Novel steam oven

A steam oven, a new type of technology, applied in the field of steam ovens, can solve the problems of large water vapor consumption, excessive overflow, water shortage and dry burning of water, etc., to achieve the effects of reducing water vapor consumption, prolonging service life, and accelerating heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

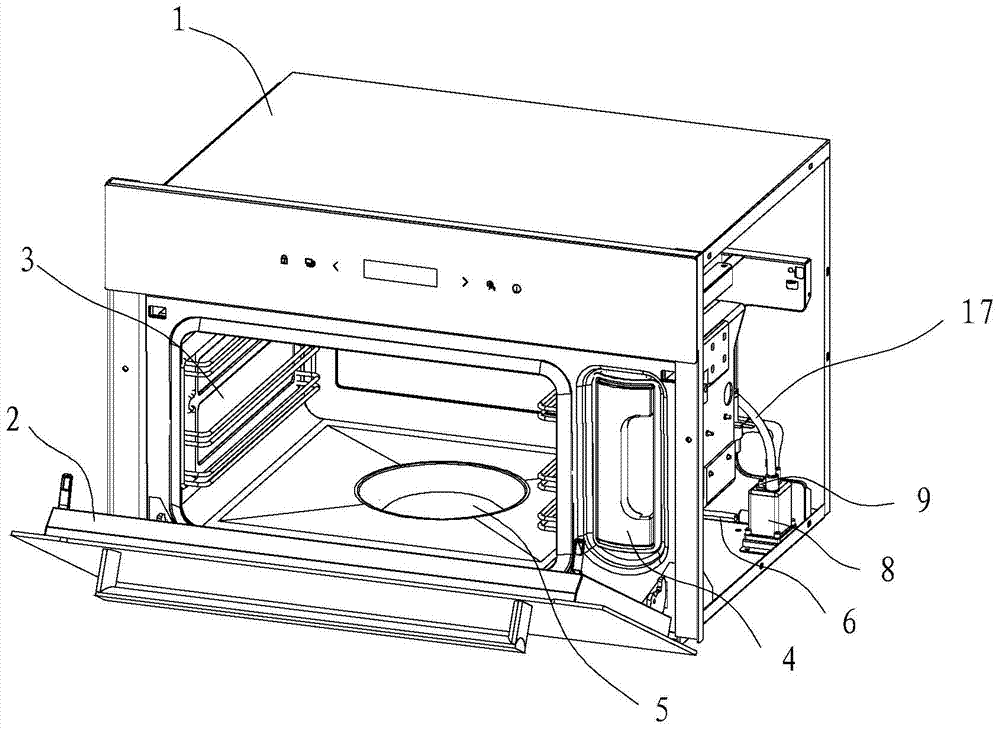

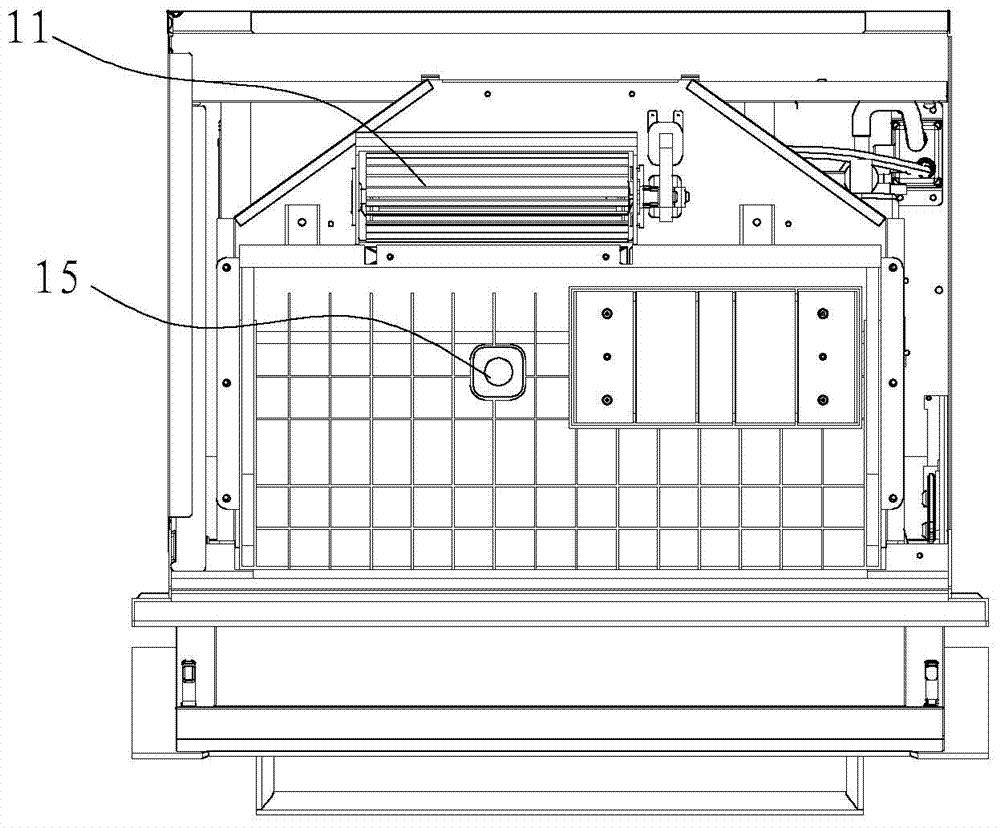

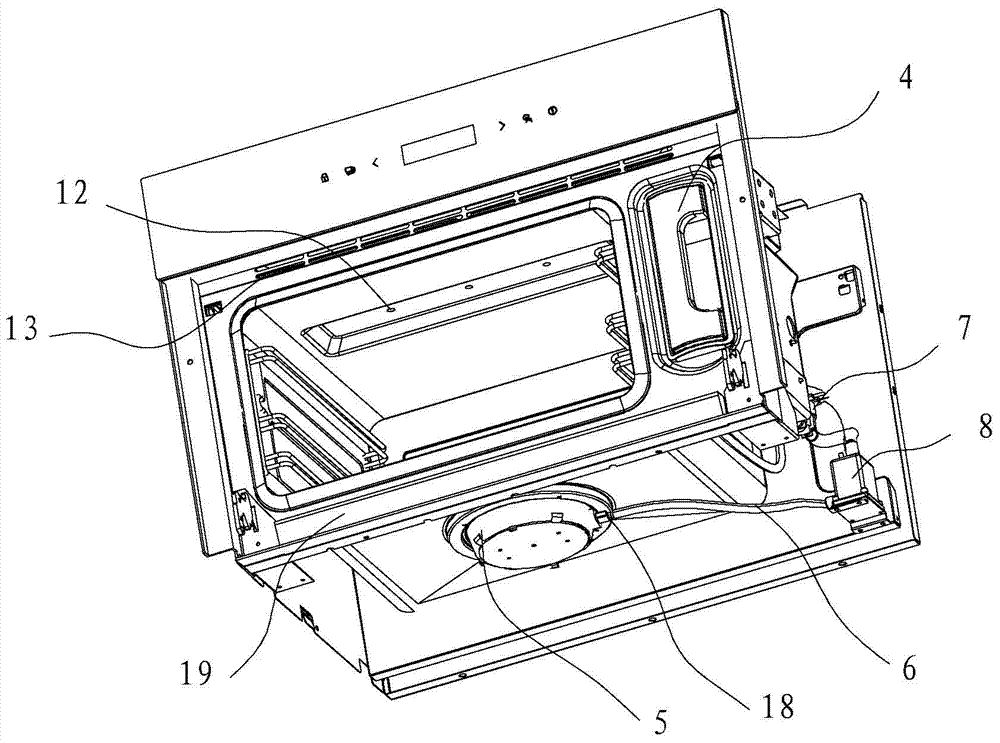

[0022] Embodiment 1: a kind of novel steam oven of present embodiment 1, as Figure 1 to Figure 4 As shown, it includes a furnace body 1, a furnace door 2, an inner tank 3, a water storage tank 4 and a controller. An integral stainless steel drawing body heating plate 5 for generating steam is provided at the bottom of the inner tank. The three side walls of the inner tank A synchronous line heating layer 14 for auxiliary heating is installed on the wall, a connecting water pipe 6 is provided between the water storage tank and the heating plate, and a water pump 7 controlled by a controller is installed on the connecting water pipe. The furnace body is designed with a water balance system and an air balance system. system, exhaust system and waterproof water guide system, the water balance system includes an auxiliary water tank 8, the auxiliary water tank is installed between the water pump and the heating plate and connected to each other through the connecting water pipe, th...

Embodiment 2

[0024] Embodiment 2: A new type of steam oven in this embodiment 2, including a furnace body, a furnace door, an inner tank, a water storage tank and a controller. System, exhaust system and waterproof water guide system. The exhaust system also includes a cooling