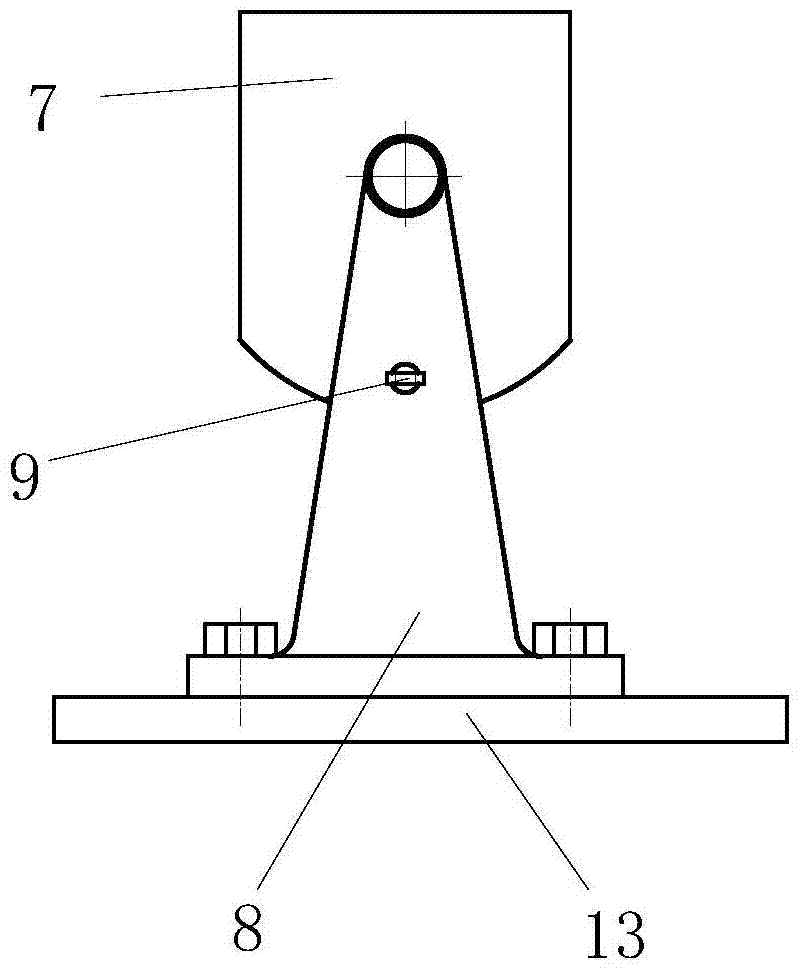

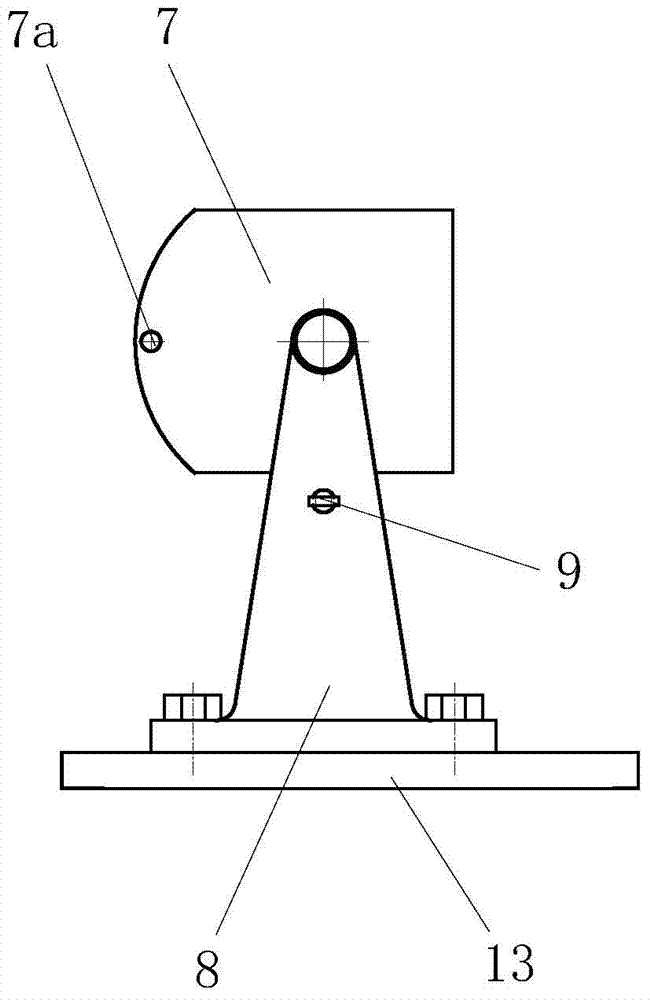

[0013] Such as Figure 1 to Figure 3 As shown, a mixing device for an extrusion, cutting and heat preservation machine includes a motor base 1, a motor 2, a driving gear 3, a transmission shaft 4, a driven gear 5, a stirring crank rod 6, a kneading box 7, and a box base 8. Stop pin 9, water supply bucket 10, flour bucket 11, bracket 12 and base 13, the motor base 1 is fixedly connected with the base 13, the motor 2 is installed on the motor base 1, and the output shaft end of the motor 2 is installed Drive gear 3 is arranged, and described drive gear 3 is meshed with driven gear 5, and described driven gear 5 is installed on transmission shaft 4 one end, and described transmission shaft 4 is installed on the kneading box 7, and the surface of described transmission shaft 4 A stirring c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap