Medical infusion device

An infusion device and liquid storage box technology, applied in the field of medical devices, can solve the problems of rapid drug solution, patient discomfort, and inability to drip at a uniform speed, and achieve the effects of small liquid level changes, reduced complexity, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

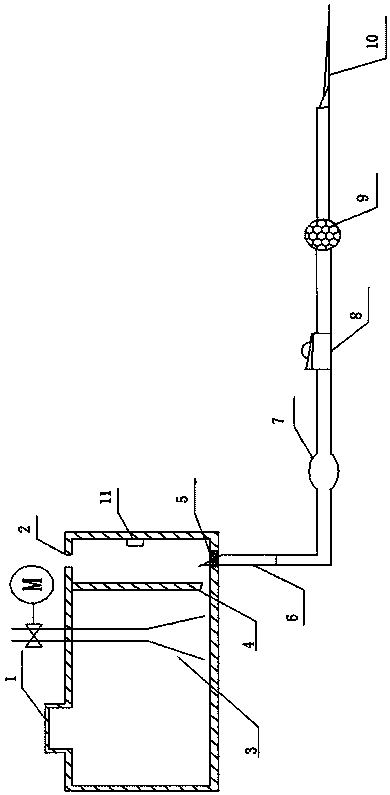

[0022] Such as figure 1 Shown: a medical infusion device, including a liquid storage box, a partition, an air guide tube 3, a liquid level sensor, an air intake valve, a motor, and a controller; the partition divides the liquid storage box into a left chamber and a right chamber; The volume of the chamber is greater than that of the right chamber; the bottom of the partition is provided with a communicating hole 4;

[0023] The air guide tube 3 is funnel-shaped, one end with a larger opening is located at the bottom of the left chamber, and the other end is located outside the top of the left chamber; the port of the air guide tube 3 located outside the top of the left chamber is provided with an air inlet valve ; The liquid level sensor is arranged in the middle of the inner surface of the side wall of the right chamber;

[0024] The signal detected by the liquid level sensor 11 is input to the controller, and the controller controls the motor to open or close the intake val...

Embodiment 2

[0027] Embodiment 2: On the basis of Embodiment 1, the controller adopts AT89S51 single-chip microcomputer.

Embodiment 3

[0028] Embodiment 3: On the basis of embodiment 1, the volume of the left chamber is 800 milliliters, and the volume of the right chamber is 10 ml.

[0029] The working principle of the present invention: after adding liquid medicine to the left chamber, the liquid medicine in the right chamber will submerge the liquid level sensor. Since the volume of the right chamber is very small, the liquid level will soon be equal to that of the liquid level sensor in the right chamber. Once the liquid level is lower than the height of the liquid level sensor, the controller controls the intake valve so that the air quickly enters the left chamber through the air duct, the pressure at the bottom of the left chamber will increase, and the liquid in the left chamber will Enter the right chamber through the communication hole, and then the liquid level in the right chamber is equal to the liquid level sensor again, so the liquid level in the right chamber is almost constant all the time, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com