device. The cooling device includes a number of heat sinks and confluence grooves placed in the exhaust cavity. The bottom plane of the exhaust cavity is inclined to the rear of the furnace body. The groove is designed at the rear of the exhaust chamber and communicates with the auxiliary water tank. The high-temperature steam discharged into the exhaust chamber flows through the heat sink to cool down and then is discharged out of the machine through the exhaust grid. The steam condensate falls and is discharged into the auxiliary water tank through the confluence groove Afterwards, it is used again to reduce the consumption of water. The other parts of the present embodiment 2 are similar to the corresponding parts ...

Embodiment 3

[0025] Embodiment 3: A new type of steam oven according to Embodiment 3, including a furnace body, a furnace door, an inner tank, a water storage tank and a controller. A heating plate is arranged at the bottom of the inner tank, and a water balance system and an air balance system are designed in the furnace body. System, exhaust system and waterproof water guide system. The exhaust system also includes a heat exchanger. The heat exchanger is installed in the water storage tank and placed under the horizontal plane. The inlet of the heat exchanger communicates with the steam outlet of the exhaust chamber, and the heat exchange The other outlet of the device is connected to the exhaust grid, and the high-temperature steam can heat the cold water in the water storage tank through the heat exchanger, fully recover the heat in the steam, reduce the heating energy of the heating plate, and achieve the purpose of energy saving. This embodiment 3 The other parts are similar to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com