Powder electrostatic spraying system

An electrostatic spraying and powder technology, applied in the direction of electrostatic spraying device, liquid spraying equipment, spraying device, etc., can solve the problems of dust polluted air, explosion hazard of spraying room, etc., and achieve the effect of protecting the environment, improving working conditions and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

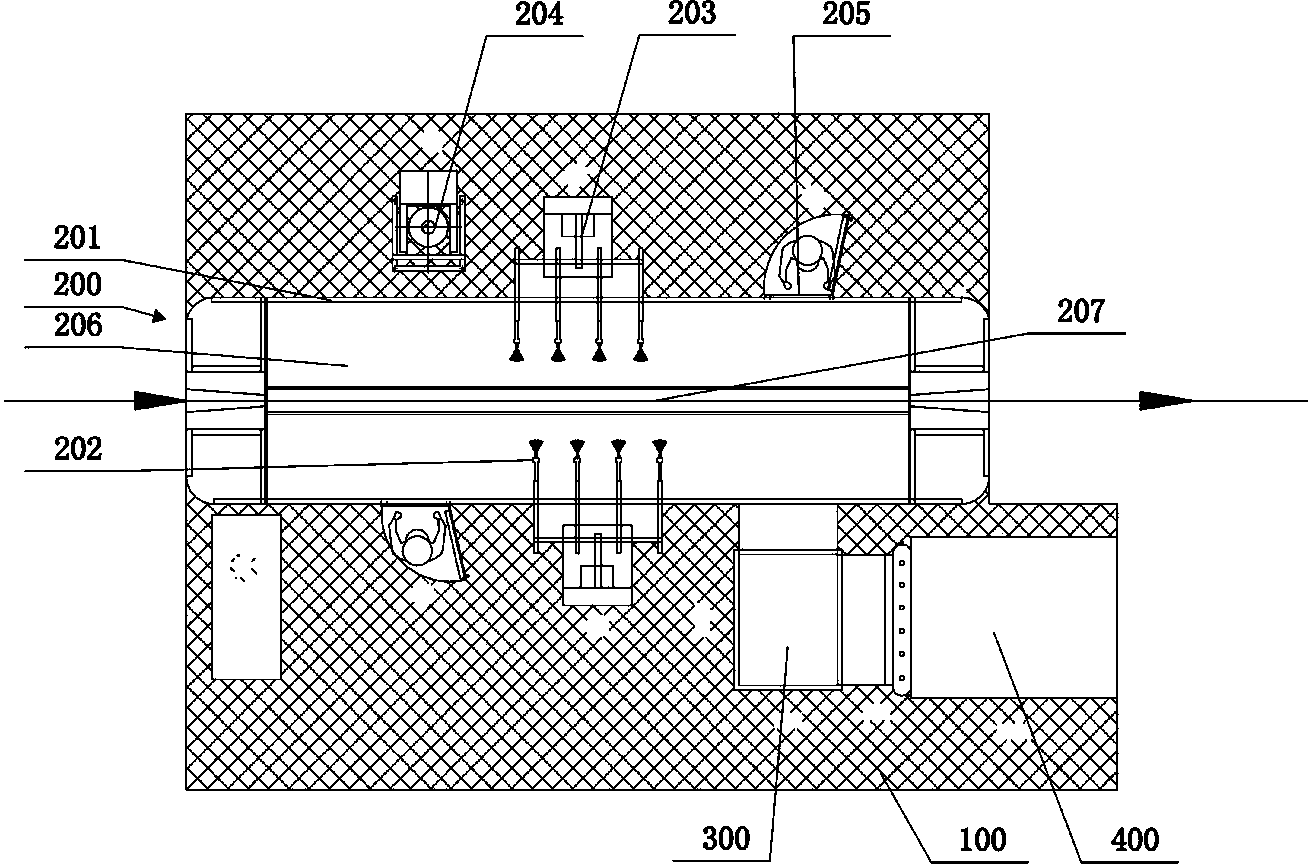

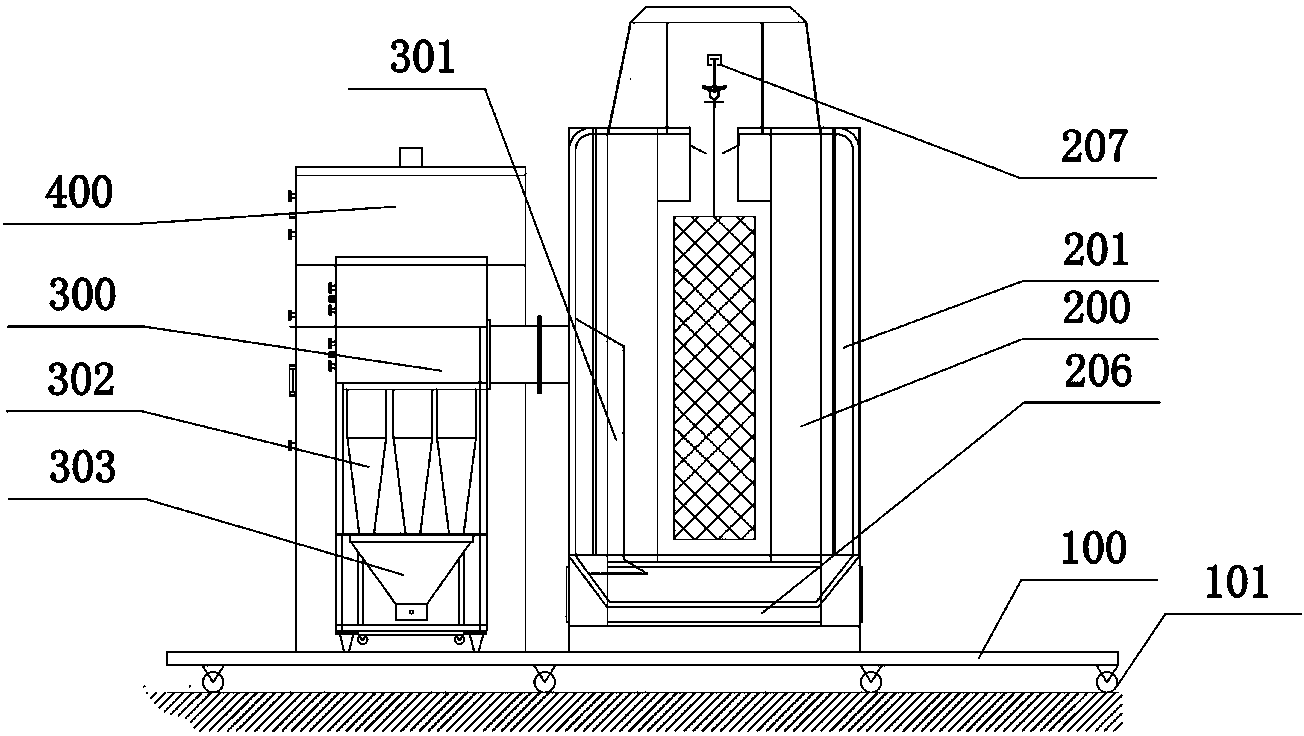

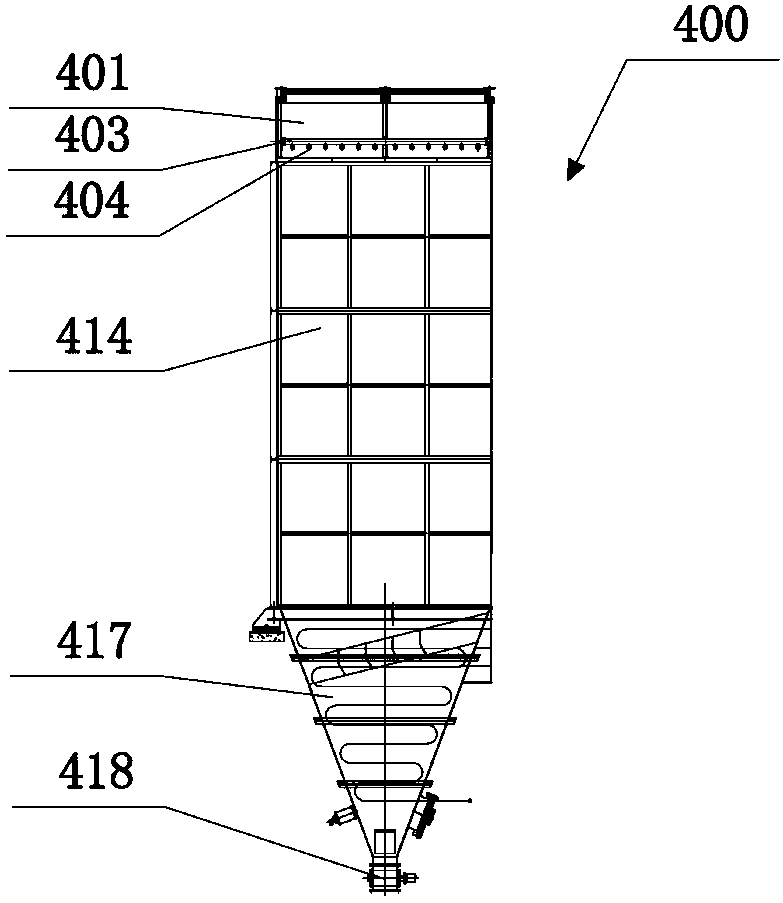

[0021] The powder electrostatic spraying system includes a workbench 100 on which a spray booth 200, a multi-pipe cyclone separator 300 and a filter 400 are installed, and a group of rollers 101 are arranged under the workbench 100 to facilitate the movement of the workbench 100 , increasing the flexibility of the spraying system. The whole system is compact in structure and occupies a small area.

[0022] The spray booth 200 includes side panels 201 and a bottom panel 206 . There are two side plates 201, which are installed on both sides of the bottom plate 206 respectively. The bottom plate 206 is fixedly mounted on the workbench 100 . A spray gun 202 is installed on the side plate 201 . Preferably, four comb-shaped spray guns 202 are installed on each side plate 201 , and the spray guns 202 are parallel to each other. The spray guns 202 on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com