Particle crushing dryer window structure

A dryer and window technology, which is applied in the window structure field of particle crushing dryer, can solve the problem of difficult to observe the working state of the window, and achieve the effect of reducing waste of resources and improving production value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

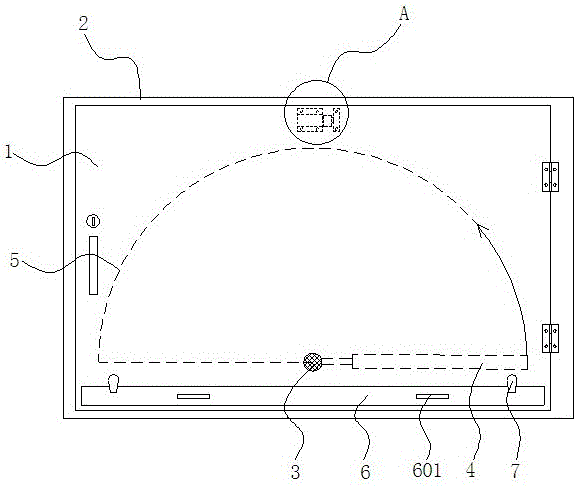

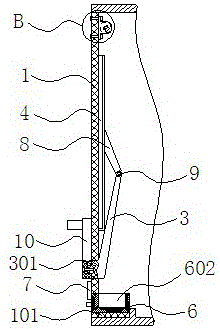

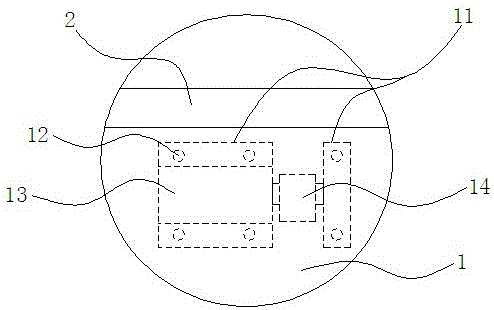

[0015] Now in conjunction with accompanying drawing, the present invention will be further described.

[0016] Such as figure 1 , figure 2 As shown, the main body of the window structure of the particle crushing dryer is a transparent window plate 1, and the window plate 1 is connected to the box body 2 corresponding to the particle crushing dryer in the form of a hinge. A dust scraper is installed on the inside of the window plate 1, and the dust scraper is mainly composed of a support 3, a skeleton 8, a torsion spring 9, a brush body 4, and a hinge. The brush body 4 is elongated, and is fixed on the framework 8 by bonding or screws, and one end of the framework 8 is hinged to one end of the bracket 3 through a hinge, and a torsion spring 9 is installed at the hinged part, and the torsion spring 9 impels the framework 8 to move The brush body 4 is pressed against the inner surface of the window plate 1 . The other end of the bracket 3 is provided with a rotating shaft 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com